Ring-lock Scaffolding Accessories for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

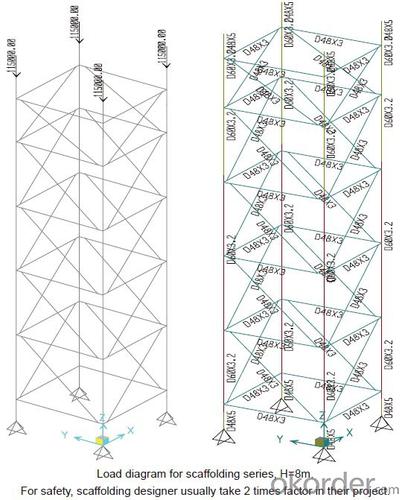

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Is steel formwork reusable?

- Yes, steel formwork is reusable. Steel formwork is a type of temporary mold or structure that is used to hold wet concrete in place until it sets and hardens. Unlike other types of formwork, such as timber or plywood, steel formwork is known for its high durability and strength. The steel panels and frames are designed to withstand the pressure exerted by the wet concrete, ensuring that the formwork remains intact during the pouring and setting process. Due to its robustness, steel formwork can be reused multiple times, making it a cost-effective option for construction projects. After the concrete has set and the formwork is no longer needed, it can be dismantled and cleaned, ready to be used again on future projects. The reusable nature of steel formwork not only reduces waste but also saves money on material costs, as there is no need to continually purchase new formwork for each project. However, it is important to note that the reusability of steel formwork depends on proper maintenance and handling. Regular inspection and maintenance are necessary to ensure that the formwork remains in good condition and free from any defects or damage. Additionally, proper handling during dismantling and transportation is crucial to prevent any bending or distortion of the steel components. In conclusion, steel formwork is indeed reusable, which makes it a sustainable and cost-effective choice for construction projects. Its durability and strength allow it to withstand multiple uses, reducing waste and saving money in the long run.

- Q: Can steel formwork be easily transported to different job sites?

- Yes, steel formwork can be easily transported to different job sites. Steel formwork is durable, lightweight, and can be disassembled and reassembled easily. It can be stacked and transported using trucks or trailers, making it a convenient option for construction projects in different locations.

- Q: Can steel formwork be used for both new construction and renovation projects?

- Absolutely, steel formwork is applicable in both new construction and renovation projects. It boasts remarkable versatility, effortlessly accommodating diverse project demands. With exceptional sturdiness and resilience, it proves suitable for projects of any scale, whether they are minor or massive. Steel formwork serves the purpose of erecting new structures and revamping existing ones alike. Moreover, it presents the added benefit of reusability, effectively diminishing expenses and waste in the long term. Furthermore, steel formwork guarantees meticulous and precise construction, ensuring top-notch outcomes in both fresh construction endeavors and renovation undertakings.

- Q: How is steel formwork different from other types of formwork?

- Steel formwork is different from other types of formwork primarily because it is made of steel, which provides superior durability, strength, and stability. Unlike traditional wooden formwork, steel formwork is reusable, ensuring cost-effectiveness and reduced waste. It is also highly adaptable, allowing for customization and flexibility in construction projects. Additionally, steel formwork offers a smooth surface finish, leading to enhanced quality and aesthetics of the final structure.

- Q: How does steel formwork affect the overall sound insulation of a structure?

- Steel formwork does not directly affect the overall sound insulation of a structure. Sound insulation primarily depends on the quality and thickness of the materials used for walls, floors, and ceilings, as well as the design and construction techniques employed. However, steel formwork can indirectly impact sound insulation if it is not properly installed or if it creates gaps or weak points in the structure, allowing sound to pass through.

- Q: What are the typical lifespan and durability of steel formwork systems?

- The typical lifespan and durability of steel formwork systems can vary depending on several factors, including the quality of the steel used, the maintenance practices applied, and the intensity of usage. Generally, steel formwork systems are known for their exceptional durability and long lifespan. High-quality steel formwork systems, when properly maintained, can last for several decades. They are designed to withstand heavy loads, repetitive use, and exposure to various weather conditions. The durability of steel formwork systems is often enhanced by protective measures such as galvanization or coating to prevent corrosion. These protective measures can significantly extend the lifespan of the formwork systems by preventing rust and other forms of deterioration. However, it is important to note that the lifespan and durability of steel formwork systems can be influenced by factors such as improper handling, inadequate maintenance, or exposure to harsh environments. If the formwork systems are not properly cleaned, stored, or maintained, their lifespan may be reduced. Additionally, the intensity of usage can impact the lifespan of steel formwork systems. If they are subjected to heavy use or excessive stress, their durability may be compromised, leading to a shorter lifespan. In summary, steel formwork systems are renowned for their durability and long lifespan. With proper maintenance and care, high-quality steel formwork systems can last for several decades, providing a reliable and cost-effective solution for concrete construction projects.

- Q: What is the lifespan of steel formwork?

- The lifespan of steel formwork can vary depending on various factors such as the quality of the steel, maintenance practices, and frequency of use. However, with proper care and maintenance, steel formwork can last for many years, potentially even decades.

- Q: Can steel formwork be used for both above-ground and below-ground structures?

- Yes, steel formwork can be used for both above-ground and below-ground structures.

- Q: What are the different types of edge protection systems used in steel formwork?

- There are several types of edge protection systems used in steel formwork, including steel guardrails, toeboards, mesh panels, and safety nets. These systems are designed to prevent workers from falling or objects from being dropped off the edges of the formwork, ensuring a safe working environment.

- Q: How does steel formwork affect the overall construction site waste recycling?

- Steel formwork positively affects the overall construction site waste recycling by reducing the amount of waste generated. Unlike traditional timber formwork, steel formwork is durable and reusable, resulting in less material wastage. It also contributes to the efficient use of resources as it can be easily dismantled and repurposed for future projects, minimizing the need for new materials. This reduces the environmental impact and promotes sustainability in the construction industry.

Send your message to us

Ring-lock Scaffolding Accessories for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords