Ring-Lock Scaffolding Accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

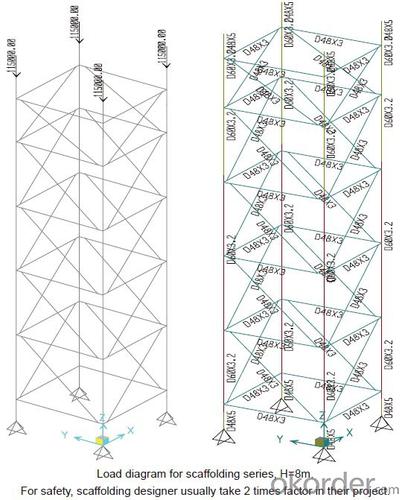

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: What are the common types of connections used in steel formwork systems?

- Steel formwork systems utilize various types of connections, including wedge connections, pin and wedge connections, bolted connections, clamped connections, and magnetic connections. Wedge connections involve employing a wedge-shaped device to firmly secure the panels together. The wedge is inserted into a slot and tightened, creating a dependable and robust connection. Pin and wedge connections entail using pins and wedges to connect the formwork panels. The pins are inserted through panel holes, and the wedges are then driven into the pins, effectively locking them in position. Bolted connections utilize bolts to connect the formwork panels. Pre-drilled holes are present in the panels, and bolts are inserted through these holes and tightened with nuts. This connection method allows for effortless disassembly and reassembly of the formwork system. Clamped connections employ clamps made of steel to connect the formwork panels. These clamps are tightened using bolts or screws, resulting in a secure and rigid joint between the panels. Magnetic connections rely on magnets to connect the formwork panels. Magnetic strips or plates are embedded in the panels, and when the panels are brought close together, the magnets attract and hold them in place. While this connection method is quick and easy, it may not possess the same strength as other connection methods. Each of these connection types offers distinct advantages and disadvantages. The selection of a connection method depends on various factors, including project requirements, ease of assembly and disassembly, as well as the desired strength and stability of the formwork system.

- Q: Can steel formwork be used for underground tunnels?

- Yes, steel formwork can be used for underground tunnels. Steel formwork is a versatile and durable material that is commonly used in construction projects, including underground tunnels. It is able to withstand the pressure and forces exerted by the surrounding soil and rock, making it suitable for use in the construction of tunnels. Additionally, steel formwork is easy to assemble and disassemble, allowing for efficient construction and maintenance of tunnels. Its strength and durability make it a popular choice for underground tunnel construction, providing a reliable and long-lasting solution.

- Q: What are the common challenges faced during steel formwork reassembly?

- During steel formwork reassembly, there are several common challenges that can arise. One of the main challenges is ensuring proper alignment and placement of the formwork components. This includes correctly positioning the steel panels, braces, and connecting rods to ensure they are level and secure. Another challenge is managing the weight and size of the steel formwork components. Steel panels and beams can be heavy and bulky, making it difficult to maneuver and assemble them properly. This requires careful planning and coordination to ensure the safe handling and positioning of these components. Additionally, the complexity of the formwork design can pose challenges during reassembly. Steel formwork systems can be intricate and include various interlocking components and connections. It is crucial to understand the design and assembly instructions to properly reassemble the formwork and ensure its stability and strength. Proper sequencing and timing are also important challenges during steel formwork reassembly. The order in which the formwork components are assembled can impact the overall efficiency and effectiveness of the construction process. It is essential to plan the reassembly carefully and coordinate with other construction activities to avoid delays and ensure smooth progress. Finally, safety is a significant challenge during steel formwork reassembly. Working with heavy steel components can present risks for workers, including the potential for injuries due to falls, lifting accidents, or structural failures. Therefore, it is crucial to have proper safety measures in place, such as using appropriate lifting equipment, providing personal protective equipment, and ensuring workers are trained on safe assembly procedures. Overall, steel formwork reassembly requires careful planning, coordination, and attention to detail to overcome challenges related to alignment, weight, complexity, sequencing, and safety. By addressing these challenges effectively, construction projects can proceed smoothly and efficiently.

- Q: Can steel formwork be used for both reinforced and non-reinforced concrete structures?

- Absolutely! Steel formwork is applicable to both reinforced and non-reinforced concrete structures. This flexible and long-lasting choice can endure the immense pressure generated by the concrete during pouring. Moreover, it can be effortlessly put together and taken apart, making it ideal for diverse construction undertakings. Whether it's a reinforced structure necessitating supplementary reinforcement bar support or a non-reinforced structure requiring a temporary mold, steel formwork proves effective in either scenario. Its robustness and steadiness enable the achievement of accurate shapes and measurements, guaranteeing the desired result for any concrete structure.

- Q: Can steel formwork be used for concrete structures in marine environments?

- Yes, steel formwork can be used for concrete structures in marine environments. Steel is known for its durability and resistance to corrosion, making it suitable for marine applications. Additionally, steel formwork provides a strong and stable support system for pouring and shaping concrete in such environments. However, proper protective measures such as coatings or galvanization should be applied to prevent corrosion and ensure the longevity of the steel formwork.

- Q: What is the process for installing steel formwork?

- Installing steel formwork involves several steps that must be followed meticulously to achieve a successful and sturdy structure. To begin, the site must be prepared by clearing away any debris or obstacles that could hinder the installation process. It is essential to ensure that the ground is level and stable, providing a strong foundation for the formwork. Next, the steel formwork panels are positioned and firmly secured to create the desired shape and structure. This is typically achieved by connecting the panels using various types of connectors like bolts or clamps. Once the panels are securely connected, it is crucial to align and level the formwork accurately. This guarantees the stability and accuracy of the structure being formed. Specialized leveling devices, such as laser levels or spirit levels, can be utilized to ensure precise alignment and a square formwork. After achieving alignment, reinforcement bars (rebars) are placed within the formwork to enhance strength and support for the poured concrete. These rebars are positioned according to the structural drawings and are securely tied together using wire or metal ties. Once the reinforcement is complete, the concrete is poured into the formwork. Great care must be taken to ensure even pouring without any voids or air pockets. Concrete vibrators can be used to eliminate trapped air and ensure proper compaction. Once the concrete is poured, it needs to be appropriately cured to attain the desired strength and durability. This can be accomplished by covering the formwork with a curing compound or by implementing water curing methods, such as spraying water or covering it with wet burlap. Finally, after the concrete has cured, the formwork can be dismantled. This process involves carefully removing the formwork panels, connectors, and supports. The formwork panels can then be cleaned and stored for future use or transported off-site. Overall, the installation of steel formwork necessitates meticulous planning, precise alignment, and flawless execution to achieve a successful and structurally sound end result.

- Q: Can steel formwork be used for both residential and industrial construction projects?

- Yes, steel formwork can be used for both residential and industrial construction projects. Steel formwork is highly versatile and can withstand heavy loads, making it suitable for various construction applications. Its durability and strength make it ideal for use in both residential and industrial settings.

- Q: What are the different types of formwork anchors used in steel formwork?

- There are several types of formwork anchors commonly used in steel formwork, including wedge anchors, sleeve anchors, and through-bolt anchors. Wedge anchors are inserted into pre-drilled holes in the steel formwork and are tightened with a wrench to secure the formwork in place. Sleeve anchors are similar to wedge anchors but have a sleeve that expands against the sides of the hole to provide additional stability. Through-bolt anchors consist of a threaded rod that passes through the formwork and is secured with a nut on the opposite side. These anchors offer a strong and reliable connection for steel formwork.

- Q: What are the factors to consider when selecting steel formwork?

- When selecting steel formwork, there are several factors to consider. 1. Strength and durability: Steel formwork should be strong enough to withstand the weight of the concrete and the forces applied during the pouring and curing process. It should also be able to withstand multiple uses without losing its structural integrity. 2. Flexibility and adaptability: The formwork should be able to be easily adjusted and modified to accommodate different shapes and sizes of concrete elements. This is particularly important in construction projects that involve complex or irregular structures. 3. Ease of assembly and dismantling: The formwork system should be quick and easy to assemble and dismantle, as this can significantly impact the overall construction timeline. The use of standardized components and a simple connection system can contribute to faster assembly and dismantling. 4. Surface finish: The quality of the surface finish of the concrete is important, especially for architectural projects. Steel formwork should provide a smooth and even surface, without any visible marks or imperfections, to ensure a high-quality end result. 5. Cost-effectiveness: The overall cost of the formwork system, including the initial investment, maintenance, and reusability, should be considered. While steel formwork may have a higher upfront cost compared to other materials, its durability and reusability can make it a cost-effective choice in the long run. 6. Safety: The safety of workers during the construction process is paramount. Steel formwork should be designed and manufactured with safety features such as non-slip surfaces, secure connections, and adequate bracing to prevent accidents or collapses. 7. Environmental impact: The environmental impact of the formwork material should also be taken into account. Steel formwork is often considered more environmentally friendly compared to traditional timber formwork due to its reusability and recyclability. By considering these factors, construction professionals can make an informed decision when selecting steel formwork that meets their project requirements and delivers optimal results.

- Q: How does steel formwork handle architectural features such as openings and recesses?

- Steel formwork proves to be an adaptable construction material capable of effectively managing architectural features like openings and recesses. Its strength and flexibility render it perfect for accommodating these design elements in concrete structures. In terms of openings, such as windows or doors, steel formwork can be easily customized to yield precise and well-defined openings. The formwork panels can be cut or shaped to the preferred size and shape, enabling accurate placement of the concrete around the opening. It also provides stability and support during the pouring and curing process, ensuring the structural soundness of the concrete surrounding the opening. On the other hand, recesses can be effortlessly formed using steel panels specifically engineered to create the desired recessed area. These panels can be shaped or molded to match the architectural design, facilitating a seamless integration of recesses into the concrete structure. Steel formwork allows for meticulous control over the depth and dimensions of the recess, guaranteeing compliance with the design requirements. In addition to its adaptability, steel formwork offers several advantages when dealing with architectural features. Its durability and resistance to deformation enable it to withstand the pressure exerted by the concrete, thereby preserving the formwork's shape throughout the construction process. This is crucial in maintaining the accuracy and integrity of architectural features. Moreover, steel formwork is reusable, making it a cost-effective option for projects involving multiple openings and recesses. The panels can be disassembled, cleaned, and reassembled for future use, reducing the need for new formwork materials and minimizing waste. To summarize, steel formwork is a dependable and efficient choice for managing architectural features like openings and recesses. Its strength, flexibility, and reusability make it an ideal construction material for creating precise and visually appealing architectural designs.

Send your message to us

Ring-Lock Scaffolding Accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords