Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

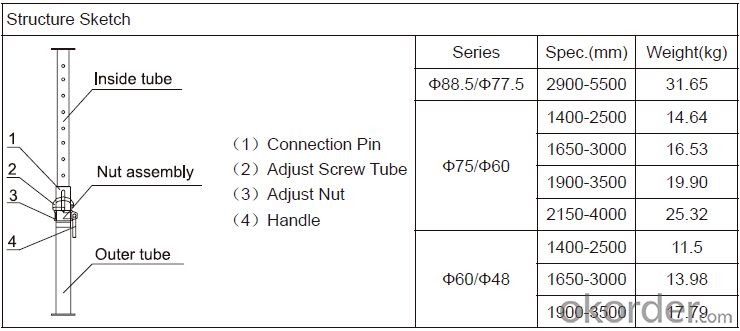

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

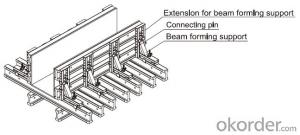

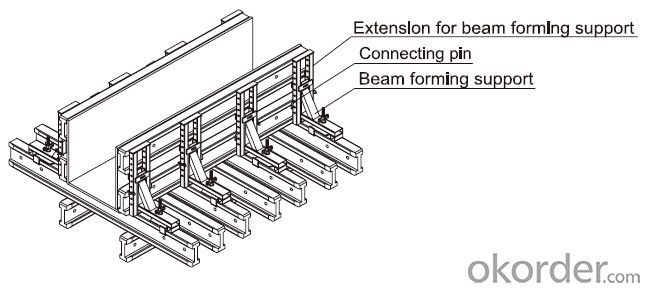

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: What are the common load testing procedures for steel props?

- Load testing procedures for steel props commonly involve the following steps: 1. Preparing the props: Before conducting load testing, it is important to ensure that the steel props are in good condition and free from any defects or damage. Any rust or corrosion should be removed, and all components should be properly assembled and secured. 2. Determining the load capacity: The load capacity of steel props should be determined based on the manufacturer's specifications or industry standards. This information can usually be found in the product manual or technical data sheet. It is crucial to adhere to these guidelines to ensure accurate load testing. 3. Setting up the test equipment: Load testing requires specialized equipment such as load cells, hydraulic jacks, or weights. The equipment should be properly calibrated and positioned to accurately measure the applied load. The props should be securely fixed in place to prevent any movement during the testing process. 4. Applying the load: The load should be gradually applied to the steel props in a controlled manner. This can be done by incrementally increasing the load using the chosen testing equipment. It is important to monitor the props throughout the process to ensure they are not exceeding their load capacity or displaying any signs of failure. 5. Monitoring and recording data: During the load testing, it is essential to continuously monitor the props and record relevant data such as applied load, deflection, and any visual changes or deformations. This data will help assess the performance and structural integrity of the steel props. 6. Analyzing the results: After completing the load testing, the gathered data should be analyzed to evaluate the props' performance. This analysis may involve comparing the recorded values against the manufacturer's specifications or industry standards. Any signs of failure, excessive deflection, or other anomalies should be carefully assessed and addressed. 7. Reporting and documentation: A comprehensive report should be prepared summarizing the load testing procedures, results, and any observations made during the process. This report should be securely stored as part of the project documentation for future reference. It is important to note that load testing procedures may vary depending on specific project requirements, industry standards, or regional regulations. Therefore, it is recommended to consult with relevant experts or follow specific guidelines provided by the steel prop manufacturer.

- Q: Can steel props be used in highway construction?

- Yes, steel props can be used in highway construction. Steel props are commonly used as temporary support structures during the construction of highways. They provide stability and reinforcement to the structures being built, ensuring safety and durability.

- Q: How do steel props contribute to the prevention of structural instability?

- Steel props, also known as adjustable steel props or acrow props, play a crucial role in preventing structural instability in various construction projects. These props are vertical supports made from high-quality steel, typically consisting of a tube with an adjustable inner section and a threaded outer section. First and foremost, steel props help distribute the load evenly across the structure, ensuring that the weight of the building or temporary structure is adequately supported. By providing additional support to walls, floors, and other load-bearing elements, they help prevent overloading and potential structural failure. Moreover, steel props are adjustable, allowing them to be set at specific heights and lengths. This adjustability is essential in maintaining stability as it enables construction teams to precisely position the props to support weak or unstable areas. By providing temporary reinforcement in these areas, steel props help prevent further movement or collapse until permanent measures can be implemented. Additionally, steel props are designed to withstand heavy loads and can be used in various construction scenarios, such as during the construction of walls, beams, or floors. They can bear significant weight and provide reliable support, reducing the risk of structural instability. Furthermore, steel props are often used in conjunction with other support systems, such as scaffolding, to enhance stability and safety. When combined with scaffolding, they provide additional reinforcement to the entire structure, minimizing the potential for structural failure and ensuring the safety of workers and the public. In summary, steel props contribute to the prevention of structural instability by distributing loads evenly, providing temporary reinforcement in weak or unstable areas, withstanding heavy loads, and working in tandem with other support systems. Their adjustability and strength make them an essential tool in construction projects, ensuring stability and safety throughout the construction process.

- Q: Can steel props be used in supporting temporary exhibition booths?

- Temporary exhibition booths can indeed benefit from the use of steel props. These props provide a robust and dependable support system for structures of this nature. They offer the added advantage of adjustability, as their height can be modified to accommodate various locations or uneven surfaces. Moreover, steel props are highly regarded for their ability to bear heavy loads, making them an ideal choice for supporting exhibition materials, displays, and equipment. Furthermore, their durability and resistance to wear and tear ensure the stability and safety of the temporary booth throughout its usage. All in all, steel props are widely favored in the construction and support of temporary exhibition booths due to their strength, versatility, and reliability.

- Q: How much is the glass floor cost. That's the kind of steel frame

- Design parameters related to the thickness of the glass, whether or not coated, hollow specifications, spotlights requirements, size, color, glass brand

- Q: Can steel props be used for temporary support in telecommunications cable installation?

- Yes, steel props can be used for temporary support in telecommunications cable installation. Steel props provide strong and stable support for cables, ensuring the safety and proper installation of the telecommunications infrastructure.

- Q: Why subway steel erection erection to the design elevation of 800

- First -0.4m; -4.3 m; third -7.8m; -11.0 m; fifth -14.2 M.

- Q: How do steel props compare to wooden props?

- Steel props are generally considered to be more durable and sturdy compared to wooden props. They can withstand higher loads and are less prone to bending or warping. Steel props also offer more versatility in terms of height adjustment and can be easily secured in place. However, wooden props are often preferred for lighter loads and temporary support due to their cost-effectiveness and ease of handling. Ultimately, the choice between steel and wooden props depends on the specific requirements of the project and the load-bearing capacity needed.

- Q: Are steel props suitable for use in modular construction projects?

- Yes, steel props are suitable for use in modular construction projects. Steel props are strong, durable, and adjustable, making them ideal for supporting the weight of modular construction components. They provide stability and ensure the structural integrity of the modular units during assembly and transportation. Additionally, steel props are versatile, easy to install, and can be easily adjusted to accommodate different heights and angles, making them a reliable choice for modular construction projects.

- Q: Are steel props suitable for use in temporary shoring?

- Temporary shoring can utilize steel props, also referred to as adjustable steel props or steel shore props. These props are commonly employed in construction to provide temporary support while formwork and scaffolding are being erected. Steel props have numerous advantages that render them suitable for temporary shoring. Firstly, their durability allows them to withstand heavy loads, making them ideal for supporting concrete slabs, beams, and other structural elements. Their sturdy construction ensures stability and eliminates the risk of collapse or failure. Furthermore, the adjustability of steel props enables precise height adjustments to meet various shoring requirements. This feature makes them versatile and appropriate for different construction applications. Typically, props are equipped with a threaded screw mechanism or a hydraulic system, simplifying adjustment and ensuring secure positioning. Moreover, steel props are cost-effective and reusable. They can be easily disassembled, transported, and reused in multiple construction projects, reducing the need for frequent purchases and minimizing waste. This practicality makes them an excellent choice for temporary shoring, providing long-term cost savings. In conclusion, steel props are indeed suitable for temporary shoring. Their durability, adjustability, and cost-effectiveness make them an excellent option for providing temporary support during construction projects. However, it is essential to ensure that steel props are designed, installed, and maintained according to industry standards and guidelines to guarantee their safe and effective use.

Send your message to us

Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords