120 Type Steel Frame Formwork for Column Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 120 Steel frame formwork-column formwork

With adjustable flexiable sizes of frame, the column steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean with column formwork. As the framework, it is adapted to the plywood with thickness of 18mm. High-precision production line guarantees the perfect products.

2. Main Features of 120 Steel frame formwork-Column formwork

◆ Allowable pressure is 80KN/m2 .

◆ Faster and easy operation.

◆ The dimension for column is adjustable.

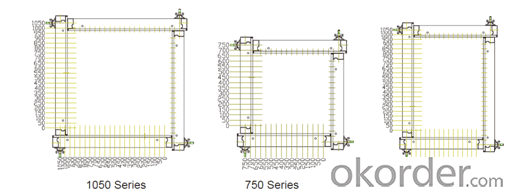

3. 120 Steel frame formwork-column formwork Images

4. 120 Steel frame formwork-Column Formwork Specifications

1050 Series /750 Series Adjustable Column Formwork

5. FAQ of 120 Steel frame formwork-column formwork

1) What can we do for you?

.We can ensure the quality of the120 Steel frame formwork-column formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of early prop head formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: When the span of the main girder in steel frame is large, it is necessary to arrange the secondary beam

- The floor of the steel frame, the spacing of the secondary beam to the structure of the board material

- Q: Can steel frame formwork be used in combination with lightweight concrete mixes?

- Combining steel frame formwork with lightweight concrete mixes is indeed possible. Steel frame formwork is a highly adaptable and long-lasting solution for concrete construction, capable of accommodating a variety of concrete mixes, including lightweight options. Typically, lightweight concrete mixes incorporate lightweight aggregates, such as expanded clay, shale, or pumice, which decrease the overall weight of the concrete without compromising its strength or durability. During the pouring and curing process, steel frame formwork serves as the essential support and structure, effectively securing the lightweight concrete mix in place. This combination enables the creation of structures that are lighter and more efficient, while still meeting the necessary strength and stability requirements. Nonetheless, it is crucial to adhere to the manufacturer's guidelines and specifications for both the steel frame formwork and the lightweight concrete mix to ensure proper compatibility and optimal performance.

- Q: Can steel frame formwork be used for both heavy and lightweight concrete structures?

- Yes, steel frame formwork can be used for both heavy and lightweight concrete structures. Steel frame formwork is a versatile and durable solution that can accommodate different types of concrete structures. It provides the necessary support and stability during the pouring and curing process, regardless of the weight of the concrete. The strength and rigidity of steel make it suitable for heavy concrete structures, while its flexibility and adaptability allow it to be used for lightweight concrete structures as well. Additionally, steel frame formwork can be easily adjusted and reused, making it a cost-effective option for various construction projects.

- Q: How does steel frame formwork contribute to the strength and stability of a concrete structure?

- Steel frame formwork is a crucial component in the construction of concrete structures as it plays a significant role in enhancing their strength and stability. Firstly, the use of steel frame formwork provides a rigid and robust structure that ensures the concrete is poured and supported accurately. This formwork system is constructed using steel frames, which offer high load-bearing capacity and excellent resistance to deformation or bending. As a result, it effectively prevents any potential movement or displacement of the concrete during the pouring and curing process, ensuring the structural integrity of the final product. Moreover, steel frame formwork allows for precise alignment and positioning of the concrete elements. The frames can be easily adjusted and aligned according to the desired shape and dimensions of the structure, ensuring accurate placement of the concrete. This precision is of utmost importance as any misalignment or unevenness can compromise the structural integrity and stability of the concrete structure. Steel frame formwork enables the construction team to achieve the desired shape, size, and levelness of the concrete elements, leading to a stronger and more stable structure. Furthermore, steel frame formwork contributes to the overall stability of the concrete structure by providing lateral support. The frames are securely braced and connected, creating a rigid framework that resists any lateral forces, such as wind or seismic loads. This additional stability ensures that the structure remains intact and can withstand external forces, thereby enhancing its overall strength and durability. In addition to strength and stability, steel frame formwork also offers several other benefits. It is reusable, allowing for cost-effective construction projects, as the formwork can be dismantled and used for multiple concrete pours. The steel frames are durable and resistant to corrosion, ensuring their longevity and reliability. Moreover, the versatility of steel frame formwork allows for the construction of various shapes and sizes, accommodating different architectural designs and structural requirements. In conclusion, steel frame formwork greatly contributes to the strength and stability of a concrete structure by providing a rigid and precise framework, ensuring accurate alignment and positioning, and offering additional lateral support. Its use enhances the structural integrity, durability, and overall performance of the concrete structure, making it a vital component in the construction industry.

- Q: What is the average lifespan of a steel frame formwork system?

- The average lifespan of a steel frame formwork system can vary depending on various factors such as the quality of materials, maintenance, and frequency of use. However, with proper care and maintenance, a well-built steel frame formwork system can last anywhere from 10 to 20 years or even more.

- Q: Can steel frame formwork be used for tall structures?

- Yes, steel frame formwork can be used for tall structures. Steel frame formwork is known for its strength and durability, making it suitable for constructing tall buildings. Its rigid structure allows for precise and efficient concrete pouring, ensuring the stability and integrity of the structure. Additionally, steel frame formwork can be easily adjusted and reused, making it a cost-effective solution for tall construction projects.

- Q: Can steel frame formwork be used for post-tensioned slabs or beams?

- Yes, steel frame formwork can be used for post-tensioned slabs or beams. Steel frame formwork is a versatile and durable system that can accommodate various construction techniques, including post-tensioning. The steel frame provides the necessary strength and stability to support the post-tensioning process, which involves tensioning steel cables or rods within the concrete structure to increase its load-bearing capacity. When using steel frame formwork for post-tensioned slabs or beams, it is important to ensure proper design and construction techniques are followed. The formwork system should be able to withstand the additional forces exerted during the post-tensioning process, such as the tensioning forces and anchorages. The formwork should also allow for the proper placement and alignment of the post-tensioning elements, such as ducts or sleeves, that will house the tensioning cables or rods. Additionally, the steel frame formwork should be designed to accommodate the necessary access points for the installation and stressing of the post-tensioning system. This may involve incorporating removable panels or openings in the formwork to allow for the insertion and tensioning of the post-tensioning elements. Overall, steel frame formwork can be effectively used for post-tensioned slabs or beams, provided that the design and construction considerations specific to post-tensioning are taken into account. This ensures the successful integration of the post-tensioning system with the formwork, resulting in a structurally sound and efficient concrete structure.

- Q: How is a steel frame formwork system assembled and disassembled?

- A steel frame formwork system is assembled by connecting prefabricated steel frames together in the desired configuration. The frames are then secured in place using clamps or pins. Once the concrete is poured and set, the system is disassembled by removing the clamps or pins and dismantling the steel frames, allowing for easy removal of the formwork.

- Q: How does steel frame formwork handle the movement and settlement of a structure?

- Steel frame formwork is a construction technique that uses steel frames to support the concrete during the pouring and curing process. One of the main advantages of using steel frame formwork is its ability to handle the movement and settlement of a structure. Steel has high tensile strength, which means it can withstand the forces caused by movement and settlement without deforming or failing. This is crucial in construction, as buildings are subject to various types of movement and settlement over time. Firstly, steel frame formwork provides a rigid structure that supports the weight of the concrete and distributes it evenly across the foundation. This helps to minimize any uneven settlement or movement that may occur. Additionally, steel frame formwork is designed to be flexible and adjustable. It can accommodate slight variations in the structure's dimensions, allowing for some movement without compromising its integrity. This flexibility is particularly important in areas with high seismic activity, where structures need to be able to withstand earthquakes and other ground movements. Moreover, steel frame formwork is often equipped with expansion joints. These joints allow the structure to expand and contract naturally without causing any damage. Expansion joints are crucial in areas with extreme temperature fluctuations, as they prevent the steel and concrete from cracking due to thermal expansion. In summary, steel frame formwork handles the movement and settlement of a structure by providing a strong and flexible support system. Its high tensile strength, adjustability, and inclusion of expansion joints make it ideal for withstanding the forces and movements that a building may experience throughout its lifespan.

- Q: How does steel frame formwork contribute to better dimensional accuracy in precast elements?

- Steel frame formwork contributes to better dimensional accuracy in precast elements by providing a rigid and stable structure that ensures precise alignment and positioning of the concrete during the casting process. The steel frame acts as a strong support system, preventing any deformation or movement that could result in inaccuracies or variations in the final dimensions of the precast elements. Additionally, the steel formwork allows for easy adjustments and fine-tuning, enabling precise control over the shape, size, and overall dimensional accuracy of the precast elements.

Send your message to us

120 Type Steel Frame Formwork for Column Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords