Construction Specialties Corner Guards

Construction Specialties Corner Guards Related Searches

Safety First Corner Guards Furniture Corner Protectors Corner Guard Wall Protection Glass Corner Protectors 3 Sided Corner Guards Schluter Corner Guards Korogard Corner Guards Stainless Steel Corner Guard Non Adhesive Corner Guards Plastic Wall Corner Protectors Mirror Corner Protectors Cardboard Corner Protectors Couch Corner Protectors Corner Gard Plastic Corner Protectors For Furniture Sofa Corner Protectors Corner Protector Singapore Protective Corners For Tables Laptop Corner Protector Protective Paints Conveyor Belt Idlers Protective Netting Barrier Fence Netting Portable Belt Conveyors Child Proof Corners Tower Crane Hire Overhead Crane Inspection Containment Liners Environmental LinersConstruction Specialties Corner Guards Supplier & Manufacturer from China

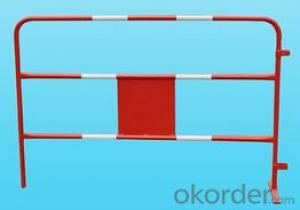

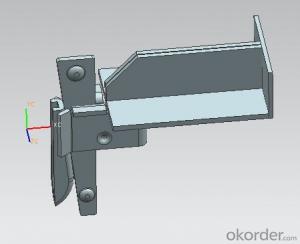

Construction Specialties Corner Guards are a range of protective products designed to shield corners from damage in various environments. These guards are made from durable materials and come in different sizes and shapes to cater to the diverse needs of customers. They are widely used in commercial and residential buildings, schools, hospitals, and other public spaces to prevent damage to walls and corners from accidental impacts or wear and tear. The application of these corner guards extends to various scenarios, such as hallways, stairwells, and room corners, where there is a high risk of damage due to foot traffic and movement of heavy objects.Okorder.com is a leading wholesale supplier of Construction Specialties Corner Guards, boasting a large inventory to meet the demands of various customers. The company prides itself on offering high-quality products at competitive prices, ensuring that clients receive the best value for their investment. By partnering with Okorder.com, customers can benefit from a reliable source of Construction Specialties Corner Guards, ensuring that their facilities are well-protected and maintained.

Hot Products