Steel Frame Formworks Used in Different Kinds of Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

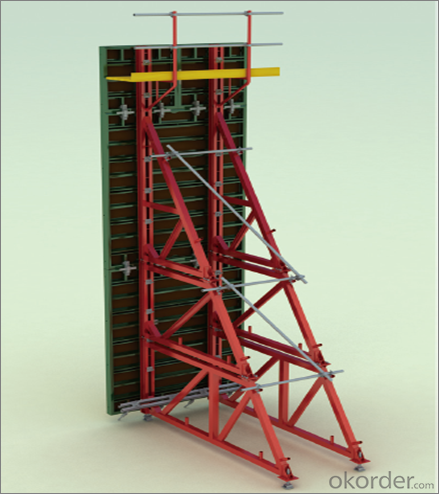

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel frame formwork be used for both reinforced and non-reinforced concrete structures?

- Steel frame formwork is suitable for both reinforced and non-reinforced concrete structures. This versatile system can be easily adjusted and adapted to meet the requirements of different construction projects. It offers a robust and rigid framework for pouring concrete, ensuring the stability and integrity of the structure. Whether there is reinforcement or not, the steel frame formwork can be designed and installed to provide the necessary support and shape for the concrete during construction. It is widely utilized in the construction industry for various projects, such as buildings, bridges, tunnels, and other concrete structures, regardless of their reinforcement status.

- Q: What are the different types of accessories available for steel frame formwork?

- There are several types of accessories available for steel frame formwork, each serving a specific purpose in the construction process. Some of the common accessories include: 1. Wedges: These are used to secure the formwork panels tightly together, ensuring a consistent and sturdy framework. 2. Clamps: Clamps are used to hold the formwork panels in place, preventing any movement during the pouring of concrete. 3. Ties: Ties are used to connect the formwork panels to the structure being built, providing additional stability and support. 4. Brackets: Brackets are used to support the formwork panels at corners or intersections, allowing for a seamless connection between different sections of the formwork. 5. Struts: Struts are used to support the formwork panels vertically, providing additional strength and stability. 6. Anchors: Anchors are used to secure the formwork to the ground or other structures, preventing any movement or displacement. 7. Release agents: Release agents are applied to the formwork to prevent the concrete from sticking to the panels, making it easier to remove the formwork once the concrete has set. 8. Formwork tape: Formwork tape is used to seal the joints between formwork panels, preventing any leakage of concrete during the pouring process. 9. Formwork oil: Formwork oil is applied to the formwork panels to provide a smooth and even surface, ensuring easy removal of the formwork once the concrete is set. 10. Formwork accessories storage: Storage systems are available to organize and store all the formwork accessories efficiently, allowing for easy access and retrieval when needed. These accessories play a crucial role in ensuring the stability, strength, and functionality of the steel frame formwork system, allowing for efficient and safe construction processes.

- Q: Are there any restrictions on the formwork height that can be achieved with steel frame formwork in high-rise structures?

- Yes, there are restrictions on the formwork height that can be achieved with steel frame formwork in high-rise structures. The height of the formwork is limited by various factors such as the load-bearing capacity of the steel frame, the stability of the structure, and the ability to safely and efficiently pour and cure concrete at higher elevations. Additionally, the availability of adequate equipment and skilled labor for formwork installation and removal also plays a role in determining the maximum achievable formwork height in high-rise structures.

- Q: How does steel frame formwork help in reducing construction time?

- By providing a faster and more efficient method of constructing concrete structures, steel frame formwork plays a crucial role in reducing construction time. Firstly, its lightweight and easy-to-handle nature allows for quicker assembly and disassembly compared to traditional formwork systems. This enables the formwork to be easily relocated and reused in different areas of the construction site, saving valuable time. Additionally, steel frame formwork is highly versatile and adaptable, allowing for the construction of complex structures in various shapes, sizes, and configurations. It can be easily adjusted and modified to accommodate changes in design or construction requirements, minimizing the time spent on alterations and adjustments. Furthermore, the use of steel frame formwork ensures a high level of accuracy and precision. The rigid steel frames guarantee consistent dimensions and alignment, resulting in accurate and uniform concrete structures. This eliminates the need for extensive rework and corrections, saving valuable time during the construction process. Moreover, steel frame formwork contributes to faster curing times for concrete. Acting as a heat sink, the steel frames dissipate heat from the concrete, accelerating the curing process. This allows for the faster removal of formwork, facilitating the progression of construction activities. Lastly, steel frame formwork boasts a longer lifespan and can be reused multiple times, reducing the need for frequent replacements. This not only saves construction time but also reduces costs associated with purchasing and disposing of formwork materials. In conclusion, steel frame formwork offers several advantages that significantly reduce construction time. Its ease of handling, versatility, accuracy, faster curing times, and reusability make it the preferred choice for contractors aiming to enhance the efficiency and speed of their construction projects.

- Q: What is the typical lifespan of steel frame formwork accessories?

- The typical lifespan of steel frame formwork accessories can vary depending on various factors such as usage, maintenance, and quality of the materials. However, with proper care and regular maintenance, steel frame formwork accessories can last for many years, often exceeding 10 to 15 years or more.

- Q: How does steel frame formwork contribute to the overall cost of a construction project?

- Steel frame formwork can contribute to the overall cost of a construction project in several ways. Firstly, it may require a higher initial investment compared to other types of formwork, such as timber or aluminum. However, this cost is often justified by its durability and reusability, as steel formwork can withstand multiple uses without significant wear and tear. Additionally, steel formwork can help to expedite the construction process by allowing for faster assembly and disassembly, reducing labor costs. Moreover, its strength and stability can minimize the need for additional support structures, saving on material costs. Overall, while steel frame formwork may have a higher upfront cost, its efficiency and longevity can result in long-term cost savings for the construction project.

- Q: What are the different finishes available for steel frame formwork?

- Some of the different finishes available for steel frame formwork include galvanized finishes, powder-coated finishes, and epoxy finishes.

- Q: What are the different types of concrete curing methods used with steel frame formwork?

- Different concrete curing methods can be used with steel frame formwork to ensure proper hydration and strength development of the concrete, as well as prevent cracking and defects. Some commonly used methods include: 1. Water curing: This traditional method involves continuously moistening the concrete surface with water. It can be done by spraying water directly onto the surface or by covering it with wet burlap or plastic sheets. 2. Membrane curing: Impermeable membranes or curing compounds are applied to the concrete surface to retain moisture and promote hydration. These membranes, made of plastic, wax, or other materials, are usually sprayed or brushed onto the surface. 3. Steam curing: High-pressure steam is used to accelerate the hydration process and achieve faster strength development. This method is commonly used in precast concrete applications where time is crucial. 4. Chemical curing: Chemical compounds like calcium chloride or sodium silicate can be added to the concrete mix to speed up the curing process. These compounds react with the cement to promote hydration and reduce overall curing time. 5. Insulation curing: The concrete surface is covered with insulating materials such as blankets or foam boards to retain heat and moisture. This method is often employed in cold weather conditions to prevent freezing and maintain optimal curing temperature. 6. Carbonation curing: Carbon dioxide (CO2) is used to cure the concrete by injecting it into the mix or applying it to the surface. This triggers a chemical reaction and promotes the formation of calcium carbonate. Carbonation curing is environmentally friendly as it reduces the carbon footprint associated with traditional cement production. It is important to consider project requirements, weather conditions, and time constraints when selecting the appropriate concrete curing method for a steel frame formwork project. Consulting with a structural engineer or concrete specialist is recommended to determine the most suitable method.

- Q: How does steel frame formwork compare to aluminum formwork?

- Steel frame formwork and aluminum formwork are two popular types of formwork systems used in construction projects. While both have their own advantages and disadvantages, they differ significantly in terms of their properties and applications. One major difference between steel frame formwork and aluminum formwork is the material used in their construction. Steel frame formwork is made of steel frames, which provide excellent strength and durability. This makes it suitable for heavy-duty construction projects such as high-rise buildings, bridges, and dams. On the other hand, aluminum formwork is made of lightweight aluminum panels, making it more suitable for low-rise and mid-rise construction projects. Another difference lies in the weight of the formwork system. Steel frame formwork is relatively heavier compared to aluminum formwork. This can be advantageous in certain situations where additional weight is needed to counteract external forces such as wind or seismic loads. However, the weight of steel frame formwork can make it more difficult to handle and transport, requiring more labor and machinery. In terms of versatility, steel frame formwork offers more flexibility in terms of customizability and adaptability. Steel frames can be easily modified or adjusted to accommodate various shapes, sizes, and complex architectural designs. Aluminum formwork, on the other hand, is limited in terms of customization due to its lightweight nature. It is better suited for standard-sized structures or repetitive construction patterns. Cost is also an important factor to consider. Steel frame formwork tends to be more expensive compared to aluminum formwork due to the higher cost of steel and the additional labor required for its handling and installation. However, steel formwork offers a longer lifespan and can be reused multiple times, which can offset the initial investment over the course of multiple projects. Aluminum formwork, although initially cheaper, may need to be replaced more frequently due to wear and tear, making it a more costly option in the long run. Ultimately, the choice between steel frame formwork and aluminum formwork depends on the specific requirements of the construction project. Factors such as project scale, complexity, budget, and desired lifespan should all be considered when selecting the appropriate formwork system. It is advisable to consult with construction professionals and engineers to determine the most suitable formwork system for each unique project.

- Q: How does steel frame formwork handle different types of formwork stripping equipment?

- Steel frame formwork is a versatile and durable system that can handle different types of formwork stripping equipment with ease. The steel frames, which are designed to provide stability and support, can accommodate various stripping tools such as mechanical or hydraulic systems. One of the advantages of steel frame formwork is its ability to withstand the high pressure and force exerted during the stripping process. This is crucial when different types of stripping equipment are used, as they require a strong and sturdy support system to ensure safe and efficient formwork removal. The steel frames are engineered to provide a stable and secure platform for the stripping equipment. They are designed with precision and accuracy to ensure proper alignment and compatibility with different types of stripping tools. This ensures that the stripping equipment can be securely attached to the steel frame formwork, allowing for effective and efficient formwork removal. Furthermore, steel frame formwork is highly adaptable, making it suitable for use with various types of formwork stripping equipment. Whether it is a mechanical stripping system that relies on mechanical force or a hydraulic system that utilizes hydraulic power, the steel frames can accommodate and work seamlessly with these different types of equipment. In conclusion, steel frame formwork is specifically designed to handle different types of formwork stripping equipment. Its strength, stability, and adaptability make it an ideal choice for construction projects that require efficient and safe formwork removal.

Send your message to us

Steel Frame Formworks Used in Different Kinds of Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches