Steel-Frame Formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

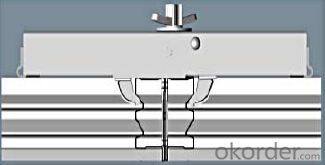

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork affect the structural integrity of a building?

- Steel formwork can greatly enhance the structural integrity of a building. Its rigid and durable nature ensures accurate and consistent placement of concrete, resulting in a stronger and more reliable structure. The use of steel formwork also allows for greater flexibility in design, enabling complex architectural features and reducing the need for additional support elements. Overall, steel formwork plays a crucial role in ensuring that a building maintains its structural stability and meets the required safety standards.

- Q: Can steel formwork be used for both standard and non-standard concrete shapes?

- Indeed, both standard and non-standard concrete shapes can be accommodated by steel formwork. The adaptability of steel as a material enables it to be effortlessly molded and manipulated to produce diverse formwork patterns. Furthermore, its robustness and enduring nature render it appropriate for intricate and intricate concrete shapes. Steel formwork can be tailor-made to satisfy precise project specifications, thus offering flexibility and customization in formwork design. Regardless of whether the desired shape is a conventional rectangle or an exceptional and unconventional design, steel formwork can proficiently be employed to shape and mold concrete structures of various dimensions and configurations.

- Q: Are there any limitations to the size of concrete pours with steel formwork?

- Yes, there are limitations to the size of concrete pours with steel formwork. One limitation is the weight and size of the steel formwork itself. Steel formwork is typically heavy and can be difficult to maneuver, especially in large sizes. This can make it challenging to handle and place the formwork for larger concrete pours. Another limitation is the need for additional supports and bracing for larger pours. Steel formwork may require additional reinforcement and bracing to prevent it from bending or collapsing under the weight of the concrete. This can increase the complexity and cost of the formwork installation. Additionally, the size and weight of the concrete itself can be a limitation. Large concrete pours can generate significant heat during the curing process, which can cause thermal cracking and other durability issues. Steel formwork may not be able to withstand the high temperatures and pressures generated by large concrete volumes, leading to formwork failure or deformation. Furthermore, the logistics and transportation of larger concrete pours can be challenging. The availability of concrete trucks and pumps capable of delivering large volumes of concrete to the construction site can be limited. This can result in delays and increased costs for larger pours. Overall, while steel formwork can be used for a wide range of concrete pours, there are limitations to consider when it comes to the size and complexity of the project. It is important to assess the specific requirements and constraints of each project to determine the feasibility and suitability of using steel formwork for larger concrete pours.

- Q: What is the maximum load that steel formwork can support?

- The maximum load that steel formwork can support depends on various factors such as the thickness and quality of the steel, the structural design and configuration of the formwork, and the supporting structure it is attached to. Generally, steel formwork is designed to withstand heavy loads and is commonly used for high-rise construction projects. However, it is essential to consult the manufacturer's specifications and engineering calculations to determine the specific maximum load capacity for a particular steel formwork system. Additionally, the maximum load capacity can also be influenced by the type of concrete being poured, the duration of the load, and any dynamic forces that may be present during construction. To ensure safety and structural integrity, it is recommended to engage a qualified engineer or structural designer who can assess the specific requirements of the construction project and provide accurate load capacity information for the steel formwork being used.

- Q: Is steel formwork suitable for both residential and commercial construction projects?

- Yes, steel formwork is suitable for both residential and commercial construction projects. It offers durability, strength, and flexibility, making it an ideal choice for various types of construction. Additionally, steel formwork can be easily customized and reused, providing cost-effectiveness for projects of different scales.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork has a reputation for effectively managing concrete bleeding and segregation. Bleeding occurs when water in the concrete mixture rises to the surface, leaving a layer of water on top. Segregation, on the other hand, happens when the solid particles in the concrete mixture separate from the water, causing an uneven distribution. To minimize bleeding and segregation, steel formwork provides a sturdy structure that holds the concrete in place during pouring and curing. The strong construction and tight joints of steel formwork prevent any leaks or seepage, resulting in reduced bleeding. Moreover, steel formwork allows for better control over the placement and compaction of the concrete. The smooth and non-absorbent surface of steel formwork facilitates a uniform distribution of the concrete mixture, minimizing the risk of segregation. Additionally, using steel formwork enables proper vibration and consolidation of the concrete, eliminating any voids or air pockets that could contribute to segregation. Furthermore, steel formwork ensures stability during the curing process, preventing significant movement of the concrete. This stability helps avoid disturbances that could lead to bleeding or segregation. In conclusion, steel formwork is highly effective in managing concrete bleeding and segregation due to its rigid structure, tight joints, smooth surface, and stability. Its use promotes a more consistent and consolidated placement of concrete, resulting in a higher quality finished product.

- Q: How does steel formwork handle different concrete reinforcement spacing?

- Steel formwork is a versatile and robust solution that can easily handle different concrete reinforcement spacing. The formwork itself consists of steel panels or frames that are designed to be adjustable and flexible, allowing for customization according to the specific reinforcement spacing required for a particular concrete structure. Steel formwork panels have various features that make them suitable for accommodating different reinforcement spacing. These panels are typically available in different sizes and shapes, allowing for easy adjustment to fit the desired spacing. Additionally, the panels are usually equipped with adjustable clamps or connectors that enable them to be securely joined together, providing stability and support for the concrete. When it comes to concrete reinforcement spacing, steel formwork can be adapted to meet the specific requirements. The steel panels can be easily positioned and aligned to create the desired spacing for the reinforcement bars. This can be achieved by adjusting the panels horizontally or vertically to accommodate the required distance between the bars. Furthermore, steel formwork provides the necessary strength and durability to withstand the pressure exerted by the concrete during the pouring and curing process. This ensures that the formwork remains intact and stable, even when dealing with different reinforcement spacing. In conclusion, steel formwork is well-equipped to handle different concrete reinforcement spacing. Its adjustable and flexible design allows for customization to fit the specific requirements of each project. The strength and durability of steel formwork ensure that it can effectively support the concrete and maintain its stability throughout the construction process.

- Q: What are the different types of joints used with steel formwork?

- There are several types of joints that are commonly used with steel formwork in construction projects. These joints are designed to ensure stability, strength, and ease of assembly and disassembly. Some of the most commonly used joints include: 1. Butt joint: This is a simple joint where two steel formwork sections are connected by placing their edges together. It is commonly used for straight sections of formwork. 2. Lap joint: In a lap joint, one formwork section overlaps another, creating a strong connection. This joint is often used for longer sections of formwork to provide additional strength. 3. Clamped joint: A clamped joint involves using clamps or bolts to secure the formwork sections together. This type of joint allows for easy adjustment and repositioning of the formwork. 4. Wedge joint: A wedge joint is commonly used to connect vertical and horizontal formwork sections. It involves inserting a wedge-shaped piece into a slot to create a secure connection. 5. Flanged joint: A flanged joint is created by using flanges or plates on the formwork sections that overlap and are bolted together. This joint provides a strong connection and is often used for large and heavy formwork components. 6. Pin joint: A pin joint involves using pins or dowels to connect formwork sections together. This type of joint allows for quick and easy assembly and disassembly of the formwork. It is important to select the appropriate joint type based on the specific requirements of the construction project. The choice of joint will depend on factors such as the formwork design, load-bearing capacity, ease of assembly, and required reusability.

- Q: Can steel formwork be used for precast concrete facades?

- Yes, steel formwork can be used for precast concrete facades. Steel formwork provides a strong and durable framework for pouring and shaping the precast concrete panels that make up the facade. It offers several advantages, including high strength, stability, and the ability to create complex shapes and intricate details. Steel formwork also allows for easy demoulding and reusability, making it a cost-effective solution for producing precast concrete facades. However, it is important to ensure that the steel formwork is properly designed and fabricated to meet the unique requirements of the project and the desired aesthetic of the facade.

- Q: What are the common safety certifications required for steel formwork?

- To ensure the utmost safety on construction sites, steel formwork often necessitates various safety certifications. These certifications encompass the following: 1. OSHA Certification: The steel formwork must possess the Occupational Safety and Health Administration (OSHA) certification. This certification guarantees compliance with OSHA's safety standards, encompassing fall protection, proper scaffolding, and other safety measures. 2. ANSI Certification: Another indispensable requirement is the American National Standards Institute (ANSI) certification for steel formwork. ANSI establishes standards for diverse aspects of construction safety, including materials, equipment, and worker protection. An ANSI certification confirms conformity with these standards. 3. CSA Certification: When employing steel formwork in Canada, the Canadian Standards Association (CSA) certification is usually obligatory. This certification ensures compliance with CSA's safety standards, encompassing design, materials, and structural integrity. 4. CE Marking: The CE marking is an imperative certification for steel formwork employed in the European Union and other countries adhering to European standards. It signifies adherence to the European Union's essential health, safety, and environmental protection requirements. 5. ISO Certification: Although not directly related to safety, an ISO certification signifies that the manufacturer of the steel formwork has implemented a quality management system conforming to the International Organization for Standardization (ISO) standards. This certification guarantees consistent production of the formwork, meeting specific quality requirements. It is crucial to acknowledge that the precise certifications required for steel formwork may vary depending on the country, region, or project specifications. Consequently, consulting local regulations and project specifications is essential to determine the exact certifications necessary for steel formwork in a specific context.

Send your message to us

Steel-Frame Formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords