Steel Frame Corner-Link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

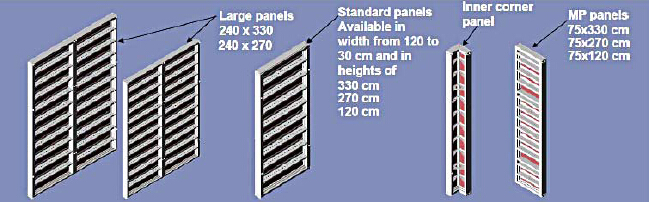

◆ The selection of panels.

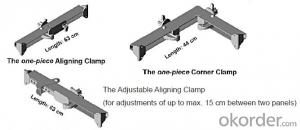

◆ Kinds of panel connectors.

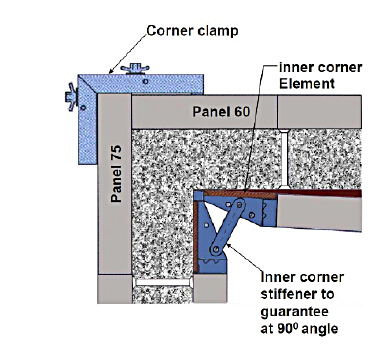

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:Can steel formwork be used in architectural concrete projects?

- Yes, steel formwork can be used in architectural concrete projects. Steel formwork offers several advantages such as durability, reusability, and the ability to create complex shapes and designs. It provides a smooth and consistent finish to the concrete surface, making it suitable for architectural applications where aesthetics are important. Additionally, steel formwork can withstand high pressure and load, allowing for the construction of large and structurally sound concrete elements.

- Q:How does steel formwork contribute to the overall structural integrity of the building?

- Steel formwork contributes to the overall structural integrity of a building in several ways. Firstly, steel formwork provides strong and durable support for the concrete during the construction process. The use of steel ensures that the formwork does not deform or collapse under the weight of the concrete, leading to a more stable and secure structure. Additionally, steel formwork allows for precise and accurate shaping of the concrete, ensuring that the building components are constructed to the required dimensions and specifications. This level of precision is essential for maintaining the structural integrity of the building, as any deviations from the intended design can compromise its stability and safety. Furthermore, steel formwork provides excellent resistance to external forces such as wind, earthquakes, and other environmental loads. The inherent strength and rigidity of steel make it highly resistant to deformation, ensuring that the formwork can withstand these forces without compromising the structural integrity of the building. Moreover, steel formwork is resistant to moisture and other corrosive elements, which can significantly impact the durability and longevity of the structure. By using steel formwork, the risk of deterioration and structural damage due to moisture, rust, or other corrosive agents is minimized, thereby enhancing the overall structural integrity of the building. Lastly, steel formwork allows for efficient construction processes, reducing the time and labor required for building construction. This efficiency not only ensures cost-effectiveness but also minimizes the potential for errors and defects during the construction, thereby further enhancing the structural integrity of the building. In conclusion, steel formwork plays a crucial role in contributing to the overall structural integrity of a building. Its strength, durability, precision, resistance to external forces and corrosion, as well as its contribution to efficient construction processes, all combine to ensure a safe, stable, and long-lasting structure.

- Q:Can steel formwork be used for curved or irregularly shaped structures?

- Yes, steel formwork can be used for curved or irregularly shaped structures. Steel formwork is highly flexible and can be easily customized to match the desired shape or form of the structure. Its strength and durability make it suitable for various construction projects, including those that involve unique or unconventional designs.

- Q:How does steel formwork handle different concrete shrinkage characteristics?

- Steel formwork is an effective solution to handle different concrete shrinkage characteristics. Its rigid and sturdy nature allows it to withstand the pressure exerted by concrete shrinkage without deforming or cracking. Additionally, steel formwork can be easily adjusted and reinforced to accommodate varying levels of shrinkage, ensuring the structural integrity of the concrete.

- Q:What are the common design considerations for steel formwork in heritage buildings?

- When it comes to the design of steel formwork in heritage buildings, there are various factors that must be taken into account. These considerations aim to maintain the historical and architectural significance of the building while ensuring efficient construction processes. Some of the main design considerations for steel formwork in heritage buildings include the following: 1. Preservation of Historical Value: The primary objective when designing steel formwork for heritage buildings is to preserve and protect the historical elements of the structure. The design must respect the building's original architectural features, materials, and construction methods, while also ensuring that the formwork adequately supports the weight of the concrete during the construction process. 2. Structural Stability: The steel formwork design should provide sufficient support and stability to the structure during the pouring and curing of the concrete. It is crucial to consider the load-bearing capacity of the formwork and ensure that it can withstand the weight of the concrete, reinforcing bars, and construction equipment without causing any damage to the heritage building. 3. Flexibility and Reusability: Since heritage buildings often require restoration or repairs over time, it is essential to design the steel formwork in a way that allows for easy disassembly and reuse. This consideration ensures that the formwork can be removed without causing any harm to the building and can be used again for future construction projects. 4. Aesthetic Considerations: In heritage buildings, maintaining the original architectural aesthetics is of utmost importance. The design of the steel formwork should take into account the visual impact it will have on the structure. This may involve incorporating decorative elements or finishes that match the existing architectural style or using formwork that can be concealed or removed once the concrete is set. 5. Accessibility and Safety: The design of the steel formwork should consider the safety requirements for both construction workers and the general public. It should ensure safe access to different areas of the building during construction and minimize any potential risks or hazards associated with formwork installation and removal. 6. Environmental Considerations: Sustainable design practices should be considered when designing steel formwork for heritage buildings. This may involve using recycled or low-impact materials, minimizing waste generation, and implementing energy-efficient construction techniques. In conclusion, the design considerations for steel formwork in heritage buildings revolve around the preservation of historical value, structural stability, flexibility, aesthetics, accessibility, safety, and environmental sustainability. By addressing these factors, architects and engineers can ensure that the construction process respects the heritage value of the building while meeting modern construction standards.

- Q:Can steel formwork be easily transported to different construction sites?

- Yes, steel formwork can be easily transported to different construction sites. Steel formwork is known for its durability and strength, making it suitable for repetitive use and transportation. It can be disassembled, packed, and transported to various locations without much difficulty. Additionally, steel formwork is lightweight compared to other materials like timber, making it easier to handle and move around.

- Q:How does steel formwork affect the overall cost of concrete placement?

- Steel formwork can have a significant impact on the overall cost of concrete placement. While steel formwork may initially have a higher upfront cost compared to other types of formwork, it offers several advantages that can result in cost savings in the long run. Firstly, steel formwork is durable and can be reused multiple times, unlike traditional wooden formwork that often needs to be replaced after a few uses. This reusability reduces the need for purchasing new formwork for each concrete placement, resulting in cost savings over time. Additionally, steel formwork provides a smooth and consistent finish to the concrete surface, reducing the need for extensive surface preparation and finishing work. This can decrease labor costs and save time during the concrete placement process. Furthermore, steel formwork offers better structural stability, ensuring a higher quality concrete placement with minimal defects. This reduces the chances of costly rework or repairs, thereby saving money in the long term. Moreover, steel formwork allows for a faster construction process due to its ease of assembly and disassembly. This can result in reduced labor costs and increased productivity, ultimately leading to lower overall construction expenses. Lastly, steel formwork is highly resistant to moisture and weather conditions, reducing the risk of damage and increasing its lifespan. This durability translates to long-term cost savings as there is no need for frequent replacements or repairs. In conclusion, while steel formwork may have a higher initial investment, its durability, reusability, superior finish, structural stability, construction speed, and resistance to damage make it a cost-effective choice for concrete placement. The long-term savings in labor, materials, and repairs outweigh the initial cost, making steel formwork a wise investment for construction projects.

- Q:Can steel formwork be used for architectural concrete slabs?

- Architectural concrete slabs can indeed utilize steel formwork. When compared to other formwork materials, steel formwork boasts numerous advantages in terms of its strength, durability, and versatility. By providing a rigid structure, it can effectively withstand the pressure exerted by fresh concrete, thereby guaranteeing accurate and precise placement of the slabs. Moreover, steel formwork can be conveniently reused multiple times, rendering it both cost-effective and environmentally friendly. Its smooth surface further contributes to the attainment of high-quality finishes for architectural concrete slabs. Nevertheless, it remains crucial to ensure proper insulation and the use of release agents to prevent heat transfer and potential concrete adherence issues caused by the steel. All in all, steel formwork proves to be a dependable and efficient choice for the creation of architectural concrete slabs.

- Q:How does steel formwork contribute to the overall aesthetics of a structure?

- Steel formwork, a versatile and durable construction material, plays a vital role in shaping a structure's aesthetics. Its impact on a building's visual appeal is evident in various ways. Firstly, steel formwork enables the achievement of precise and intricate designs. The flexibility and strength of steel empower architects and designers to create complex shapes and unique forms that would be difficult or impossible with other materials. This ability to generate innovative and captivating designs enhances a structure's visual appeal, distinguishing it from its surroundings. Furthermore, steel formwork ensures a smooth and flawless concrete surface. The accurate manufacturing of steel panels guarantees a seamless appearance without any gaps or imperfections. This refined finish enhances the overall aesthetics of the structure, providing it with a sleek and contemporary look. Moreover, steel formwork allows for the creation of larger uninterrupted spans and open spaces. The strength of steel enables the construction of thinner and lighter elements, like slabs and beams, without compromising structural integrity. This characteristic grants architects the freedom to design structures with expansive windows, open floor plans, and abundant natural light. These features not only enhance a building's functionality but also contribute to its aesthetic appeal by creating a sense of spaciousness and connection with the environment. Additionally, steel formwork offers the advantage of reusability, significantly reducing construction waste and environmental impact. This sustainability aspect aligns a structure with modern principles of eco-friendly construction, further enhancing its overall aesthetics. The use of steel formwork demonstrates a dedication to sustainable design practices, increasing the perceived value and attractiveness of a building to potential occupants and investors. In conclusion, steel formwork contributes to a structure's aesthetics through its facilitation of intricate designs, provision of a smooth finish, creation of larger open spaces, and support of sustainable construction practices. Its versatility and durability make it an ideal choice for architects and designers seeking visually appealing and distinct structures.

- Q:How does steel formwork affect the overall construction site logistics?

- The overall construction site logistics can be significantly impacted by steel formwork. Firstly, the durability and strength of steel formwork allow for multiple reuses, reducing the need for constant replacement and disposal of materials. This results in reduced waste generation and improved site cleanliness. Moreover, steel formwork is lightweight and easily adjustable, making it easier to handle and transport around the construction site. This improves material handling efficiency and reduces the time required for installation and removal of formwork. Additionally, the lightweight nature of steel formwork reduces the load on the structure, leading to reduced transportation costs and improved safety during construction. Furthermore, steel formwork offers high dimensional accuracy, ensuring precise and consistent shapes for concrete elements. This helps streamline the construction process by reducing the need for excessive adjustments and rework, resulting in improved time management and increased productivity. Additionally, steel formwork provides a smooth and even finish to concrete structures, eliminating the need for additional surface treatments and reducing the time and effort required for finishing work. In summary, steel formwork contributes to improved construction site logistics by reducing waste, enhancing material handling efficiency, improving construction speed, and ensuring high-quality finishes. Its durability, lightweight nature, and dimensional accuracy make it a valuable asset in optimizing construction processes and achieving project timelines more effectively.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Corner-Link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords