Tabel-formwork for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

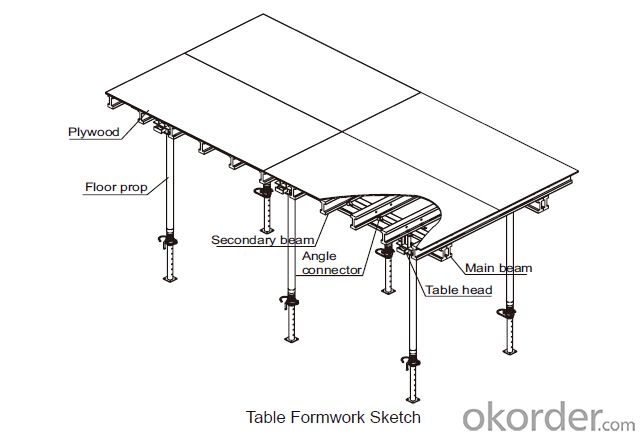

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel formwork be used for precast concrete arches?

- Yes, steel formwork can be used for precast concrete arches. Steel formwork provides a strong and durable structure for shaping and supporting the concrete during the casting process. It allows for the creation of precise and complex arch shapes, ensuring the desired architectural and structural requirements are met. Additionally, steel formwork can be easily customized and reused, making it a cost-effective option for precast concrete arches.

- Q: I was engaged in the patent agency, the two days of receipt of a patent application on the bridge, it is a drawing section map, the other nothing, no label no text, I am on mechanical, civil engineering drawings and utterly ignorant of ah, so simple, later on the Internet for a long time and recall ratio of patent it is unclear whether the drawings, sections of the box girder template, now the goal is clear, but a box girder template knowledge I don't know much about the Internet, did not find out what things, patent is only a few patents, I want to know more about the box girder and box girder template for example, the box girder template with cast-in-place prefabricated, full steel structure, steel wood structure, the hydraulic support system, but also ordinary (the ordinary I don't know what), etc. So, anyway, more detailed information as possible, thank you ~ ~ no more, I don't mind ah, not much, have a point with the province oh

- I am specialized in Civil Engineering (design and construction), you see the drawings are box girder template for the design of template

- Q: What are the common design considerations for steel formwork in cold climates?

- Several factors need to be taken into account when designing steel formwork in cold climates to ensure its structural integrity, safety, and efficiency. These considerations are crucial in extreme weather conditions. 1. The selection of the appropriate steel grade is crucial to withstand low temperatures without compromising strength. It is essential to choose high-quality steel with good cold resistance properties to prevent brittleness and potential failure. 2. Insulation materials should be incorporated into the design to minimize heat loss during concrete curing. Insulating the formwork walls and base can prevent freezing, which may cause cracking and reduced structural integrity. 3. Steel contracts in cold temperatures, leading to misalignment and buckling of the formwork. To accommodate thermal expansion and contraction, it is important to include expansion joints or flexible connections in the formwork design. 4. Proper anchoring and support systems need to be incorporated into the formwork design to ensure stability and prevent shifting or settling, especially in cold climates with freeze-thaw cycles that cause significant ground movement. 5. Cold and humid environments can accelerate corrosion of steel. Enhancing durability and prolonging the lifespan of the steel formwork can be achieved by incorporating corrosion-resistant coatings or galvanizing. 6. The formwork design should take into consideration the additional loads imposed by accumulated snow in cold climates with heavy snowfall. This is necessary to prevent overloading and potential collapse of the structure. 7. Cold temperatures can affect the performance of fastening systems, such as bolts and screws. It is crucial to use appropriate fasteners that can withstand low temperatures and prevent loosening due to thermal contraction. 8. Considering the ease of assembly and dismantling of the formwork is important in cold climates where extreme temperatures may hinder construction activities. Designing the formwork system with easy-to-use connections and fasteners can improve efficiency and reduce construction time. By taking these common design considerations into account, engineers and designers can ensure that steel formwork in cold climates is safe, reliable, and capable of withstanding the harsh conditions.

- Q: How does steel formwork handle different weather conditions?

- Steel formwork is highly durable and can withstand various weather conditions. It is resistant to moisture, extreme temperatures, and UV radiation. This makes it suitable for use in both hot and cold climates. Additionally, steel formwork does not warp, swell, or shrink, ensuring its stability and strength, even in challenging weather conditions.

- Q: What are the different types of edge protection used with steel formwork?

- There are several types of edge protection used with steel formwork to ensure safety and prevent accidents on construction sites. Some of the common types include: 1. Edge protection barriers: These are typically made of a sturdy material like steel or aluminum and are installed along the edges of the formwork. They act as a physical barrier to prevent workers from accidentally falling off the edge. Edge protection barriers are often adjustable and can be easily installed and removed as needed. 2. Toe boards: Toe boards are typically made of wood or steel and are installed along the lower edge of the formwork. They provide a barrier to prevent tools, equipment, or debris from falling off the edge. Toe boards also serve as a visual indicator, reminding workers to be cautious near the edge. 3. Handrails: Handrails are horizontal bars that are attached to vertical posts and are installed along the edges of the formwork. They provide a secure handhold for workers, helping them maintain balance and stability, especially when working at heights. Handrails are often required by safety regulations in certain situations. 4. Safety nets: Safety nets are installed below the formwork to catch any falling objects or debris. They are typically made of high-strength mesh material and are designed to absorb the impact of a falling object. Safety nets are useful when there is a risk of objects falling off the edge, such as during concrete pouring or during the removal of formwork. 5. Harnesses and lifelines: In certain high-risk situations, workers may be required to wear harnesses and use lifelines to protect themselves from falling. These systems consist of a harness that is worn by the worker and connected to a lifeline, which is securely anchored to a structure. Harnesses and lifelines provide an additional layer of protection in situations where edge protection alone may not be sufficient. It is important to note that the choice of edge protection will depend on the specific requirements of the project, local regulations, and the level of risk associated with the work being performed. It is crucial for construction companies to assess the site conditions and implement appropriate edge protection measures to ensure the safety of workers.

- Q: What are the different types of steel formwork clamps and connectors?

- There are several different types of steel formwork clamps and connectors used in construction projects. These clamps and connectors play a crucial role in holding the formwork together and maintaining its stability during the casting of concrete. Here are some of the common types: 1. Wedge clamps: These clamps are widely used and consist of a wedge-shaped piece that locks the formwork panels tightly together. They are easy to install and remove, making them popular for temporary formwork. 2. Rapid clamps: These clamps are designed for quick installation and removal. They have a spring-loaded mechanism that allows for easy adjustment and tightening. Rapid clamps are often used in situations where speed is essential, such as high-rise construction. 3. Scaffold clamps: As the name suggests, these clamps are used to connect formwork to scaffolding systems. They provide a secure connection between the two, ensuring stability and safety during construction. 4. Column clamps: These clamps are specifically designed for connecting formwork panels around columns or pillars. They come in various sizes to accommodate different column diameters and provide a strong and stable connection. 5. Corner clamps: Corner clamps are used to connect formwork panels at corners, ensuring a tight fit and preventing any gaps. They are adjustable, allowing for flexibility in formwork design and easy alignment of panels. 6. Beam clamps: These clamps are used to secure formwork panels to horizontal beams or joists. They provide a sturdy connection and help distribute the load evenly, ensuring the stability of the formwork system. 7. Pin and wedge connectors: These connectors consist of steel pins and wedges that are used to join formwork panels together. The pins are inserted into pre-drilled holes, and the wedges are hammered in to create a tight connection. Pin and wedge connectors offer a reliable and durable solution. 8. Tie rods and wing nuts: These components are used in conjunction with clamps to provide additional support and reinforcement to the formwork system. Tie rods are threaded steel rods that are inserted through the formwork panels and secured with wing nuts, creating a strong and rigid connection. It is important to note that the specific types of clamps and connectors used may vary depending on the project requirements and the formwork system being used. Consulting with a structural engineer or formwork supplier is recommended to determine the most suitable clamps and connectors for a particular construction project.

- Q: How does steel formwork accommodate for different concrete pouring rates?

- Steel formwork is a versatile construction material that can easily accommodate different concrete pouring rates. The adjustable nature of steel formwork allows for quick and efficient adjustments to be made to match the required pouring rate. One way steel formwork accommodates for different pouring rates is through its modular and customizable design. Steel formwork can be easily assembled and disassembled, allowing for the construction of any desired shape or size. This flexibility enables construction teams to adjust the formwork to accommodate different pouring rates as needed. For example, if a higher pouring rate is required, additional formwork panels can be added to increase the capacity and ensure the concrete can be poured at a faster pace. Moreover, steel formwork is known for its robustness and strength. This means that it can withstand the pressure exerted by the concrete during pouring, regardless of the pouring rate. The sturdiness of steel formwork prevents any deformation or collapse, ensuring the concrete is properly contained and shaped according to the desired structure. Additionally, steel formwork offers excellent reusability, allowing it to be used for multiple construction projects. This reusability factor makes it a cost-effective choice, as the initial investment in steel formwork can be easily recovered over time. Consequently, construction teams can adapt the formwork to different pouring rates without incurring significant additional expenses. In conclusion, steel formwork is a highly adaptable construction material that can easily accommodate different concrete pouring rates. Its modular design, strength, and reusability make it a preferred choice in construction projects where pouring rates may vary. With steel formwork, construction teams have the flexibility to adjust the formwork to match the required pouring rate, ensuring a smooth and efficient concrete pouring process.

- Q: Can steel formwork be used in tunnel construction?

- Yes, steel formwork can be used in tunnel construction. Steel formwork is widely used in construction projects, including tunnel construction, due to its durability, strength, and versatility. It provides a rigid support structure that can withstand the pressure and stress exerted by the surrounding soil and rock in tunneling operations. Steel formwork is designed to be easily assembled and disassembled, allowing for efficient tunnel construction. It can be customized to fit the specific shape and dimensions of the tunnel, ensuring accurate and precise formwork. Additionally, steel formwork can be reused multiple times, making it a cost-effective solution for tunnel construction projects.

- Q: What are the considerations when designing steel formwork for dams?

- When designing steel formwork for dams, several key considerations need to be taken into account. Firstly, the structural stability and strength of the formwork is of utmost importance. Dams are large structures that exert significant forces, so the formwork needs to be able to withstand these forces without any deformation or failure. This requires careful analysis and design of the formwork system, including the selection of appropriate steel grades, sizes, and reinforcement. Another important consideration is the water pressure that the formwork will be subjected to during the construction and operation of the dam. The formwork needs to be watertight to prevent any leakage or seepage, as this can compromise the stability and integrity of the dam. Special attention should be given to the joints and connections of the formwork to ensure a tight and secure seal. Durability is another factor that needs to be considered when designing steel formwork for dams. Dams have a long design life, often spanning several decades, so the formwork needs to be able to withstand prolonged exposure to various environmental conditions, such as temperature changes, moisture, and chemical exposure. The formwork should be protected against corrosion, either through the use of corrosion-resistant steel or by applying protective coatings. The ease of assembly and disassembly is also an important consideration. Dams are complex structures that require a large number of formwork elements to be assembled and aligned accurately. The formwork system should be designed in a way that allows for easy and efficient installation and removal, minimizing the time and effort required for construction. Lastly, cost considerations play a significant role in the design of steel formwork for dams. The formwork system needs to be cost-effective and efficient, maximizing the use of materials and minimizing waste. The design should also take into account the availability and cost of steel, as well as the availability of skilled labor for fabrication and installation. Overall, the considerations when designing steel formwork for dams include structural stability, watertightness, durability, ease of assembly, and cost-effectiveness. By carefully addressing these factors, engineers can ensure the successful construction and long-term performance of the dam.

- Q: What are the typical safety certifications for steel formwork systems?

- Steel formwork systems typically require several safety certifications to ensure their quality and adherence to safety standards. These certifications include: 1. ISO 9001: This certification guarantees that the manufacturer has implemented a quality management system, covering design, production, and installation procedures. It ensures that the system meets the necessary standards and specifications. 2. European Conformity (CE) Marking: Mandatory for steel formwork systems sold in the European Union, this certification confirms compliance with essential health and safety requirements. The CE marking guarantees rigorous testing and adherence to necessary safety standards. 3. Occupational Safety and Health Administration (OSHA) Compliance: In the United States, steel formwork systems must comply with OSHA's safety regulations. These regulations encompass fall protection, scaffolding safety, and other safety measures. Compliance ensures the safety of workers involved in installation and use. 4. American National Standards Institute (ANSI) Certification: ANSI provides certifications for various products, including steel formwork systems. Certification signifies that the system meets specific safety and performance requirements, providing assurance to users that it has undergone thorough testing and meets industry standards. 5. International Code Council Evaluation Service (ICC-ES) Certification: This certification independently verifies compliance with International Building Code (IBC) requirements. It ensures that the system has been evaluated and deemed safe for use in construction projects. These safety certifications are crucial for steel formwork systems to demonstrate compliance with industry standards, ensuring worker safety and system reliability during construction projects. Manufacturers and suppliers must obtain these certifications to instill confidence in their products and facilitate their use in construction projects worldwide.

Send your message to us

Tabel-formwork for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords