Ring-lock Scaffolding accessories for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

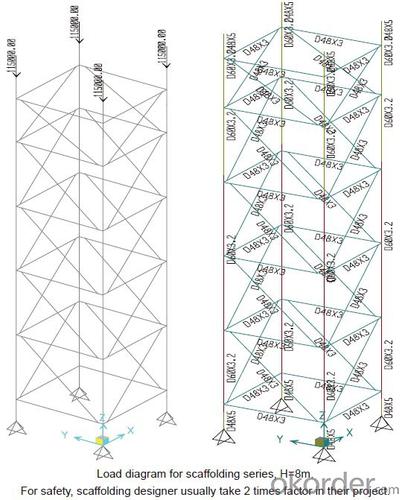

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Can steel formwork be used for both straight and curved walls?

- Steel formwork is versatile and can be utilized for both straight and curved walls. With its exceptional strength and durability, it is ideal for shaping walls of diverse sizes and shapes. Its flexibility allows for effortless adjustments and customization, enabling the creation of both straight and curved walls. The precision and accuracy offered by the steel formwork system ensures that the walls are constructed to the desired specifications. Moreover, the reusability of steel formwork makes it a cost-effective option for projects involving both straight and curved walls.

- Q: Are there any specific quality control measures for steel formwork installation?

- Yes, steel formwork installation has specific quality control measures in place to guarantee correct installation and adherence to required standards. Before installation, one key quality control measure involves inspecting the steel formwork for damages, defects, or deviations from specifications. Any issues discovered during the inspection must be addressed and resolved before proceeding with installation. Verifying the dimensions and alignment of the steel formwork is another quality control measure. This ensures that the formwork is fabricated accurately and aligned properly with the structure. Inaccurate dimensions or misalignment can cause issues during concrete pouring and impact the final structure's quality. Furthermore, quality control measures include checking the stability and strength of the steel formwork. This involves confirming that the formwork is adequately braced and supported to withstand the concrete's pressure. It's crucial to ensure that the formwork can bear the load without deforming or failing. Moreover, closely monitoring the installation process itself is essential to ensure compliance with required procedures and standards. This includes verifying that the formwork is securely fastened and all connections are properly made. Any deviations from installation procedures should be promptly addressed and corrected. Regular inspections and audits should be conducted throughout the installation process to track progress and identify potential issues. This allows for timely interventions and corrections, ensuring that the steel formwork installation meets required quality standards. In conclusion, specific quality control measures are crucial for steel formwork installation to ensure the structure's integrity and safety. By implementing these measures, potential issues or defects can be identified and resolved early on, minimizing the risk of expensive rework or structural failures.

- Q: What are the different material handling requirements for steel formwork?

- Steel formwork offers numerous advantages in construction projects, such as its durability, reusability, and ability to withstand high pressure and loads. However, it is important to consider specific material handling requirements associated with steel formwork. Firstly, when handling and transporting steel formwork panels, it is crucial to use suitable lifting equipment like cranes or forklifts. This ensures that the load is evenly distributed and reduces the risk of dropping or damaging the panels during transportation. Secondly, proper storage is essential to prevent rust and corrosion. The panels should be stored in a dry and well-ventilated area. Additionally, they should be stacked evenly to avoid deformation. It is important to stack them in a way that allows easy access to individual panels without causing damage to others. Regular cleaning and maintenance are necessary to ensure the longevity and reusability of steel formwork. After each use, the formwork should be cleaned to remove any concrete residue, dirt, or debris. Additionally, it is important to inspect the formwork for any signs of damage, such as cracks or bends, and repair or replace them as needed. Skilled workers are required for the proper assembly and disassembly of steel formwork. The panels need to be accurately aligned and securely connected to form a watertight structure. During disassembly, care should be taken to avoid damaging the panels, ensuring they can be reused in the future. To enhance the durability and lifespan of steel formwork, surface protection measures should be taken. This includes applying anti-corrosion coatings or paint to prevent rust and corrosion. Regular inspections should be conducted to identify any signs of damage or deterioration on the surface, and necessary actions should be taken to maintain the integrity of the formwork. In conclusion, adhering to the material handling requirements for steel formwork, such as proper handling and transportation methods, appropriate storage and stacking, regular cleaning and maintenance, skilled assembly and disassembly, and surface protection measures, is essential for optimal performance and longevity in construction projects.

- Q: How do steel formwork systems differ from one another?

- There are several ways in which steel formwork systems can vary from one another. Firstly, their design and construction can be different. Certain systems are modular and consist of pre-assembled panels that can be easily connected and adjusted to create various shapes and sizes. On the other hand, there are custom-made systems that are specifically tailored for particular projects, offering more flexibility in formwork design. Secondly, the strength and durability of steel formwork systems can differ. Some systems are engineered to withstand heavy loads and extreme conditions, making them suitable for large-scale construction projects. Conversely, there are lighter and more portable systems that are better suited for smaller projects or areas with limited access. Another aspect that sets steel formwork systems apart is their user-friendliness. Some systems are designed to be easy to use, with built-in handles, adjustable brackets, and user-friendly locking mechanisms. These features allow for quick and efficient installation and dismantling, saving time and effort on the construction site. Furthermore, steel formwork systems can offer different finishing options. Some provide smooth and precise finishes, which are ideal for projects that require a high-quality surface. Others have textured or patterned finishes, adding a decorative element to the concrete structure. Lastly, steel formwork systems can vary in terms of their cost and availability. Some systems are more affordable and readily available, making them a popular choice for smaller projects or contractors on a tight budget. On the other hand, there are systems that are more expensive or require longer lead times for fabrication, but offer advanced features or customization options. In conclusion, the distinctions between steel formwork systems lie in their design, strength, ease of use, finishing options, and cost. Contractors and construction professionals should carefully assess these factors to choose the most suitable steel formwork system for their specific project requirements.

- Q: What are the different types of formwork connectors used in steel formwork?

- There are several different types of formwork connectors used in steel formwork, including wedge clamps, wedge bolts, pin and wedge systems, and snap ties. These connectors are essential for securely joining formwork panels together and ensuring the stability and strength of the formwork structure.

- Q: What are the typical sizes and dimensions of steel formwork panels?

- The typical sizes and dimensions of steel formwork panels vary depending on the specific project requirements and construction practices. However, common sizes range from 1.2 meters to 2.4 meters in width and 1.8 meters to 3 meters in height. The thickness of these panels typically ranges from 12 millimeters to 18 millimeters. It's important to note that these dimensions can be customized and adjusted according to the specific needs and design of the construction project.

- Q: What are the common connection methods for steel formwork?

- Steel formwork can be connected using several common methods, including welding, bolting, and clamping. Welding is a popular choice due to its ability to create strong and permanent connections by melting two steel components together. However, skilled labor and specialized equipment are necessary for welding. Bolting is another frequently used method, which involves joining steel components using bolts and nuts. This method offers a flexible and adjustable connection, allowing for easy disassembly and reassembly of formwork panels. It is also relatively quick and does not require highly skilled labor. Clamping, on the other hand, utilizes clamps or couplers to connect steel formwork components. This method is often employed for temporary structures or when quick assembly and disassembly are required. Like bolting, clamping provides a flexible and adjustable connection, but it does not require tools or additional hardware. The choice of connection method for steel formwork depends on various factors, such as project requirements, desired level of permanence, ease of assembly, and available resources. Each method has its own advantages and disadvantages, so it is crucial to select the most suitable one based on the specific needs of the project.

- Q: How does steel formwork affect the overall moisture resistance of the structure?

- Steel formwork does not directly affect the overall moisture resistance of the structure as it is primarily used as a temporary mold for concrete placement. However, if not properly sealed or if there are gaps between the steel formwork and the concrete, it can potentially lead to water infiltration and compromise the moisture resistance of the structure.

- Q: What are the different types of formwork anchors used in steel formwork?

- There are several types of formwork anchors that are commonly used in steel formwork. These anchors are essential for securing the formwork to the structure and ensuring the stability and safety of the construction process. Some of the different types of formwork anchors used in steel formwork include: 1. Wedge Anchor: This type of anchor consists of a threaded rod with a wedge-shaped end. It is inserted into a pre-drilled hole in the concrete structure and secured by tightening a nut on the threaded end. The wedge anchor provides a strong grip and is commonly used for securing formwork to concrete walls or slabs. 2. Screw Anchor: Screw anchors, also known as self-tapping anchors, are designed for use in softer materials such as wood or light-gauge steel. They have a threaded body that is screwed into the material, providing a secure connection for the formwork. Screw anchors are easy to install and remove, making them a popular choice for temporary formwork applications. 3. Hook Anchor: This type of anchor is shaped like a hook and is typically embedded into the concrete structure during the pouring process. The formwork is then attached to the hook using bolts or other fasteners. Hook anchors provide a strong and reliable connection and are commonly used in applications where high loads or lateral forces are expected. 4. Swift Lift Anchor: Swift lift anchors are specifically designed for lifting and handling precast concrete elements, including steel formwork. These anchors are embedded into the structure during the pouring process and provide a safe and efficient method for lifting and positioning the formwork. 5. Plate Anchor: Plate anchors consist of a flat plate with holes for bolts or other fasteners. They are commonly used in steel formwork systems to secure the formwork to the structure. Plate anchors are versatile and can be easily adjusted or relocated as needed. 6. Chemical Anchor: Chemical anchors are used when a strong and permanent connection is required. These anchors consist of a resin or adhesive that is injected into a pre-drilled hole in the concrete structure. The steel formwork is then attached to the chemical anchor, creating a secure bond. Each type of formwork anchor has its own unique advantages and is suitable for different applications. The choice of anchor will depend on factors such as the type of structure, the load requirements, and the duration of use. It is important to select the appropriate anchor and ensure proper installation to ensure the safety and stability of the formwork system.

- Q: Is steel formwork suitable for projects with heavy concrete loads?

- Yes, steel formwork is highly suitable for projects with heavy concrete loads. Steel formwork is known for its strength, durability, and load-bearing capacity, making it ideal for projects that involve heavy concrete loads. Steel formwork can withstand the pressure and weight of the concrete, ensuring that it maintains its shape and integrity throughout the pouring and curing process. Additionally, steel formwork offers excellent dimensional accuracy, allowing for precise and consistent concrete placement, which is crucial for projects with heavy loads. Overall, steel formwork is a reliable and robust choice for projects that require the support of heavy concrete loads.

Send your message to us

Ring-lock Scaffolding accessories for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords