Best Prop For Speed

Best Prop For Speed Related Searches

High Performance Boat Props 4 Blade Prop Props For Sale Uk Peri Push Pull Props Peru Props Prop Pitch Motor For Sale Front Bumpers For Cars Outboard Propeller Repair Boat Prop Guard Mercury Props For Sale Best Overall Pickup Truck Premium Car Accessories Boat Prop Lock Car Accessories For Interior Best Grinder To Buy Car Extra Fittings Stearman Propeller For Sale Used Yamaha Props For Sale Outboard Propeller Calculator Rmd Push Pull Props Hanging Accessories For Car Revolution 4 Propeller For Sale Most Stable Car Highest Rated Pickup Truck Girl Accessories For Cars Light Accessories For Cars Large Ship Propeller For Sale Better Auto Rubber Fixing Front Bumper Shisham PropsBest Prop For Speed Supplier & Manufacturer from China

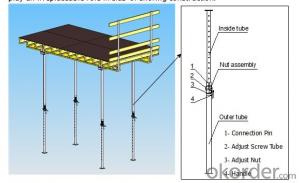

Best Prop For Speed is a collection of high-quality products designed to enhance the performance and efficiency of various vehicles. These products are engineered to provide optimal results, ensuring that users experience a significant improvement in their vehicle's speed and overall performance. The product line includes a range of components, such as propellers, gears, and other essential parts, which are meticulously crafted to meet the demands of high-speed applications.Best Prop For Speed products are widely used in various scenarios, including marine, aviation, and automotive industries. These products are particularly beneficial for applications that require high-speed propulsion, such as racing boats, high-performance aircraft, and fast cars. By incorporating Best Prop For Speed components into their systems, users can expect to achieve greater speeds, improved fuel efficiency, and enhanced overall performance.

Okorder.com is a leading wholesale supplier of Best Prop For Speed products, boasting a large inventory that caters to the diverse needs of customers across different industries. With a commitment to providing top-notch products and exceptional customer service, Okorder.com ensures that customers receive the best possible experience when purchasing Best Prop For Speed components. By offering a comprehensive selection of high-quality products at competitive prices, Okorder.com has established itself as a trusted source for Best Prop For Speed products.

Hot Products