Adjustable Arced Steel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

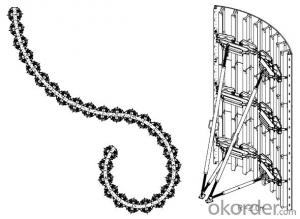

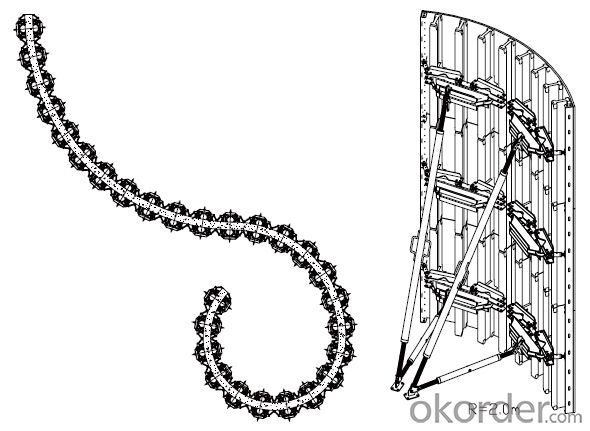

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: What are the common safety precautions when working with steel formwork?

- Some common safety precautions when working with steel formwork include wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toe boots. It is also important to ensure that the formwork is properly secured and braced to prevent collapse or movement. Regular inspections should be conducted to identify any defects or weaknesses in the formwork. Additionally, workers should receive proper training on how to safely assemble, disassemble, and handle the steel formwork to avoid any potential injuries.

- Q: Can steel formwork be reused?

- Indeed, steel formwork has the ability to be reused. It is a material that is both durable and robust, capable of enduring multiple uses. Compared to other formwork materials like timber or plywood, steel formwork boasts a longer lifespan. One of its key advantages lies in its simplicity to dismantle and reassemble. This feature permits the formwork to be used again in different construction projects, thereby reducing the necessity for new materials and resulting in cost savings. Moreover, steel formwork exhibits resistance to weather conditions and moisture, which adds to its longevity. It can handle the pressure exerted by concrete during pouring and curing without any warping or deformation, ensuring a consistent and high-quality outcome. In addition, steel formwork is easily cleaned and maintained, rendering it suitable for reuse. After each use, the formwork can be cleaned and inspected to guarantee its viability for the next project. Any necessary repairs or replacements can be carried out to ensure its structural integrity. To sum up, due to its durability, strength, resistance to weather conditions, and ease of maintenance, steel formwork can be reused. By reusing steel formwork, not only are costs saved, but sustainable construction practices are also fostered by reducing waste and conserving resources.

- Q: How does steel formwork compare to wooden formwork in terms of cost?

- In terms of upfront costs, steel formwork is generally pricier than wooden formwork. This is primarily due to the higher expenses involved in obtaining materials and manufacturing processes for steel formwork. Moreover, the installation of steel formwork often necessitates specialized equipment and skilled labor, which adds to its overall cost. On the contrary, wooden formwork is typically more affordable in terms of initial investment. Wood is readily accessible and relatively inexpensive compared to steel. Additionally, wooden formwork can be easily constructed and customized on-site, reducing the need for additional expenses associated with specialized manufacturing. However, it is crucial to consider the long-term expenses when comparing steel and wooden formwork. Steel formwork has the advantage of being more durable and resistant to wear and tear. It can endure numerous uses and is less prone to damage from moisture, insects, and other environmental factors. As a result, steel formwork can be utilized repeatedly, reducing the need for frequent replacement and decreasing long-term costs. On the other hand, wooden formwork may require regular maintenance, repairs, and eventual replacement due to its vulnerability to damage and deterioration over time. This can lead to supplementary costs over the duration of the project. In conclusion, although steel formwork may initially cost more than wooden formwork, its durability and longevity can result in cost savings in the long run. However, the choice between steel and wooden formwork ultimately relies on the specific project requirements, budget, and other factors such as time constraints and resource availability.

- Q: What are the different types of formwork bracing used in steel formwork?

- There are several types of formwork bracing used in steel formwork, including diagonal braces, horizontal braces, vertical braces, and cross braces. These bracing elements are essential for providing stability and support to the formwork system, ensuring the safe construction of concrete structures.

- Q: What are the common safety certifications for steel formwork?

- There are several common safety certifications for steel formwork used in construction projects. These certifications ensure that the steel formwork meets specific safety standards and regulations. One of the most well-known certifications is the OSHA (Occupational Safety and Health Administration) certification. This certification ensures that the steel formwork complies with the safety regulations set forth by OSHA. It covers various aspects such as stability, load-bearing capacity, and structural integrity. Another widely recognized certification is the ANSI (American National Standards Institute) certification. ANSI provides standards for construction equipment and materials, including steel formwork. This certification ensures that the formwork meets the necessary safety requirements, including strength, durability, and stability. The European standard EN 12812 is also an important certification for steel formwork used in Europe. It sets out the requirements for formwork systems and verifies their safety and performance. This certification covers aspects such as load-bearing capacity, stability, and safety factors. Additionally, the International Organization for Standardization (ISO) provides certifications related to steel formwork safety. The ISO 9001 certification ensures that the manufacturer has a quality management system in place, while the ISO 45001 certification focuses on occupational health and safety management systems. Other specific certifications may be required depending on the country or region. For example, in the United Kingdom, the British Standards Institution (BSI) certification may be necessary. Overall, these safety certifications for steel formwork provide assurance to construction professionals that the formwork they are using meets the necessary safety standards and regulations. It is essential to ensure that the steel formwork used on construction sites holds these certifications to prevent accidents, ensure worker safety, and maintain the structural integrity of the formwork.

- Q: Can steel formwork be used in areas with high seismic vulnerability?

- Yes, steel formwork can be used in areas with high seismic vulnerability. Steel is a strong and durable material that can withstand the forces and vibrations caused by earthquakes. It provides stability and structural integrity to the formwork system, making it suitable for use in seismic-prone regions. Additionally, steel formwork can be designed and reinforced to meet the specific requirements and regulations of the area, ensuring its suitability for use in high seismic vulnerability zones.

- Q: Can steel formwork be used for both regular and irregular concrete structures?

- Yes, steel formwork can be used for both regular and irregular concrete structures. Steel formwork is highly versatile and can be easily adjusted or modified to suit the specific shape and design requirements of any concrete structure, whether it is regular or irregular in shape. Its strength, durability, and flexibility make it the preferred choice for various construction projects.

- Q: How does steel formwork affect the overall construction site dust control?

- Steel formwork can have a positive impact on overall construction site dust control. Compared to other types of formwork, such as wooden or plastic, steel formwork is more durable and less likely to wear down or break, which can generate dust particles. This means that there will be less dust generated during the construction process. Additionally, steel formwork is typically designed to fit tightly together, reducing the gaps and spaces where dust can accumulate. This results in a cleaner and more controlled construction site environment, as there will be fewer areas for dust to settle and become airborne. Furthermore, steel formwork can be reused multiple times, which reduces the need for frequent replacements. This minimizes the amount of waste generated, including dust-producing debris from formwork removal and replacement. Overall, the use of steel formwork contributes to better dust control on construction sites, promoting a safer and healthier work environment for workers and reducing the potential negative impacts of dust on nearby communities and the environment.

- Q: How does steel formwork affect the concrete curing process?

- Steel formwork can significantly impact the concrete curing process by providing a stable and sturdy framework for the concrete to be poured into. The use of steel formwork helps to ensure accurate dimensions and shapes, resulting in a smoother and more precise finish. Additionally, the steel formwork helps to retain moisture within the concrete, promoting better hydration and curing. The smooth surface of the steel formwork also reduces the likelihood of surface defects or imperfections in the cured concrete. Overall, steel formwork plays a crucial role in facilitating a more efficient and effective concrete curing process.

- Q: What is the weight of steel formwork?

- The weight of steel formwork may differ based on several factors, including the steel panels' dimensions and thickness, the supports' type and arrangement, and any extra reinforcements or attachments. Typically, steel formwork panels can weigh between 20 and 40 kilograms per square meter. Nevertheless, it is crucial to acknowledge that these numbers are approximate and might vary depending on the precise design and specifications of the steel formwork employed.

Send your message to us

Adjustable Arced Steel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords