Ring Lock Scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

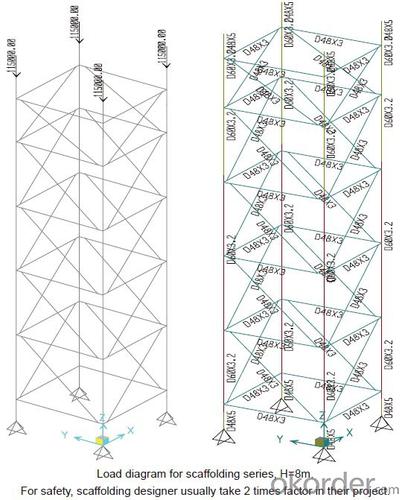

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: What are the common quality control measures for steel formwork systems?

- Steel formwork systems commonly undergo several quality control measures to ensure their effectiveness and safety in construction projects. These measures include: 1. Visual assessment: A thorough examination of the steel formwork system's condition is conducted to identify any noticeable defects, such as dents, cracks, or deformations. Damaged or compromised components must be promptly repaired or replaced. 2. Measurement and dimensional verification: Ensuring accurate measurements and dimensional alignment of steel formwork components is crucial. This is achieved by utilizing precise measuring tools and equipment to guarantee a proper fit. 3. Inspection of welded joints: Since welded joints are often used to connect various components of steel formwork systems, it is vital to conduct comprehensive inspections to detect any defects, like cracks or incomplete penetration. Non-destructive testing methods, such as visual inspection, ultrasonic testing, or magnetic particle testing, may be employed to evaluate the weld quality. 4. Load testing: To validate the structural integrity and load-bearing capacity, load testing is performed. This procedure involves applying a predetermined load to the system and evaluating its performance under stress. It helps identify any weaknesses or defects that could compromise the formwork's safety and stability. 5. Examination of surface finish: The surface finish of steel formwork systems must be smooth and devoid of roughness or irregularities that could affect the quality of the concrete finish. Inspections are carried out to ensure that the formwork surfaces are adequately cleaned, treated, and coated, if necessary. 6. Documentation and traceability: It is imperative to maintain proper documentation and traceability of the steel formwork system components. This includes keeping records of inspections, repairs, replacements, and other pertinent information. Proper documentation ensures timely and accurate resolution of any issues or concerns that may arise. These quality control measures are indispensable for guaranteeing the durability, safety, and performance of steel formwork systems in construction projects.

- Q: Are there any limitations to the size of concrete pours with steel formwork?

- Steel formwork poses limitations for large concrete pours due to various factors. Firstly, the weight and size of the steel formwork itself can be challenging. Maneuvering heavy and large steel formwork can prove difficult, particularly for sizable pours. Moreover, additional supports and bracing are necessary for larger pours. To prevent bending or collapsing under the concrete's weight, steel formwork often requires reinforcement and bracing. This increases the installation's complexity and cost. Additionally, the size and weight of the concrete become limiting factors. Curing large concrete pours generates substantial heat, potentially causing thermal cracking and durability issues. Steel formwork may not endure the intense temperatures and pressures produced by substantial volumes of concrete, leading to deformation or failure. Furthermore, the logistics and transportation of large concrete pours present challenges. Limited availability of concrete trucks and pumps capable of transporting significant volumes can result in delays and escalated expenses. In summary, steel formwork is suitable for diverse concrete pours, but its usage for larger and complex projects necessitates careful evaluation. Assessing project-specific requirements and constraints is crucial to determine the feasibility and appropriateness of employing steel formwork for sizable concrete pours.

- Q: Concrete, reinforcing steel for the labor price? 18 storey elevator apartment with a layer of underground carpentry, concrete, steel artificial price. (to the workers to do the Contractor) the problem added: steel, including the production and installation of a full set of artificial ha, concrete is mixed business. Template carpenter??? Concrete with nails??? Steel??? Including machine...Is the area of 10000 square meters of construction area template?How many tons of steel?

- Template carpenter according to the template surface calculation, according to 18 yuan /M2 (including nails)Concrete by cubic, according to 20 yuan /M3

- Q: What are the environmental considerations of using steel formwork?

- Several factors must be taken into account when evaluating the environmental impact of steel formwork. First and foremost, the production of steel involves extracting iron ore, which can have adverse effects on the environment. Mining activities can cause deforestation, destroy habitats, and lead to soil erosion. Moreover, the extraction process requires a significant amount of energy, often derived from non-renewable sources, resulting in greenhouse gas emissions. Another aspect to consider is the transportation of steel formwork. Due to its weight, transporting steel from the manufacturing site to the construction site can increase fuel consumption and emissions. This is especially true when the construction site is far from the steel manufacturing facility. However, it is worth noting that steel formwork offers several environmental advantages. Steel is a durable material that can be reused multiple times, minimizing the need for new formwork production. This helps reduce the demand for raw materials and waste generation. Additionally, steel formwork can be easily recycled at the end of its lifespan, further reducing its environmental impact. Furthermore, steel formwork is renowned for its strength and stability, which can lead to more efficient construction processes. This, in turn, can result in reduced construction time and lower energy consumption during the building phase. To mitigate the environmental impact of steel formwork, it is crucial to prioritize sustainable practices throughout its lifecycle. This includes sourcing steel from responsible suppliers who prioritize environmental stewardship, promoting the recycling and reuse of formwork, and optimizing transportation and logistics to minimize carbon emissions. Overall, although there are environmental considerations associated with steel formwork, its durability, reusability, and recyclability make it a viable option for sustainable construction practices when managed responsibly.

- Q: Is steel formwork suitable for all types of construction projects?

- Steel formwork is a versatile and widely used construction material that is suitable for a variety of construction projects. However, it may not be suitable for all types of construction projects. Steel formwork offers several advantages such as durability, reusability, and high load-bearing capacity. It can be used for both large-scale and small-scale projects, including residential, commercial, industrial, and infrastructure projects. Steel formwork is particularly well-suited for projects that require a high degree of precision and quality finish, such as high-rise buildings, bridges, and tunnels. However, there are certain factors to consider when determining the suitability of steel formwork for a specific construction project. One important factor is the project's budget. Steel formwork tends to have a higher initial cost compared to other types of formwork materials such as timber or aluminum. Therefore, it may not be suitable for projects with tight budget constraints. Another factor to consider is the project's timeline. Steel formwork requires skilled labor and time for assembly, disassembly, and transportation. This may result in longer construction periods, which may not be feasible for projects with strict deadlines. The complexity of the project is also an important factor to consider. Steel formwork is highly adaptable and can be custom-made for specific project requirements. However, if the project involves irregular or complex shapes, it may be more challenging and time-consuming to construct steel formwork compared to other types of formwork materials. Additionally, the environmental conditions of the construction site should be taken into account. Steel formwork is durable and can withstand harsh weather conditions. However, it may not be suitable for projects in coastal areas or locations with high humidity, as steel is susceptible to corrosion. In conclusion, while steel formwork is suitable for a wide range of construction projects, its suitability should be evaluated on a case-by-case basis. Considerations such as budget, timeline, complexity of the project, and environmental conditions should be taken into account to determine if steel formwork is the most suitable choice for a specific construction project.

- Q: Can steel formwork be used for precast concrete facades?

- Yes, steel formwork can be used for precast concrete facades. Steel formwork provides a strong and durable framework for pouring and shaping the precast concrete panels that make up the facade. It offers several advantages, including high strength, stability, and the ability to create complex shapes and intricate details. Steel formwork also allows for easy demoulding and reusability, making it a cost-effective solution for producing precast concrete facades. However, it is important to ensure that the steel formwork is properly designed and fabricated to meet the unique requirements of the project and the desired aesthetic of the facade.

- Q: What are the limitations of using steel formwork?

- There are several limitations of using steel formwork in construction projects. Firstly, steel formwork is relatively expensive compared to other types of formwork materials such as wood or aluminum. This can significantly increase construction costs, especially for large-scale projects. Secondly, steel formwork is heavy and requires heavy machinery and equipment for transportation and installation. This can be challenging in areas with limited access or on sites with uneven terrain. Additionally, steel formwork requires skilled labor for proper installation and dismantling. This can create delays and increase labor costs if the workforce is not experienced in working with steel formwork. Moreover, steel formwork is not as flexible as other types of formwork materials. It may not be suitable for complex or irregular shapes, which can limit design possibilities. Another limitation is the potential for corrosion. Steel formwork is vulnerable to rust and corrosion, especially in environments with high moisture or chemical exposure. Regular maintenance and corrosion protection measures are essential to ensure the longevity of steel formwork. Lastly, steel formwork is not as environmentally friendly as other alternatives. Steel production involves significant energy consumption and carbon emissions, which can contribute to environmental degradation. Overall, while steel formwork offers strength and durability, its limitations in terms of cost, weight, flexibility, corrosion susceptibility, and environmental impact should be carefully considered before choosing it for construction projects.

- Q: Can steel formwork be used in areas with limited labor availability?

- Yes, steel formwork can be used in areas with limited labor availability. Steel formwork is a versatile and durable system that requires less labor compared to traditional formwork methods. It is easy to assemble and disassemble, and can be reused multiple times, reducing the need for continuous labor for formwork construction. Additionally, steel formwork is lightweight and can be easily transported to remote areas, making it suitable for construction projects in locations with limited labor resources. Overall, the use of steel formwork can help streamline the construction process and optimize labor usage in areas with limited labor availability.

- Q: Are there any specific considerations for using steel formwork in seismic zones?

- Yes, there are several specific considerations for using steel formwork in seismic zones. Firstly, steel formwork provides better strength and stiffness compared to other formwork materials such as wood or aluminum. This is crucial in seismic zones where the structure needs to withstand the lateral forces generated by an earthquake. The high strength of steel formwork helps in preventing deformation or failure during seismic events. Secondly, steel formwork offers better durability and reusability. In seismic zones, there is a higher likelihood of frequent earthquakes, and the formwork needs to withstand multiple cycles of loading and unloading. Steel formwork is known for its robustness and ability to withstand repeated use, making it suitable for seismic zones where regular formwork replacement may not be feasible. Another consideration is the design of the steel formwork panels. In seismic zones, it is important to ensure that the formwork panels have sufficient stiffness to resist lateral forces. This can be achieved by using thicker steel plates or adding stiffening elements to the formwork structure. Additionally, the joints between formwork panels should be well-designed and properly reinforced to resist the dynamic forces induced by earthquakes. Moreover, the connection between the steel formwork and the supporting structure should be carefully designed. In seismic zones, it is crucial to ensure a strong and rigid connection to prevent the formwork from detaching or collapsing during an earthquake. Adequate reinforcement, proper anchorage, and well-designed joint details are essential to ensure the stability of the formwork system under seismic loads. Lastly, it is important to consider the construction sequence and the timing of formwork removal in seismic zones. The formwork should be designed to provide sufficient lateral support to the concrete during the curing process, as premature removal of formwork can compromise the structural integrity. The formwork removal should be planned carefully to avoid any sudden changes in the load distribution that could potentially affect the seismic performance of the structure. In summary, when using steel formwork in seismic zones, considerations such as strength, durability, design, connection, and construction sequence are important to ensure the safety and stability of the formwork system and the overall structure during seismic events.

- Q: How does steel formwork contribute to improved construction site logistics?

- Steel formwork contributes to improved construction site logistics in several ways. First and foremost, steel formwork is durable and reusable, which reduces the need for frequent replacement and disposal. This leads to significant cost savings and reduces the amount of waste generated on the construction site. Additionally, steel formwork is highly versatile and can be easily customized to meet specific project requirements. This flexibility allows for efficient and precise construction, resulting in improved productivity and reduced construction time. With steel formwork, construction site activities can be streamlined, making it easier to manage and coordinate various tasks. Furthermore, steel formwork provides enhanced safety on construction sites. Its sturdy and rigid structure ensures stability during concrete pouring and curing processes, minimizing the risk of accidents or structural failures. This results in a safer working environment for construction workers and reduces the likelihood of delays or disruptions caused by safety issues. Moreover, steel formwork offers better control over the quality of the concrete structure being built. Its smooth surface and accurate dimensions help achieve consistent and precise finishes. This reduces the need for rework or corrections, saving time and reducing material wastage. Lastly, steel formwork is easy to handle and transport due to its lightweight nature compared to traditional timber formwork. This simplifies logistics planning and allows for faster and more efficient movement of formwork components across the construction site. The ease of handling also reduces the physical strain on workers, leading to increased productivity and reduced risk of injuries. In conclusion, steel formwork contributes to improved construction site logistics by offering durability, versatility, safety, quality control, and ease of handling. These benefits contribute to cost savings, reduced waste, enhanced productivity, and a safer working environment, ultimately leading to more efficient and successful construction projects.

Send your message to us

Ring Lock Scaffolding Accessories for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords