Adjustable Aluminum Formwork For Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Custom SF63 Rectangle / Square

Column / Wall Construction

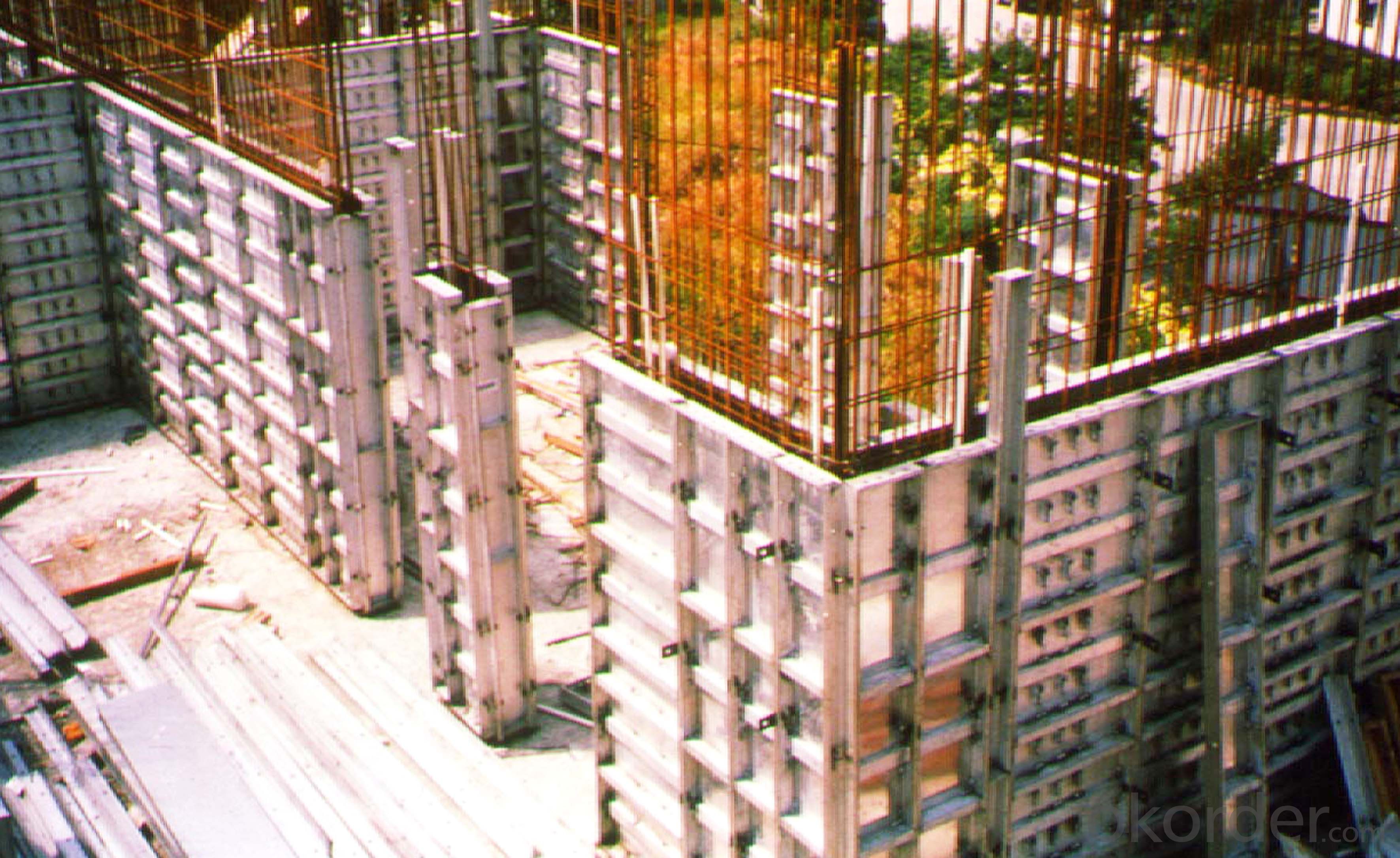

Adjustable Aluminum Formwork For Rectangle / Square Concrete Column

Description:

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

Competitive Advantage:

1. Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2. Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4. It is with the advantages of standard design, excellent applicability and interchangeable.

5. Simple, safe and fast.

6. No rust corrosion, easy maintenance, and high turnover rate.

Applications:

- Q:What are the different types of formwork hinges used with steel frame formwork systems?

- There are two main types of formwork hinges used with steel frame formwork systems: fixed hinges and adjustable hinges. Fixed hinges are used when the desired formwork angle does not need to be changed, providing a stable and rigid connection between formwork panels. On the other hand, adjustable hinges allow for flexibility in adjusting the formwork angle, making them suitable for projects with varying concrete structures. These hinges offer ease of use and versatility in formwork installation and removal.

- Q:What are the common quality control measures for steel frame formwork systems?

- There are several common quality control measures for steel frame formwork systems in the construction industry. These measures are implemented to ensure the integrity, strength, and safety of the formwork system during the concrete pouring process. Some of the common quality control measures include: 1. Material Inspection: The quality control process starts with a thorough inspection of the steel frame formwork system's materials. This includes checking the quality and specifications of the steel used for the frame, beams, and other components. Additionally, the inspection also focuses on the welding quality, surface finish, and overall structural strength of the steel components. 2. Dimensional Accuracy: It is crucial to ensure that the steel frame formwork system is manufactured with precise dimensions and tolerances. This involves verifying the accuracy of measurements, angles, and alignments of the formwork system components. Any discrepancies can lead to misalignment and compromise the integrity of the structure. 3. Load Testing: Load testing is performed to evaluate the load-bearing capacity and overall stability of the steel frame formwork system. This involves subjecting the formwork system to simulated loads that it will experience during the actual construction process. The system is carefully monitored to ensure it can withstand the expected loads without failure or deformation. 4. Safety Inspections: Safety is a critical aspect of quality control in steel frame formwork systems. Regular inspections are conducted to ensure that all safety features, such as handrails, guardrails, and access points, are properly installed and functioning correctly. Additionally, the inspection also verifies that the formwork system complies with industry safety standards and regulations. 5. Documentation and Record Keeping: Proper documentation and record keeping are essential for quality control in steel frame formwork systems. This includes maintaining records of material certifications, inspection reports, load testing results, and safety compliance documents. These records provide a comprehensive history of the formwork system's quality and help ensure traceability and accountability. 6. Inspection of Formwork Joints: The joints between different formwork components, such as beams and frames, need to be inspected for proper alignment and integrity. This involves checking for any gaps, misalignments, or loose connections that could compromise the stability and strength of the formwork system. By implementing these quality control measures, construction companies can ensure that steel frame formwork systems are manufactured and installed to the highest standards. This helps minimize the risk of structural failures, enhances worker safety, and ensures the successful completion of construction projects.

- Q:Can steel frame formwork be used for both residential and commercial construction?

- Steel frame formwork is a valuable choice for both residential and commercial construction. This versatile and enduring solution is suitable for a range of construction projects, including residential and commercial buildings. It possesses remarkable strength and stability, enabling it to withstand the pressure and weight of concrete during pouring and curing. Moreover, steel frame formwork is both adjustable and reusable, offering a cost-effective option for small-scale residential projects and large-scale commercial developments alike. Its adaptability allows for the construction of diverse shapes and sizes, meeting the demands of various architectural designs. In summary, steel frame formwork is a dependable choice for both residential and commercial construction ventures.

- Q:How does the cost of steel frame formwork compare to other types of formwork?

- The cost of steel frame formwork can vary based on various factors including project size and complexity, location, and market conditions. Generally, steel frame formwork tends to be more expensive compared to other formwork types. One reason for the higher cost is the material itself. Steel is a durable and strong material, making it ideal for supporting heavy loads and enduring harsh conditions. However, its strength and durability come at a higher price compared to materials like wood or plastic, commonly used in other formwork types. Moreover, skilled labor and specialized equipment are often necessary for the installation and removal of steel frame formwork. This increases the overall cost as it may require more time and resources compared to other formwork systems that are easier to handle and require less expertise. Despite the higher initial cost, steel frame formwork offers several advantages that can make it a cost-effective choice in certain situations. The durability and reusability of steel formwork can result in long-term savings as it can be used for multiple projects, reducing the need for frequent replacements. Furthermore, steel formwork provides excellent quality and precision, leading to smoother finishes and decreasing the need for additional labor or materials for finishing work. Ultimately, when considering the cost of steel frame formwork in comparison to other formwork types, it is crucial to assess the benefits it offers in relation to the initial investment. Factors such as project requirements, duration, and long-term use can impact the cost-effectiveness of steel frame formwork in different construction scenarios.

- Q:Can steel frame formwork be used in combination with other types of formwork systems?

- Indeed, steel frame formwork has the capability to be utilized alongside various other formwork systems. This particular formwork system offers a robust and long-lasting framework for concrete placement, enabling the creation of diverse shapes and sizes. It can be employed in conjunction with different formwork systems, such as timber formwork, aluminum formwork, or plastic formwork, in order to enhance the efficiency and versatility of the construction process. By amalgamating different formwork systems, construction experts can capitalize on the distinctive features provided by each individual system. For instance, steel frame formwork offers exceptional load-bearing capacity and stability, which makes it suitable for large-scale projects or structures with intricate geometries. Conversely, timber formwork may prove to be more economical and manageable for smaller projects or when a specific surface finish is desired. The amalgamation of steel frame formwork with other formwork systems grants greater flexibility and adaptability in construction projects. This allows contractors to customize the formwork design according to the specific requirements of each section of the structure, thus optimizing resource utilization and reducing construction time. However, when utilizing a combination of formwork systems, it is imperative to ensure compatibility and proper integration between the various components. This can be achieved through meticulous planning, coordination, and supervision, guaranteeing the stability and safety of the formwork structure. To conclude, steel frame formwork can effectively be employed in conjunction with other types of formwork systems, affording construction professionals a wider array of options to meet the specific needs of each project.

- Q:Can steel frame formwork be used for the construction of swimming pools?

- Yes, steel frame formwork can be used for the construction of swimming pools. Steel frame formwork is a popular choice for constructing swimming pools due to its durability, strength, and ability to withstand the pressure of concrete pouring. It provides a strong and stable structure that can handle the weight of the concrete and water in the pool. Additionally, steel frame formwork can be easily customized and adjusted to create different pool shapes and sizes. It is also reusable, which makes it a cost-effective option for pool construction projects. Overall, steel frame formwork is a suitable choice for the construction of swimming pools.

- Q:Can steel frame formwork be used in earthquake-prone areas?

- Indeed, steel frame formwork proves to be a viable option for regions susceptible to earthquakes. Renowned for its durability and strength, steel becomes an ideal choice in constructing buildings within seismic-prone areas. By providing a rigid structure, steel frame formwork effectively withstands the powerful forces generated during an earthquake, guaranteeing the safety and stability of the edifice. Furthermore, the convenience of assembling and disassembling steel formwork enables swift and efficient construction, a significant advantage in earthquake-prone locations where time is of utmost importance. Nevertheless, adhering to the relevant building codes and regulations specific to the area remains crucial to ensure the proper design and installation of the steel frame formwork system.

- Q:How is steel frame formwork assembled and disassembled?

- Steel frame formwork is a versatile and durable system used in construction projects to create concrete structures such as columns, walls, and slabs. Assembling and disassembling steel frame formwork involves a series of steps that ensure accuracy, efficiency, and safety. To assemble steel frame formwork, the following steps are typically followed: 1. Preparation: Before starting the assembly, it is important to ensure that the construction site is clean, level, and free from any debris. This helps in providing a stable base for the formwork. 2. Layout and marking: The layout and dimensions of the concrete structure are marked on the ground using chalk lines or other suitable marking tools. This step ensures the correct placement of the steel frame formwork. 3. Aligning and leveling: The steel frames are positioned and aligned according to the marked lines. The frames are then leveled using leveling screws or wedges to ensure a uniform and accurate formwork structure. 4. Connecting the frames: Once the frames are aligned and leveled, they are connected using steel pins or clamps. This provides stability and prevents any movement during the concrete pouring process. 5. Placing the plywood panels: Plywood panels are then fixed onto the steel frames using screws or clips. These panels act as a barrier to hold the concrete in place and provide a smooth finish to the structure. To disassemble steel frame formwork, the following steps are typically followed: 1. Removal of plywood panels: The first step in disassembling the formwork is to remove the plywood panels. This can be done by unscrewing the screws or unclipping the clips that hold the panels in place. 2. Disconnecting the frames: Once the plywood panels are removed, the steel frames can be disconnected. This is done by removing the steel pins or releasing the clamps that hold the frames together. 3. Dismantling the frames: After disconnecting the frames, they can be dismantled by unscrewing or unbolting the frame components. It is important to follow the manufacturer's instructions to ensure safe and efficient dismantling. 4. Cleaning and storage: Once the steel frame formwork is disassembled, it is important to clean and inspect the components for any damage or wear. The components are then stacked and stored in a safe and organized manner for future use. Overall, assembling and disassembling steel frame formwork requires careful planning, precise alignment, and adherence to safety guidelines. Following the correct procedures ensures a successful construction process and allows for reusability of the formwork components.

- Q:What are the different types of supports used with steel frame formwork?

- Construction projects utilize various types of supports in conjunction with steel frame formwork. These supports play a crucial role in establishing stability and facilitating the formwork system's ability to bear the weight and pressure generated by the poured concrete. 1. One type of support, known as adjustable steel props, consists of vertical supports that can be modified to different heights using threaded rods. These props are commonly employed alongside steel frames to reinforce horizontal beams or slabs. 2. Another support option is steel shoring systems, which encompass vertical steel tubes equipped with adjustable steel beams or U-heads at their upper ends. These systems are utilized to bolster large slabs or beams during construction. 3. Scaffolding can also serve as supports for steel frame formwork. It furnishes a stable working platform for workers and can be effortlessly adjusted to varying heights. 4. Timber or plywood bracing is sometimes employed to provide supplementary support to steel frame formwork. These bracings are placed diagonally or horizontally between the steel frames to enhance stability. 5. Hydraulic jacks are another resource that can furnish temporary support to steel frame formwork. These jacks are adjustable and can be used to elevate or lower the formwork as required. It is important to note that the selection of supports hinges upon the specific requirements of the construction project, encompassing factors such as the structure's size and shape, the weight of the poured concrete, and the height of the formwork system. The design and installation of these supports should be entrusted to experienced professionals to ensure safety and structural integrity.

- Q:Are there any specific considerations for using steel frame formwork in coastal areas?

- Yes, there are several specific considerations that need to be taken into account when using steel frame formwork in coastal areas: 1. Corrosion resistance: Coastal areas are prone to high levels of humidity, saltwater exposure, and corrosive environments. Therefore, it is crucial to use steel frames that have high corrosion resistance, such as galvanized or stainless steel. This will ensure the longevity and durability of the formwork system. 2. Material selection: The choice of materials for formwork should be carefully considered for coastal areas. It is important to select materials that can withstand the harsh coastal environment, including saltwater, wind, and sand. Steel frames are a suitable choice due to their strength and resistance to corrosion. 3. Maintenance: Regular maintenance is essential to prevent corrosion and ensure the longevity of steel frame formwork in coastal areas. This includes routine inspections, cleaning, and reapplication of protective coatings as necessary. Proper maintenance will help to extend the lifespan of the formwork system and prevent any potential safety hazards. 4. Anchoring and stability: Coastal areas often experience strong winds and storms, which can put additional loads and stresses on the formwork system. It is crucial to ensure that the steel frames are properly anchored and secured to withstand these forces. Additionally, the formwork system should be designed to have adequate stability and resistance against lateral loads, such as wind or wave action. 5. Environmental considerations: Coastal areas are often environmentally sensitive, with ecosystems that need to be protected. When using steel frame formwork, it is important to consider the impact on the surrounding environment. Measures should be taken to prevent any potential pollution or contamination during the construction process, such as using environmentally friendly coatings or sealants. Overall, while steel frame formwork can be used in coastal areas, it is essential to consider the specific challenges posed by the coastal environment. By selecting the right materials, implementing proper maintenance practices, ensuring stability and anchoring, and considering environmental factors, steel frame formwork can be effectively used in coastal construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Aluminum Formwork For Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords