Steel-frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

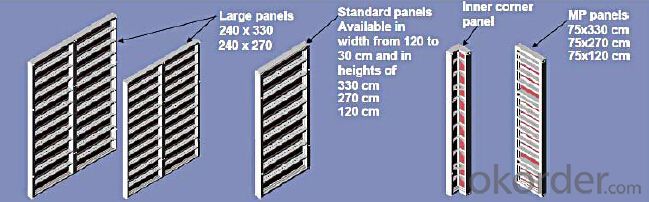

◆ The selection of panels.

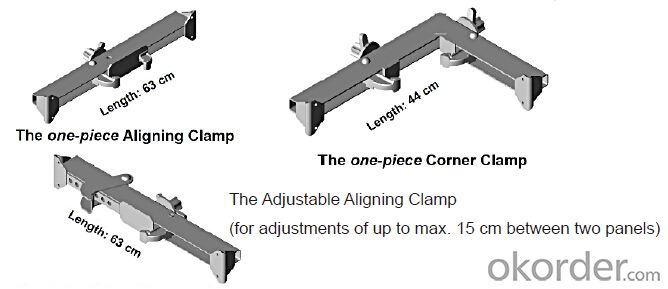

◆ Kinds of panel connectors.

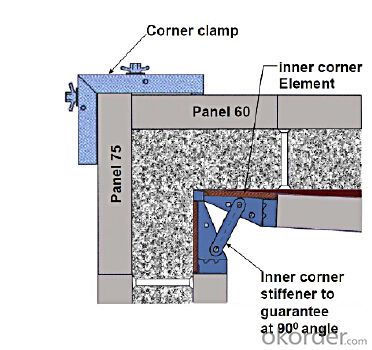

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the different finishes available for steel formwork?

- Some of the different finishes available for steel formwork include smooth, textured, brushed, and galvanized finishes. Each finish serves a specific purpose and can be chosen based on the desired appearance, durability, and functionality of the steel formwork.

- Q: How does steel formwork contribute to the overall stability of the structure?

- There are several ways in which steel formwork contributes to the overall stability of a structure. Firstly, steel is a highly durable and strong material, enabling it to withstand significant loads and pressures. This strength ensures that the formwork remains intact and stable throughout the construction process, even when exposed to heavy loads such as wet concrete. Furthermore, steel formwork offers excellent dimensional stability, unlike materials like wood that may warp or deform over time. This ensures that the structure retains its desired shape and dimensions, which is crucial for stability. Any deformation or movement in the formwork could lead to inaccuracies or weaknesses in the final construction. In addition, steel formwork provides a high level of rigidity and stiffness. This rigidity prevents unwanted movement or shifting of the formwork during concrete pouring and curing, ensuring that the structure adheres to the intended design and specifications. It also evenly distributes weight and forces, reducing the risk of structural failures. Moreover, steel formwork provides exceptional support and reinforcement for the concrete. The steel panels and beams used in formwork act as a framework, holding the concrete in place until it hardens and gains its own strength. This support guarantees the proper formation of the structure and prevents concrete cracking or failure, further enhancing overall stability. Lastly, steel formwork is incredibly adaptable and can be easily customized to fit various architectural designs and construction requirements. This flexibility allows for the creation of complex and unique structures while maintaining stability and strength. In conclusion, steel formwork significantly contributes to the overall stability of a structure through its durability, dimensional stability, rigidity, support, and adaptability. Its robustness, ability to withstand heavy loads, and capability to maintain shape and provide structural support make it a vital component in ensuring the stability and integrity of any construction project.

- Q: Can steel formwork be used in sports facility construction projects?

- Yes, steel formwork can be used in sports facility construction projects. Steel formwork is a versatile and durable option that offers several advantages. Firstly, it provides a high level of strength and stability, making it suitable for large-scale structures like sports facilities. Steel formwork can withstand heavy loads and pressures, ensuring the integrity and safety of the construction. Additionally, steel formwork is highly reusable, which can significantly reduce construction costs and waste. It can be easily dismantled, cleaned, and reassembled for future projects, making it a sustainable choice for sports facility construction. Moreover, steel formwork allows for precise and accurate construction. Its rigidity and dimensional stability ensure that the desired shape and dimensions of the sports facility are achieved. This is particularly important in sports facilities where precise measurements and uniformity are crucial for proper functionality. Furthermore, steel formwork provides a smooth and uniform surface finish. This is essential in sports facilities where the playing surface needs to be even and consistent to ensure fair gameplay and prevent injuries. In summary, steel formwork is a suitable option for sports facility construction projects due to its strength, reusability, precision, and smooth surface finish. It offers numerous benefits and can contribute to the successful completion of sports facilities.

- Q: How does steel formwork impact the overall construction cost?

- Steel formwork is widely favored in the construction industry due to its durability, versatility, and reusability, making it a popular choice. When considering the impact that steel formwork has on the overall construction cost, there are several factors that need to be taken into consideration. To begin with, one of the main advantages of steel formwork is its longer lifespan compared to traditional timber formwork. This means that there is less need for frequent replacements, resulting in cost savings. By spreading the initial investment in steel formwork across multiple construction projects, there is no need for continuous purchases of new formwork materials. Furthermore, steel formwork is known for its superior strength and stability. It can withstand higher concrete pressures, allowing for the construction of taller and more complex structures. This maximizes floor space and enhances the overall efficiency of a project, ultimately reducing construction time and costs. In addition, steel formwork provides a smooth and consistent finish to concrete surfaces, which means that there is less need for additional finishing work. This reduces labor costs and the time required for subsequent trades to begin their work, leading to overall cost savings. Moreover, steel formwork is designed to be easily assembled and disassembled, which facilitates faster construction processes. This efficiency translates into reduced labor costs and shorter project durations, ultimately impacting the overall construction cost. However, it is important to note that the initial investment in steel formwork can be higher compared to other formwork materials such as timber or aluminum. Nevertheless, the long-term benefits and potential cost savings associated with steel formwork outweigh this initial expense. In conclusion, steel formwork has a positive impact on the overall construction cost due to its durability, reusability, and efficiency. Its longer lifespan, strength, and ease of use contribute to cost savings through reduced material replacements, shorter project durations, and minimized finishing work. Despite the higher initial investment, the numerous advantages of steel formwork make it a cost-effective choice for construction projects.

- Q: What are the fire resistance properties of steel formwork?

- Steel formwork is renowned for its exceptional fire resistance. Being a non-combustible material, steel does not burn or contribute to the propagation of fire. Its high melting point confers remarkable resistance to heat and flames. In case of a fire, steel formwork remains intact, ensuring the safety of workers and preventing the fire from spreading to other areas. In addition, steel formwork does not release toxic fumes or smoke when exposed to high temperatures, unlike wood or plastic, which are commonly used in construction. This aspect is crucial as toxic fumes can be harmful and impede evacuation efforts during a fire emergency. Moreover, steel formwork exhibits low thermal conductivity, meaning it does not readily transfer heat. This feature helps confine the heat within the fire zone, curbing its spread to adjacent areas. It also diminishes the risk of structural damage caused by material expansion and contraction due to heat exposure. All in all, the fire-resistant properties of steel formwork render it a dependable choice for construction projects, particularly in locations where fire safety is of utmost importance. Its non-combustible nature, high melting point, absence of toxic fumes, and low thermal conductivity collectively contribute to establishing a secure and safeguarded environment in the face of potential fire hazards.

- Q: Can steel formwork be used for both symmetrical and asymmetrical concrete elements?

- Yes, steel formwork can be used for both symmetrical and asymmetrical concrete elements. Steel formwork is highly versatile and can be customized to meet the specific requirements of any concrete structure, regardless of its shape or complexity. It offers the advantage of being easily adjustable, allowing for the creation of both symmetrical and asymmetrical shapes. Additionally, steel formwork provides excellent strength and durability, ensuring that it can withstand the pressure exerted by the concrete during the pouring and curing process. This makes it a suitable choice for a wide range of concrete elements, including walls, columns, beams, slabs, and more.

- Q: How does steel formwork affect the overall noise transmission in the building?

- Steel formwork can have a positive impact on reducing noise transmission in a building. Its solid and dense structure acts as a barrier, effectively blocking the transmission of sound waves. Additionally, steel formwork is known for its excellent vibration-damping properties, further minimizing noise transmission. Therefore, by using steel formwork, the overall noise levels within the building can be significantly reduced, resulting in a more peaceful and comfortable environment for occupants.

- Q: Can steel formwork be used for structures with high load-bearing requirements?

- Indeed, structures with high load-bearing demands can utilize steel formwork. Renowned for its robustness and resilience, steel proves to be an apt selection for strenuous applications. Steel formwork aptly assists in the construction phase, affording exceptional support and enabling the creation of load-resistant structures. Furthermore, steel formwork guarantees superior dimensional stability, ensuring the structure's endurance and its ability to bear the necessary loads for an extended period. When skillfully reinforced and designed, steel formwork can proficiently tackle the weighty load-bearing prerequisites across diverse construction ventures.

- Q: How does steel formwork affect the concrete pouring process?

- Steel formwork plays a crucial role in the concrete pouring process by providing a sturdy and reliable support structure for the wet concrete. It offers several advantages over other types of formwork, such as timber or plastic. Firstly, steel formwork is highly durable and can withstand the pressure exerted by the wet concrete without warping or deforming. This ensures that the formwork maintains its shape and dimensions, resulting in a finished concrete structure that is accurate and precise. This is particularly important for projects with complex shapes or intricate designs. Additionally, steel formwork is reusable, making it a cost-effective solution for construction projects. Unlike timber or plastic formwork, steel can be used multiple times, reducing the overall project expenses. It also contributes to sustainability by minimizing waste and reducing the environmental impact associated with disposable formwork materials. Another advantage of steel formwork is its ability to provide a smooth surface finish to the concrete. The steel panels are manufactured with high precision, resulting in a uniform and even surface texture on the poured concrete. This is particularly beneficial for projects that require a high-quality finish, such as architectural structures or exposed concrete surfaces. Furthermore, steel formwork offers excellent stability and support during the pouring process. Its rigid structure prevents any movement or shifting of the formwork, ensuring that the concrete is poured accurately and evenly. This is crucial for maintaining the structural integrity of the concrete and preventing any potential defects or weaknesses. In summary, steel formwork significantly affects the concrete pouring process by providing durability, reusability, smooth surface finish, and stability. It ensures that the concrete structure is formed accurately and precisely, resulting in a high-quality finished product.

- Q: Can steel formwork be used in tunnel construction projects?

- Yes, steel formwork can be used in tunnel construction projects. Steel formwork is known for its durability, strength, and ability to withstand high pressure and heavy loads. It can be easily assembled and disassembled, making it suitable for tunnel construction where repetitive use is required. Additionally, steel formwork provides a smooth surface finish and allows for precise shaping and molding of concrete, ensuring the structural integrity of the tunnel.

Send your message to us

Steel-frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords