Steel Frame Formwork with Adustable Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

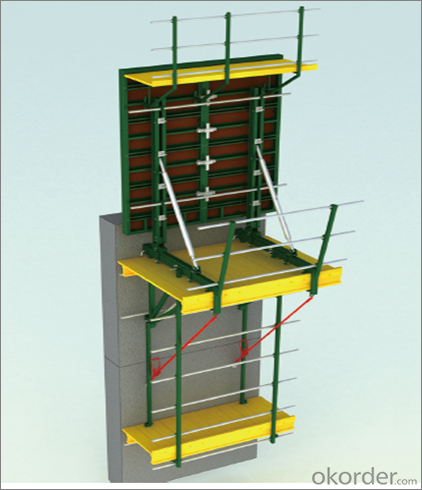

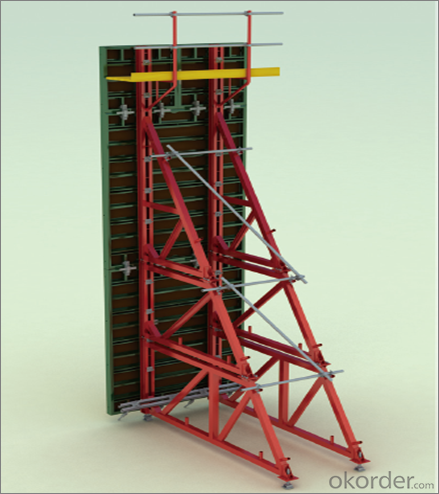

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Is the bamboo plywood and wood plywood the same?

- Bamboo plywood and wood plywood is not the same. Mainly different substrate

- Q: What are the different types of formwork bracing used with steel frame formwork?

- There are several types of formwork bracing commonly used with steel frame formwork, including diagonal bracing, horizontal bracing, and vertical bracing. Diagonal bracing is used to provide stability and resist lateral forces by connecting the vertical members of the formwork system. Horizontal bracing is used to prevent the horizontal movement of the formwork system and maintain its shape. Vertical bracing is used to support the vertical members of the formwork system and ensure their stability during concrete pouring. All these types of bracing play a crucial role in maintaining the integrity and safety of the steel frame formwork structure.

- Q: Can steel frame formwork be used for both small and large-sized concrete elements?

- Yes, steel frame formwork can be used for both small and large-sized concrete elements. Steel frame formwork is a versatile and robust system that is suitable for various construction projects. It can be easily adjusted and customized to accommodate different sizes and shapes of concrete elements. The use of steel frame formwork ensures high-quality and precise construction, allowing for efficient and cost-effective building processes. Additionally, steel frame formwork offers durability and reusability, making it an ideal choice for both small and large-scale projects.

- Q: Can steel frame formwork be used for both plain and reinforced concrete structures?

- Yes, steel frame formwork can be used for both plain and reinforced concrete structures. Steel frame formwork is a versatile and durable formwork system that can be used for various types of concrete structures. It provides a strong and stable framework that can withstand the pressure exerted by both plain and reinforced concrete during the pouring and curing process. The steel frame formwork can be easily adjusted and customized to accommodate different shapes and sizes of structures, making it suitable for use in various construction projects. Additionally, steel frame formwork offers good dimensional accuracy, ensuring that the concrete structure is built according to the required specifications. Overall, steel frame formwork is a reliable and efficient solution for constructing both plain and reinforced concrete structures.

- Q: Can steel frame formwork be used for both above-ground and underground construction?

- Yes, steel frame formwork can be used for both above-ground and underground construction. Steel frame formwork is a versatile and durable system that can be used in various construction applications. Its strength and rigidity make it suitable for above-ground structures such as buildings, bridges, and high-rise structures. Additionally, its resistance to moisture and durability against harsh underground conditions make it a viable option for underground construction, such as tunnels, basements, and underground parking structures. Steel frame formwork provides the necessary support and stability required for both above-ground and underground construction projects, making it a popular choice in the construction industry.

- Q: What are the safety measures that need to be taken while using steel frame formwork?

- To ensure the safety of workers and the success of construction projects, it is crucial to implement various safety measures when utilizing steel frame formwork. These measures encompass: 1. Comprehensive training and supervision: Workers must undergo thorough training on the proper utilization of steel frame formwork, including safe assembly, dismantling, and handling. Additionally, experienced personnel should provide supervision to prevent potential accidents. 2. Regular inspection and maintenance: Consistent inspections are necessary to identify any defects, damages, or signs of wear and tear in the steel frame formwork. Faulty or damaged components should be promptly replaced or repaired. Maintenance efforts should also be undertaken to maintain optimal equipment condition. 3. Utilization of personal protective equipment (PPE): Workers should be equipped with suitable PPE, such as safety helmets, goggles, gloves, and steel-toe boots. This protective gear effectively safeguards against hazards like falling objects or injuries during assembly and dismantling. 4. Ensuring secure footing and fall protection: Workers must be provided with secure footing while working on steel frame formwork structures. Appropriate scaffolding or platforms should be available, and the installation of guardrails is essential to prevent falls from elevated positions. Safety harnesses and lanyards should also be utilized when working at heights. 5. Proper lifting techniques: Workers should be trained in proper lifting techniques to prevent strains or musculoskeletal injuries when handling heavy components of the steel frame formwork. Whenever possible, mechanical aids like cranes or hoists should be utilized to minimize manual lifting. 6. Adequate lighting and ventilation: The work area should be well-lit to ensure optimal visibility, and proper ventilation must be provided to prevent the accumulation of harmful fumes or gases. 7. Effective communication and coordination: Clear communication and coordination between workers and supervisors are vital for smooth operations and accident prevention. Precise instructions, signals, and warning signs should be used to alert workers of potential hazards or changes in the work environment. By adhering to these safety measures, the risk of accidents and injuries associated with steel frame formwork can be significantly reduced, fostering a safer working environment for all parties involved.

- Q: How does steel frame formwork handle concrete curing in humid conditions?

- Steel frame formwork is highly resistant to the effects of humid conditions during concrete curing. The steel material does not absorb moisture, preventing any potential damage or warping. Additionally, the tight joints and secure connections of steel frame formwork ensure proper sealing, minimizing the risk of moisture penetration. This allows for effective curing of concrete, resulting in a strong and durable structure even in humid environments.

- Q: Steel frame 5 meters span to the extent of the H beam

- Not that we can give you anything! That is, The loss outweighs the gain! My CAD is out of date, did not buy, you find a friend down like it!

- Q: How does steel frame formwork affect the overall construction schedule?

- The overall construction schedule can be significantly influenced by steel frame formwork. One of the main advantages of steel frame formwork lies in its quick and easy assembly and disassembly. This implies that the formwork can be set up and taken down more swiftly compared to traditional formwork methods like timber or plywood. As a result, the construction time can be reduced. Furthermore, steel frame formwork boasts a high level of accuracy and precision in the construction process. The rigid and sturdy nature of steel ensures that the formwork maintains its shape and position, resulting in consistent and accurate concrete structures. This eliminates the need for rework and adjustments, saving valuable time in the construction schedule. Moreover, steel frame formwork is highly durable and can withstand the pressures and forces exerted during the concrete pouring process. This durability reduces the risk of formwork failure or damage, which could cause delays in construction. Additionally, it allows for multiple reuses of the formwork, further optimizing the construction schedule and reducing costs. Additionally, steel frame formwork can be easily integrated into various construction techniques, such as precast and cast-in-place methods. This flexibility allows for a smooth construction process and seamless integration into different construction phases, resulting in time savings. In conclusion, steel frame formwork positively impacts the overall construction schedule due to its quick assembly and disassembly, accuracy, durability, and compatibility with different construction techniques. These benefits lead to time savings, reduced rework, and improved efficiency, ultimately resulting in a faster completion of the construction project.

- Q: What are the safety certifications required for steel frame formwork?

- The safety certifications required for steel frame formwork typically include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and OHSAS 18001 or ISO 45001 for occupational health and safety management systems. Additionally, certifications such as CE marking, UL listing, or AS/NZS standards compliance may also be necessary depending on the specific country or region.

Send your message to us

Steel Frame Formwork with Adustable Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords