Structural Columns And Beams

Structural Columns And Beams Related Searches

Steel Structure Beam Column Connection Structural Insulated Panels Steel Column To Steel Beam Connection Lightweight Structural Panels Joining Steel Beams Structure Pipe Structural Insulated Panels Australia Crane And Rigging Column Splices Refractories And Industrial Ceramics Basics Of Structural Engineering Bolting Steel Beams Together Modular Roof Panels Beam Joints Liners And Covers Structural Insulated Panels India Sip Structural Insulated Panel Stainless Steel I Beam Engineered Steel Buildings Styrofoam Building Panels Curtain Panels Wire And Wood Fence Panels Architectural Exterior Wall Panels Steel Column Connection To Foundation Steel Screws Drainage Fittings Simple Beam Pre Engineered Steel Structure Construction Props Forming ConcreteStructural Columns And Beams Supplier & Manufacturer from China

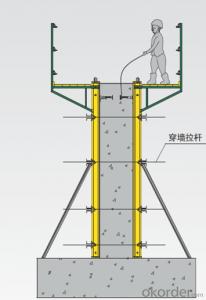

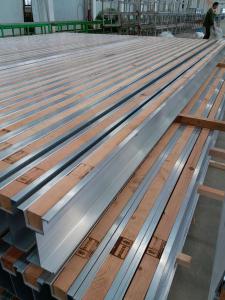

Structural Columns and Beams are essential components in the construction industry, providing critical support and stability to various structures. These products are designed to withstand significant loads and are commonly used in building frameworks, bridges, and other infrastructure projects. Their primary function is to maintain the structural integrity of a construction, ensuring safety and durability.Structural Columns and Beams are widely utilized in both residential and commercial construction projects, as well as in civil engineering endeavors. They can be found in the form of steel, concrete, or a combination of both materials, depending on the specific requirements of the project. These products are engineered to meet various load-bearing capacities and are essential for creating a robust and reliable framework.

Okorder.com is a leading wholesale supplier of Structural Columns and Beams, offering a vast inventory to cater to the diverse needs of the construction industry. With a commitment to quality and customer satisfaction, Okorder.com ensures that these products are available at competitive prices and in a timely manner, making it a reliable choice for contractors and engineers alike.

Hot Products