Tabel-formwork for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

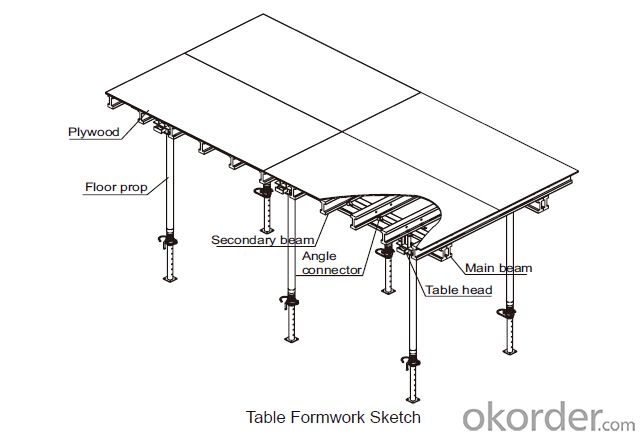

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: What are the different types of form ties used in steel formwork?

- There are several different types of form ties used in steel formwork, each designed to serve a specific purpose and meet specific requirements. 1. Coil Ties: These ties consist of a coil rod with two to four coils, which provide flexibility and allow for easy installation and removal. Coil ties are commonly used in lighter applications where relatively low pressure is expected. 2. Flat Ties: Flat ties are typically made of steel and have flat, wide plates on both ends. They are used to connect opposite wall forms, providing stability and preventing the forms from bulging or spreading due to the pressure of the concrete. 3. She-Bolt Ties: She-bolt ties consist of a threaded rod with a she-bolt attached to one end. These ties are used to secure wall forms together, and the threaded rod allows for easy adjustment of the formwork. 4. Snap Ties: Snap ties are a popular choice for fast and efficient formwork installation. They consist of a metal rod with a button-like head on one end and a wedge on the other. The button head is inserted into the formwork, and the wedge is then driven into the button head using a hammer, creating a strong connection. 5. Cone Ties: Cone ties are similar to snap ties, but they have a cone-shaped head instead of a button head. The cone head is inserted into the formwork, and a metal wedge is driven into the cone, securing the formwork. 6. Waler Ties: Waler ties are used to connect horizontal waler beams with vertical formwork members. They provide additional strength and stability to the formwork system. 7. Loop Ties: Loop ties are made of steel wire and have loops on both ends. They are used to secure wall forms together and can be easily removed once the concrete has cured. 8. Pin and Wedge Ties: Pin and wedge ties consist of a pin and a wedge. The pin is inserted into the formwork, and the wedge is driven into the pin, creating a tight and secure connection. These are just a few examples of the different types of form ties used in steel formwork. The choice of tie will depend on factors such as the type of construction, desired strength, ease of installation, and specific project requirements.

- Q: What is the standard thickness of steel formwork

- Opposite? The negative is not too clear. Generally if there is pellicle

- Q: Can steel formwork be used for elevated helipads?

- Yes, steel formwork can be used for elevated helipads. Steel formwork provides a strong and durable solution that can withstand the weight and impact of helicopters during takeoff and landing. Additionally, steel formwork can be customized to meet specific design requirements, allowing for the construction of elevated helipads with ease.

- Q: What are the different types of reinforcement used in steel formwork systems?

- There are several types of reinforcement used in steel formwork systems, each serving a specific purpose in enhancing the structural integrity and durability of the concrete structures. 1. Steel bars: Steel bars, also known as rebars, are commonly used in steel formwork systems to provide tensile strength to the concrete. These bars are placed in the formwork before pouring the concrete, and they help prevent cracking and ensure the stability of the structure. 2. Wire mesh: Wire mesh reinforcement is another commonly used type in steel formwork systems. It consists of a grid of interconnected steel wires that are welded or woven together. Wire mesh reinforcement helps in distributing the loads evenly across the concrete, improving its strength and reducing the risk of cracking. 3. Steel fibers: Steel fibers are small, discrete reinforcing elements that are often added to the concrete mix itself. These fibers enhance the tensile strength of the concrete, making it more resistant to cracking and improving its overall durability. Steel fibers are particularly useful in applications where traditional reinforcement may be difficult to install. 4. Stirrups and ties: Stirrups and ties are commonly used in reinforced concrete structures and are also incorporated into steel formwork systems. They are typically made of steel bars and are used to hold the main reinforcement bars in place and provide additional support to the structure. Stirrups and ties help prevent the rebars from shifting or bending during concrete placement and ensure proper alignment and spacing. 5. Steel plates and brackets: Steel plates and brackets are used in formwork systems to provide additional support and stability to the structure. They are typically attached to the formwork panels and act as reinforcement elements, helping distribute the loads and preventing deformation or failure. Overall, the different types of reinforcement used in steel formwork systems are essential in ensuring the strength, stability, and longevity of concrete structures. They work together to resist external forces, prevent cracking, and enhance the overall performance of the structure.

- Q: How does steel formwork contribute to the construction process?

- The importance of steel formwork cannot be overstated in the construction process as it plays a vital role in shaping and supporting concrete structures. It is utilized for creating walls, columns, beams, and slabs, offering the necessary support during the pouring and curing of concrete. One major advantage of steel formwork lies in its strength and durability. Steel possesses a high tensile strength, enabling it to withstand the pressure exerted by the weight of the concrete. This strength guarantees that the formwork remains intact and stable, preventing any deformation or collapse during construction. Furthermore, steel formwork is extremely versatile and can be tailored to any desired shape or size. This flexibility allows architects and engineers to design complex and unique structures that would be challenging to achieve with other formwork materials. The capacity to shape the formwork according to specific design requirements ensures that the final concrete structure is both functional and aesthetically pleasing. Moreover, steel formwork offers exceptional reusability. Unlike materials like wood or plywood, steel formwork can be reused multiple times without compromising its structural integrity. This reusability not only reduces construction costs but also minimizes waste and promotes sustainability in the construction industry. Another advantage of steel formwork is its ease of assembly and disassembly. It can be quickly installed and dismantled, facilitating faster construction cycles. This efficiency saves time and labor, leading to increased productivity and overall cost savings on construction projects. Furthermore, steel formwork provides a seamless and consistent finish to the concrete surface. The impermeable design of the steel panels prevents any leakage or seepage of concrete. This feature ensures that the concrete cures uniformly, resulting in a high-quality finish that meets the desired specifications. In conclusion, steel formwork makes a significant contribution to the construction process by providing strength, durability, versatility, reusability, ease of assembly, and a smooth finish to concrete structures. Its indispensable role in shaping and supporting concrete elements makes it an essential tool for modern construction projects.

- Q: Can steel formwork be customized for specific project requirements?

- Customization of steel formwork is possible to meet the specific requirements of a project. Steel, being highly versatile, can be shaped and molded easily to fit the unique needs of a project. This flexibility allows for the creation of different sizes, shapes, and designs to accommodate varying construction needs. On-site modification or adjustment of steel formwork is also achievable to align with the exact dimensions and specifications of a project. Furthermore, off-site pre-fabrication of steel formwork, tailored precisely to the project's requirements, is an option before transporting it to the construction site. By customizing steel formwork, it becomes suitable for a wide range of construction projects, including intricate structures, tall buildings, bridges, tunnels, and more.

- Q: How does steel formwork affect the overall flexibility of the construction process?

- The construction process can be significantly impacted by steel formwork, as it enhances overall flexibility. One of the main benefits of utilizing steel formwork is its exceptional strength and durability, which ensures the structural integrity of the formwork system while allowing for intricate and complex structures to be created. By employing steel formwork, there is greater flexibility in both design and construction. This enables the creation of more precise and accurate shapes, resulting in a higher level of architectural sophistication. Additionally, the ability to reuse the formwork multiple times reduces costs and increases efficiency in construction projects. Furthermore, the ease of assembly and disassembly of steel formwork leads to faster construction progress. This allows for shorter construction cycles, saving time and resources. The flexibility of steel formwork also permits adjustments and modifications during the construction process, facilitating adaptability to unforeseen changes or design revisions. Moreover, steel formwork provides enhanced safety and stability, ensuring a secure working environment for construction workers. Its high load-bearing capacity enables the construction of taller and more complex structures, expanding the possibilities in architectural design. Overall, the utilization of steel formwork enhances the flexibility of the construction process by enabling the construction of complex structures, offering design adaptability, reducing construction time, and improving safety. Its strength, durability, and reusability make it a preferred choice in the construction industry, leading to greater efficiency, accuracy, and innovation in building projects.

- Q: Are there any fire safety considerations when using steel formwork?

- Yes, there are fire safety considerations when using steel formwork. Steel is a non-combustible material, which means it does not catch fire or contribute to the spread of flames. However, during a fire, steel can lose its structural integrity and collapse more rapidly than other materials. Therefore, it is important to have proper fire protection measures in place, such as fire-resistant coatings or fireproofing materials, to ensure the safety of personnel and the structure when using steel formwork.

- Q: What are the different types of tie systems used in steel formwork?

- There are several different types of tie systems that are commonly used in steel formwork in construction projects. These tie systems are designed to provide stability and support to the formwork during the concrete pouring process. Some of the main types of tie systems used in steel formwork include: 1. Tie rods and wing nuts: This is the most commonly used tie system in steel formwork. It consists of steel rods that are inserted through the formwork panels and secured with wing nuts. This system allows for quick and easy assembly and disassembly of the formwork. 2. Shear connectors: Shear connectors are used in situations where there is a need to transfer shear forces between the formwork and the concrete. These connectors typically consist of steel bars that are embedded in the concrete and connected to the formwork. 3. Steel form ties: Steel form ties are used to hold the formwork panels together and maintain the desired shape and alignment during concrete pouring. These ties are typically made of steel and are available in various lengths and sizes to accommodate different formwork requirements. 4. Adjustable formwork systems: These systems are designed to provide flexibility in adjusting the formwork to different shapes and sizes. They often incorporate adjustable brackets and clamps that allow for easy and precise alignment of the formwork panels. 5. Stay-in-place formwork systems: Stay-in-place formwork systems are designed to remain in place after the concrete has cured, eliminating the need for formwork removal. These systems are typically used in applications where the formwork is intended to become a permanent part of the structure, such as in bridges or tunnels. Overall, the choice of tie system in steel formwork will depend on factors such as the project requirements, structural design, and the specific conditions of the construction site. It is important to select a tie system that can provide the necessary stability and support for the formwork, while also considering factors such as ease of installation, reusability, and cost-effectiveness.

- Q: Can steel formwork be used in tunnel construction projects?

- Certainly! Tunnel construction projects can indeed utilize steel formwork. When it comes to tunnel construction, steel formwork is widely preferred because of its durability, strength, and ability to be reused. This type of formwork offers a strong and reliable framework for pouring concrete, aiding in achieving precise and accurate dimensions in tunnel construction. Moreover, steel formwork is capable of withstanding the pressures exerted by the surrounding soil and the weight of the concrete, which guarantees the stability and safety of the tunnel structure. In addition to these advantages, steel formwork is resistant to corrosion and boasts a longer lifespan compared to other formwork options, making it an excellent choice for tunnel construction projects that require longevity.

Send your message to us

Tabel-formwork for Formwork and Scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords