column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

china quick form concrete column formwork

Application

column formwork for concrete forming of square columns

Installation

as easy as film faced plywood, but no need release agent

Dismantling

Handle carefully without violent damage and scratch to ensure more usage in good condition

Cleaning

Just clean by water

Maintenance & Storage

No oil treatment, place the panel flat, away from direct sunlight and water.

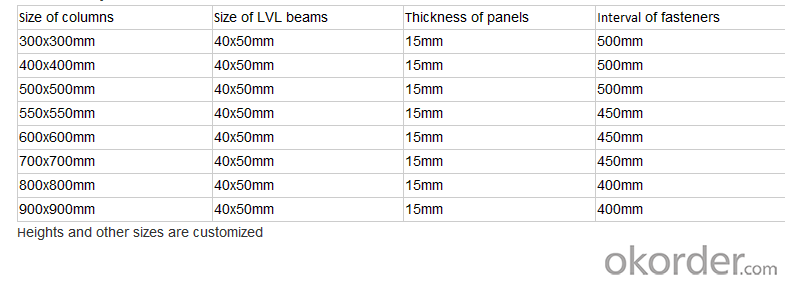

Product options

Advantages

1. reusable 50 times at least

2. quick installation & seamless joining to prevent the leakage of concrete

3. painted accessories, high resistance to rust

4. quick dismantling without concrete release agent

5. nice concrete finish without reworkP

Packing

- Q: Can steel frame formwork be used for both on-site and off-site construction projects?

- Yes, steel frame formwork can be used for both on-site and off-site construction projects. Its versatility and durability make it suitable for various construction applications, allowing it to be easily transported and used in both settings.

- Q: How does steel frame formwork prevent concrete leakage or seepage during pouring?

- Steel frame formwork prevents concrete leakage or seepage during pouring by providing a strong and rigid structure that securely holds the concrete in place. The steel frames are designed to create a tight seal around the edges of the formwork, preventing any escape of the liquid concrete. Additionally, the formwork is properly aligned and braced to ensure that it remains in position and does not shift or deform during the pouring process. This prevents any gaps or openings that could allow the concrete to leak or seep out.

- Q: What are the different types of safety barriers and guardrails used with steel frame formwork?

- To ensure the safety and protection of workers, various safety barriers and guardrails are commonly employed alongside steel frame formwork. These include: 1. Handrails: Horizontal barriers installed along the formwork edges, handrails provide stable support for workers on elevated platforms or scaffolds. They prevent accidental falls and offer a secure grip. 2. Toeboards: Vertical barriers placed on the sides and ends of the formwork, toeboards prevent tools, equipment, or materials from falling off the platform. They safeguard workers below and reduce the risk of accidents. 3. Midrails: Additional horizontal barriers positioned between the handrail and toeboard, midrails create a second barrier to prevent workers from accidentally falling through the gap. 4. Mesh panels: Often used alongside handrails and toeboards, mesh panels are made of durable wire mesh. They secure the sides of the formwork and protect workers from potential hazards by preventing objects from falling off. 5. Safety nets: Installed below the working platform, safety nets act as an additional safety barrier. In the event of an accident, they catch falling objects or workers, minimizing the risk of injury or damage. In summary, these safety measures and guardrails, when properly installed and regularly inspected, establish a secure working environment, prevent falls, and safeguard workers from potential hazards and accidents.

- Q: How much is the glass door with a frame

- The stainless steel frame (304 2.2) toughened glass (6 mm glass) 420 yuan / square meter manual 60

- Q: What are the different finishes that can be achieved with steel frame formwork?

- There are several different finishes that can be achieved with steel frame formwork in construction projects. These finishes are primarily determined by the type of formwork used and the techniques employed during the pouring and curing of the concrete. 1. Smooth Finish: Steel frame formwork can be designed to create a smooth finish on the concrete surface. This is achieved by using high-quality formwork materials, ensuring a tight fit between the formwork panels, and using appropriate release agents to prevent the concrete from sticking to the formwork. A smooth finish is often desired for architectural purposes or when the concrete surface needs to be easily cleaned or painted. 2. Textured Finish: Steel frame formwork can also be used to create various textures on the concrete surface. This can be achieved by using specialized form liners or molds that are attached to the formwork panels. These liners or molds can create patterns, imitate natural materials like wood or stone, or add decorative elements to the concrete surface. Textured finishes are often used in building facades, interior walls, or for aesthetic purposes. 3. Exposed Aggregate Finish: With steel frame formwork, it is possible to achieve an exposed aggregate finish on the concrete surface. This finish is achieved by using form liners or molds that create voids or recesses in the concrete. After the concrete has cured, the formwork is removed, and the surface is treated to expose the aggregates in the concrete mix. Exposed aggregate finishes are often used for sidewalks, driveways, or decorative concrete elements. 4. Stamped Finish: Steel frame formwork can be combined with stamping techniques to create a stamped finish on the concrete surface. This finish is achieved by using specialized stamps or patterns that are pressed into the concrete while it is still in a plastic state. The stamps can create various textures, imitate natural materials, or add decorative elements to the concrete surface. Stamped finishes are commonly used for patios, walkways, or other outdoor areas. In conclusion, steel frame formwork offers a wide range of finishes that can be achieved in concrete construction. These finishes include smooth, textured, exposed aggregate, and stamped finishes, each offering unique aesthetic and functional characteristics. The choice of finish depends on the desired outcome, project requirements, and architectural design considerations.

- Q: The following is a two storey steel frame to be done above the door of the frame of 9 meters high, with the PKPM model is the use of door type rigid frame, with interlayer, or the lower frame, the upper

- Not suitable for separate calculation, it is recommended to use the spatial model analysis. Such as MADIS, 3D3S

- Q: How does steel frame formwork accommodate for different concrete placement methods?

- Steel frame formwork is highly versatile and can accommodate different concrete placement methods due to its adjustable nature. The frames can be easily modified and repositioned to suit various pouring techniques, such as pour-in-place, precast, or tilt-up. Additionally, the steel frames can be adjusted to accommodate different concrete densities and flow rates, ensuring optimal results for each specific placement method.

- Q: Can steel frame formwork be adjusted to accommodate different dimensions?

- Yes, steel frame formwork can be adjusted to accommodate different dimensions. The modular nature of steel frame formwork allows for easy adjustments and reconfiguration to meet varying project requirements and dimensions. This flexibility makes it an ideal choice for construction projects with changing dimensions or complex geometries.

- Q: Can steel frame formwork be used for both horizontal and vertical concrete elements?

- Certainly! Steel frame formwork offers the convenience of being applicable to both horizontal and vertical concrete elements. Its versatility lies in its adaptability, as it can be effortlessly modified and tailored to suit varying shapes and sizes of concrete elements. With its remarkable robustness and stability, it proves to be an ideal choice for horizontal slabs, vertical walls, and columns. Moreover, the durability of steel frame formwork is noteworthy, allowing it to be reused multiple times, thereby presenting a cost-effective alternative for diverse construction endeavors.

- Q: How does steel frame formwork handle the placement of fire-rated barriers and partitions within the concrete structure?

- Steel frame formwork provides a robust and efficient solution for the placement of fire-rated barriers and partitions within a concrete structure. With its strong and durable nature, steel frame formwork ensures the accurate positioning and alignment of these fire-rated elements. The rigid framework allows for precise installation, ensuring that the barriers and partitions are securely embedded within the concrete structure, providing reliable fire protection. Additionally, steel frame formwork allows for easy adjustment and modification when necessary, making it a versatile choice for incorporating fire-rated barriers and partitions into the concrete structure.

Send your message to us

column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords