Steel Frame Formwork for Column Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Column Steel Frame Formwork Description

With adjustable flexiable sizes of frame, the column steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean with column formwork. As the framework, it is adapted to the plywood with thickness of 18mm. High-precision production line guarantees the perfect products.

2. Main Features of Column Steel Frame Formwork

◆ Allowable pressure is 80KN/m2 .

◆ Faster and easy operation.

◆ The dimension for column is adjustable.

- We can special design according to any requirements.

3. Column Steel Frame Formwork Specifications

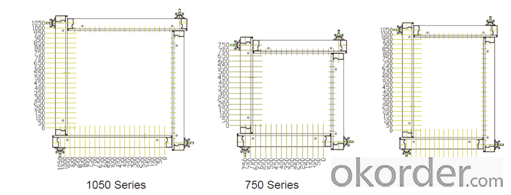

4. Column Steel Frame Formwork Images

5. FAQ of Column Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: What are the different types of concrete surface finishes achievable with steel frame formwork?

- Steel frame formwork allows for the attainment of various concrete surface finishes. These include: 1. Smooth Finish: The most commonly achieved finish with steel frame formwork. It yields a smooth and uniform surface suitable for most applications. It is attained by ensuring proper alignment of the formwork and correct pouring and vibration of the concrete. 2. Exposed Aggregate Finish: This finish involves the use of specialized formwork with inserts or panels featuring a textured surface. When concrete is poured into the formwork, the textured surface creates a pattern or design on the final concrete surface. This finish is often used for decorative purposes, such as sidewalks, driveways, and outdoor patios. 3. Stamped Finish: A stamped finish is attained by employing steel frame formwork with imprinted patterns or designs on its surface. Once the concrete is poured and cured, the formwork is removed, leaving behind a concrete surface with the desired pattern. This finish is commonly used for decorative flooring or walls. 4. Polished Finish: A polished finish is achieved using steel frame formwork with a smooth and flat surface. After pouring and curing the concrete, special tools and techniques are used to polish it, resulting in a glossy and reflective surface. This finish is often employed in upscale applications like commercial buildings, showrooms, or museums. 5. Textured Finish: This finish is accomplished by utilizing steel frame formwork with a textured surface, such as a pattern or design. Once the concrete is poured and cured, the formwork is taken off, revealing a concrete surface with the desired texture. This finish is frequently used in areas requiring a non-slip or non-skid surface, such as parking garages or industrial floors. To summarize, steel frame formwork offers a wide range of possibilities for achieving diverse concrete surface finishes. Whether you seek a smooth and even surface, an exposed aggregate finish, a stamped design, a polished appearance, or a textured surface, steel frame formwork can help you attain the desired outcome.

- Q: What are the different types of connection details used with steel frame formwork?

- There are several different types of connection details that can be used with steel frame formwork in construction projects. These connection details are crucial for ensuring stability and strength in the formwork system. Some of the commonly used connection details include: 1. Wedge connections: This type of connection involves using wedge-shaped connectors that are inserted into pre-drilled holes in the steel frames. The wedges are then tightened to secure the frames together, creating a strong and stable connection. 2. Pin connections: Pin connections involve using steel pins or bolts to connect the steel frames together. The pins are inserted through pre-drilled holes in the frames and secured with nuts or other fasteners. This type of connection provides a strong and rigid joint between the frames. 3. Clamp connections: Clamp connections are achieved by using specially designed clamps that grip the steel frames together. The clamps are tightened using bolts or other fasteners, creating a secure connection between the frames. This type of connection is commonly used in situations where quick assembly and disassembly of the formwork is required. 4. Welded connections: Welded connections involve permanently joining the steel frames together using welding techniques. This type of connection provides maximum strength and stability but requires skilled welders and additional time for fabrication and installation. 5. Hybrid connections: Hybrid connections combine different types of connection details to achieve the desired level of strength and stability. For example, wedge connections can be used in combination with pin connections to enhance the overall rigidity of the formwork system. The choice of connection details will depend on various factors such as the specific project requirements, the load conditions, the desired level of formwork reusability, and the available equipment and resources. It is essential to consult with structural engineers and formwork specialists to determine the most suitable connection details for a particular steel frame formwork system.

- Q: What are the common quality control inspections for steel frame formwork installations?

- Some common quality control inspections for steel frame formwork installations include: 1. Dimensional Accuracy: This inspection ensures that the steel frames are fabricated to the correct dimensions and specifications as per the design drawings. It involves checking the lengths, widths, and heights of the frames to ensure they meet the required tolerances. 2. Welding Inspection: Steel frames are often assembled through welding, so a welding inspection is crucial to ensure the quality and strength of the joints. This inspection involves checking the welds for proper penetration, alignment, and absence of defects such as cracks or porosity. 3. Surface Quality: The surface of the steel frames should be free from any defects that could affect their performance or durability. A surface quality inspection involves checking for rust, corrosion, burrs, sharp edges, or any other imperfections that could impact the formwork's functionality. 4. Alignment and Levelness: It is essential to inspect the alignment and levelness of the steel frames to ensure that they are installed accurately. This inspection involves using laser levels, plumb bobs, or other measuring tools to check the vertical and horizontal alignment of the frames. 5. Anchorage Inspection: Steel formwork frames are often anchored to the structure using various methods, such as bolts or concrete embeds. An anchorage inspection involves checking the adequacy and proper installation of these anchorages to ensure the stability and safety of the formwork system. 6. Load Capacity Testing: Steel frame formwork installations should be capable of supporting the intended loads without failure or deformation. Load capacity testing involves applying the expected loads to the formwork system and monitoring its response to ensure it meets the required strength and stability criteria. 7. Safety Inspection: Formwork installations should comply with safety standards and regulations. A safety inspection involves checking for the presence and proper installation of safety features such as handrails, toe boards, and access platforms. It also includes ensuring that all workers involved in the installation are using appropriate personal protective equipment. These inspections are conducted at various stages, including during fabrication, assembly, and installation of the steel frame formwork. They help ensure the quality, reliability, and safety of the formwork system, minimizing the risk of accidents, delays, or structural failures during the construction process.

- Q: Can steel frame formwork be used for both slab and foundation construction?

- Yes, steel frame formwork can be used for both slab and foundation construction. Steel frame formwork is a versatile and durable system that allows for the efficient construction of both slabs and foundations. It provides a strong and stable structure for pouring concrete and ensures accurate and precise construction. The steel frame formwork system can be easily assembled and disassembled, making it suitable for various project requirements. Whether it is a slab or foundation, steel frame formwork can be adjusted and customized to meet the specific needs of the construction project.

- Q: What are the safety precautions for working with steel frame formwork?

- When working with steel frame formwork, there are several important safety precautions that should be followed to ensure the well-being of workers and prevent accidents. 1. Personal Protective Equipment (PPE): It is crucial for workers to wear the appropriate PPE, including safety helmets, safety glasses, gloves, and steel-toed boots. This protective gear helps to minimize the risk of head injuries, eye injuries, hand injuries, and foot injuries. 2. Training and Education: Workers should receive proper training and education on the use of steel frame formwork. This includes understanding the equipment, its limitations, and how to safely assemble and dismantle it. Adequate training helps to prevent accidents caused by human error or negligence. 3. Inspection and Maintenance: Regular inspection and maintenance of steel frame formwork are essential. It is important to check for any damaged or worn-out components, such as bolts, joints, or scaffolding. Any faulty or defective parts should be repaired or replaced immediately to avoid potential accidents. 4. Secure Foundation: The formwork should be set up on a stable and level foundation. This helps to prevent any sudden collapse or shifting of the structure, reducing the risk of accidents. The ground should be adequately prepared and compacted before placing the formwork. 5. Secure Anchoring: Steel frame formwork should be properly anchored or supported to prevent any movement or collapse during construction activities. This can be achieved by using sturdy braces, ties, or supports to ensure stability and structural integrity. 6. Fall Protection: Adequate fall protection measures should be in place. This includes installing guardrails, safety nets, or personal fall arrest systems (PFAS) to prevent workers from falling from heights. It is essential to provide proper training on the use of fall protection equipment and ensure its correct installation. 7. Communication: Clear communication among workers is crucial for maintaining safety. Workers should be trained to use appropriate hand signals or communication devices to coordinate their movements and avoid any potential accidents. 8. Safe Lifting and Handling: Workers should be trained on safe lifting techniques and the proper use of lifting equipment, such as cranes or hoists, to minimize the risk of back injuries or strains. 9. Weather Conditions: Extreme weather conditions, such as heavy rain, strong winds, or freezing temperatures, can affect the stability and safety of steel frame formwork. It is important to monitor weather forecasts and take appropriate measures, such as suspending work during adverse conditions or providing additional support to the structure. 10. Emergency Preparedness: Workers should be aware of emergency procedures, such as evacuation routes, first aid locations, and the location of fire extinguishers. Regular drills and training sessions on emergency response can help ensure workers are prepared to handle any unexpected situations. By following these safety precautions, workers can significantly reduce the risk of accidents and injuries when working with steel frame formwork. It is important to prioritize safety at all times and take necessary measures to create a secure working environment.

- Q: Can steel frame formwork be used for precast wall panels?

- Yes, steel frame formwork can be used for precast wall panels. Steel frame formwork is commonly used in construction projects, including the production of precast wall panels. Steel formwork provides a strong and durable structure for casting the concrete panels and can withstand the high pressures exerted by the wet concrete during the curing process. Additionally, steel formwork allows for precise and accurate shaping of the wall panels, ensuring they meet the desired specifications and dimensions. The steel frame formwork system can be easily assembled and disassembled, making it convenient for repetitive use in mass production of precast wall panels. Overall, steel frame formwork offers numerous advantages for the production of precast wall panels, such as strength, durability, accuracy, and ease of use.

- Q: What are the different types of supports used in steel frame formwork systems?

- There are several types of supports used in steel frame formwork systems, including adjustable props, scaffolding, and horizontal and vertical beams. These supports help to provide stability and ensure proper alignment and positioning of the formwork during construction.

- Q: How does steel frame formwork address issues of concrete shrinkage and expansion?

- The construction technique known as steel frame formwork effectively solves the problems of concrete shrinkage and expansion. One reason for this is steel's high tensile strength, which allows it to withstand the forces exerted by concrete during the shrinkage and expansion process. As a result, the concrete structure remains undamaged and free from cracks. Furthermore, steel frame formwork offers a rigid and stable framework for pouring concrete. This ensures that the concrete is evenly distributed and properly supported, minimizing the risk of uneven shrinkage or expansion. The steel frame also acts as a barrier, preventing the concrete from expanding beyond its intended dimensions. In addition, steel frame formwork allows for the use of expansion joints. These joints are strategically placed within the formwork to accommodate the natural movements of the concrete caused by temperature changes and moisture variations. By incorporating these expansion joints, the steel frame formwork enables the concrete to shrink and expand without causing any structural issues or damage. Moreover, steel frame formwork can be easily adjusted and modified to accommodate changes in concrete dimensions due to shrinkage or expansion. This flexibility allows for necessary adjustments to be made during the construction process, ensuring a precise and accurate final product. In summary, steel frame formwork effectively addresses the issues of concrete shrinkage and expansion by providing a strong and stable framework, incorporating expansion joints, and allowing for easy adjustments. By utilizing this construction technique, the concrete structure remains intact and unharmed by these natural processes.

- Q: How does steel frame formwork handle concrete shrinkage and expansion?

- Steel frame formwork is designed to handle concrete shrinkage and expansion by providing the necessary flexibility and strength to accommodate these movements. Concrete shrinkage occurs as the water in the concrete mix evaporates, causing the material to contract. Steel frame formwork accounts for this shrinkage by using adjustable mechanisms that allow for slight movements and adjustments in the formwork. These mechanisms, such as telescopic struts or adjustable props, can be easily adjusted to compensate for the shrinkage and maintain the desired form and shape of the concrete structure. On the other hand, concrete expansion can occur due to various factors such as temperature changes or moisture absorption. Steel frame formwork is designed to withstand these expansion forces without compromising the integrity of the structure. The steel frames are rigid and provide the necessary strength and support to resist the expansion forces exerted by the concrete. Furthermore, steel frame formwork can also incorporate expansion joints, which are flexible connections between different sections of the formwork. These joints allow for controlled movement and expansion of the concrete, minimizing the risk of cracks or damage. Overall, steel frame formwork is specifically designed to handle concrete shrinkage and expansion by providing flexibility, adjustability, and strength. This ensures that the formwork remains stable and secure during the curing process, ultimately resulting in a structurally sound and durable concrete structure.

- Q: The main beam is the beam that is connected to both ends of the beam In the main frame, the cross beam of the vertical and horizontal cross, why should it be connected at the intersection?Do you need a connection plate for welding? Directly to the steel repair, plug welding can not?

- Two can be, anyway, there is a connection plate, the intensity can be guaranteed, it depends on the construction requirements and requirements of the demolition.

Send your message to us

Steel Frame Formwork for Column Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords