Doka Formwork Accessories

Doka Formwork Accessories Related Searches

Doka Formwork Used Doka Formwork For Sale Doka Formwork Price List Doka Formwork Usa Doka Formwork Singapore Materials For Formwork Doka Deck Formwork Props Doka Shuttering Material Fabric Formwork Formwork Installation Moving Formwork Doka Shuttering System Conventional Formwork System Kumkang Aluminium Formwork System Meva Formwork Formwork System Gliding Formwork Kumkang Aluminium Formwork Doka Shuttering System Formwork Rough Formwork Green Formwork Column Clamps Formwork Engineered Formwork System Formwork Wall Striking Formwork Gass Formwork Steel Formwork System System Formwork SingaporeDoka Formwork Accessories Supplier & Manufacturer from China

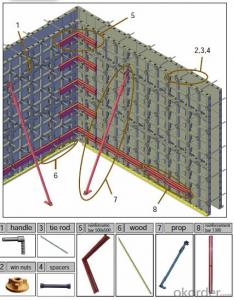

Doka Formwork Accessories are essential components designed to enhance the functionality and efficiency of formwork systems. These accessories include a variety of items such as tie rods, clamps, and formwork beams, which are crucial for the construction of various structures. They are engineered to provide support, stability, and precision during the construction process, ensuring that the formwork system performs optimally and delivers high-quality results.Doka Formwork Accessories are widely used in the construction industry for a multitude of applications, including residential and commercial buildings, bridges, tunnels, and other infrastructure projects. These accessories are designed to work seamlessly with Doka's formwork systems, allowing for quick and easy assembly, as well as efficient dismantling and reconfiguration for different projects. Their versatility and durability make them an indispensable tool for contractors and construction crews, ensuring that they can meet the demands of various construction projects with ease.

Okorder.com is a leading wholesale supplier of Doka Formwork Accessories, boasting a large inventory that caters to the diverse needs of the construction industry. As a reputable supplier, Okorder.com is committed to providing high-quality products at competitive prices, ensuring that customers can access the necessary formwork accessories they need to complete their projects successfully. With a comprehensive range of Doka Formwork Accessories available, Okorder.com is the go-to destination for contractors and construction professionals seeking reliable and efficient solutions for their formwork requirements.

Hot Products