RingLock scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

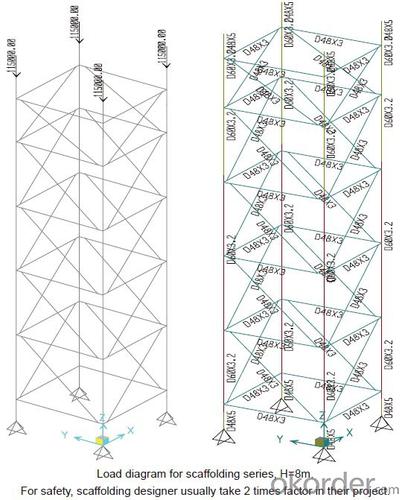

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Are there any specific maintenance requirements for steel formwork systems?

- Yes, there are specific maintenance requirements for steel formwork systems. Steel formwork systems are used in construction to create temporary molds or frameworks for pouring concrete. These systems are designed to be durable and long-lasting, but regular maintenance is necessary to ensure their proper functioning and longevity. One important maintenance requirement for steel formwork systems is to regularly clean and remove any debris or concrete residue from the surfaces. This can be done by using a wire brush or high-pressure water jet to remove any hardened concrete or build-up. Cleaning the formwork prevents the accumulation of materials that can affect the quality and appearance of future concrete pours. Additionally, it is crucial to inspect the steel formwork system for any signs of damage or wear. This includes checking for cracks, dents, or rust on the steel components. If any damage is found, it should be repaired promptly to prevent further deterioration and to maintain the structural integrity of the formwork. Another maintenance requirement is to lubricate the moving parts of the steel formwork system. This includes hinges, locks, and adjustable parts that allow for easy assembly and disassembly. Lubrication helps to prevent corrosion, ensures smooth operation, and prolongs the lifespan of the formwork system. Furthermore, regular inspection of the formwork system's alignment and stability is necessary. This ensures that the formwork remains level and securely in place during concrete pouring. Any misalignment or instability should be addressed immediately to prevent accidents or structural issues during construction. Overall, proactive maintenance of steel formwork systems is essential to ensure their proper functioning, durability, and safety. Regular cleaning, inspection, repair, and lubrication are key to maintaining the quality and longevity of these systems, ultimately contributing to successful construction projects.

- Q: Are all steel plates used for beam slab prefabrication

- If all steel plates are used for precast beam and slab, the shape of prefabricated components should be adopted

- Q: What are the different types of accessories available for steel formwork?

- Steel formwork offers a range of accessories designed to improve the efficiency and effectiveness of the system. Several common types of accessories include: 1. Clamps - These securely connect formwork panels, providing stability and preventing movement during concrete pouring. 2. Wedges - These level and align the panels by inserting them between the panels and tightening for a secure fit. 3. Ties - Made of steel, these secure formwork panels to the structure by inserting them through panel holes and anchoring them. 4. Connectors - These join panels at corners or junctions, maintaining the formwork system's structural integrity. 5. Spacers - These maintain a specific distance between panels, ensuring the desired concrete thickness. 6. Brackets - These support formwork panels during construction, preventing sagging or bending. 7. Release agents - Applied to panels before pouring concrete, these prevent adhesion, allowing for easy removal once the concrete sets. 8. Handles - These facilitate handling and positioning of panels, providing a secure grip for proper placement. 9. Chamfers - These create beveled edges on concrete, attached to panels for a finished look. 10. Accessories for special applications - Specialized accessories exist for curved structures, columns, and beams. These examples highlight the range of accessories available for steel formwork. The choice of accessories depends on project requirements and desired outcomes. Selecting the appropriate accessories is crucial for a successful and efficient formwork system.

- Q: How does steel formwork accommodate for different concrete pouring methods?

- Steel formwork is a versatile construction tool that can accommodate different concrete pouring methods in various ways. Firstly, steel formwork can be easily adjusted and customized to fit different shapes and sizes of concrete structures. This flexibility allows for the creation of unique and intricate designs. Additionally, steel formwork provides a high degree of accuracy and precision during the concrete pouring process. The steel panels are precisely manufactured to specific dimensions, ensuring that the concrete is poured in the right locations and with the desired thickness. This accuracy is crucial for achieving the structural integrity and aesthetic appeal of the final concrete structure. Steel formwork also offers the advantage of being reusable and durable. This means that it can withstand multiple concrete pouring cycles without losing its shape or strength. This reusability not only saves costs but also allows for different concrete pouring methods to be employed over time. For example, steel formwork can be used for traditional pouring methods like gravity pouring, as well as more advanced techniques like slipforming or precast concrete pouring. Moreover, steel formwork can be easily dismantled and moved to different locations, making it suitable for projects that require frequent changes in pouring methods. This adaptability is especially useful in construction projects with multiple phases or when pouring concrete in hard-to-reach areas. In summary, steel formwork accommodates different concrete pouring methods through its adjustable nature, accuracy, durability, and adaptability. It provides the necessary support and stability during the pouring process, ensuring that the concrete structure is built according to the desired specifications and quality standards.

- Q: Can steel formwork withstand extreme weather conditions?

- Yes, steel formwork is designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it highly resistant to harsh weather elements such as heavy rain, strong winds, and high temperatures. Additionally, steel formwork is often treated with protective coatings to further enhance its resistance to corrosion and degradation caused by extreme weather conditions.

- Q: Is steel formwork suitable for projects with high formwork reusability?

- Yes, steel formwork is suitable for projects with high formwork reusability. Steel formwork is known for its durability and strength, which allows it to withstand multiple uses without significant wear and tear. It can be easily assembled and disassembled, making it efficient for reuse on different projects. Additionally, steel formwork provides a smooth and consistent finish to concrete structures, ensuring high-quality results. While the initial cost of steel formwork may be higher compared to other types of formwork, its long lifespan and reusability make it a cost-effective solution for projects requiring frequent formwork reuse.

- Q: How does steel formwork handle construction joints?

- Steel formwork is a versatile and durable option when it comes to managing construction joints. Its design is specifically tailored to meet the demands of construction joints, ensuring a seamless and efficient construction process. To begin with, steel formwork boasts strength and stability, enabling it to withstand the pressure and weight exerted on construction joints. This guarantees that the formwork remains intact and firmly in place, even during the pouring and compacting of concrete at the joints. Furthermore, steel formwork is highly flexible and can be easily adjusted to accommodate different shapes and sizes of construction joints. This allows for precise and accurate placement of the formwork, guaranteeing proper formation and alignment of the joints. Moreover, steel formwork is reusable, making it a cost-effective choice for managing construction joints. Once the concrete has fully cured and the formwork is removed, it can be cleaned, repaired if necessary, and utilized again for future construction projects. This reduces the need for additional formwork materials and minimizes waste. Additionally, steel formwork provides a smooth and uniform surface finish, which is crucial for construction joints. It aids in preventing any leakage or seepage of concrete at the joints, ensuring that the structure remains watertight and structurally sound. In conclusion, steel formwork is an exceptional option for handling construction joints. Its strength, flexibility, reusability, and ability to provide a smooth surface finish make it a dependable and efficient solution for construction projects of varying sizes and complexities.

- Q: How does steel formwork affect the aesthetics of a building?

- The aesthetics of a building can be significantly impacted by steel formwork in various ways. Firstly, steel formwork allows for the creation of complex and intricate designs, resulting in visually appealing architectural elements. The flexibility and strength of steel enable the construction of unique shapes, curves, and patterns that enhance the overall aesthetics of the building. Moreover, steel formwork gives concrete surfaces a smooth and seamless finish. This contributes to a more refined and polished appearance, especially when compared to other formwork materials like timber or plastic. The absence of visible joints, seams, or imperfections on the concrete surfaces enhances the overall look of the building. Additionally, steel formwork offers the advantage of reusability, leading to cost savings and reduced waste. This economic benefit allows architects and designers to allocate more resources to enhance the building's aesthetics, such as incorporating high-end finishes or unique decorative elements. Furthermore, steel formwork ensures a high level of accuracy and precision during the construction process. This precision guarantees that the final structure is aligned and symmetrical, enhancing the overall visual harmony of the building. Straight lines, sharp corners, and consistent dimensions can be achieved with steel formwork, resulting in a visually pleasing and harmonious architectural design. Lastly, the durability and strength of steel formwork contribute to the long-term aesthetics of the building. Steel formwork can withstand harsh weather conditions, resist corrosion, and maintain its structural integrity over time. This durability ensures that the building's aesthetics remain intact for an extended period, enhancing its overall appeal and value. To conclude, steel formwork has a positive impact on the aesthetics of a building by enabling complex designs, providing a smooth finish, allowing for precision and accuracy, offering cost savings, and ensuring long-lasting visual appeal.

- Q: What are the factors to consider when selecting steel formwork?

- When selecting steel formwork, there are several important factors to consider. These include the project requirements, such as the size and complexity of the structure, the desired finish, and the required strength and durability. Other factors include the cost-effectiveness of the formwork system, the ease of assembly and disassembly, and the availability and accessibility of the formwork supplier. Additionally, it is crucial to consider the load-bearing capacity and stability of the steel formwork, as well as its compatibility with other construction materials and techniques.

- Q: Can steel formwork be used for concrete culverts?

- Yes, steel formwork can be used for concrete culverts. Steel formwork is a durable and strong material that can withstand the pressure and weight of the concrete. It provides a smooth surface finish and allows for easy installation and removal. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for constructing concrete culverts.

Send your message to us

RingLock scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords