Tabel formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

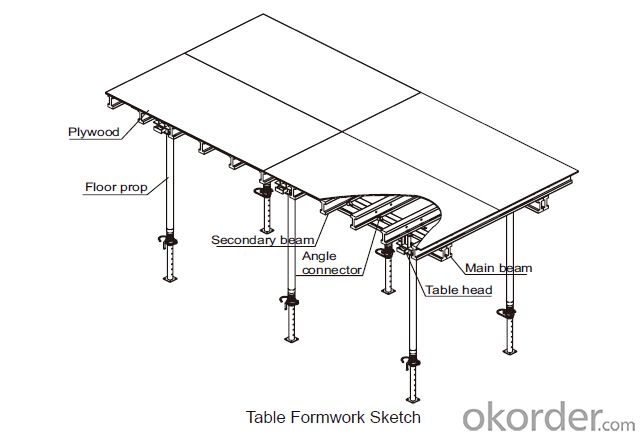

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: What are the common accessories and attachments used with steel formwork systems?

- Enhancing functionality and efficiency, steel formwork systems utilize various common accessories and attachments. These include: 1. Securing the steel formwork panels together, formwork clamps offer stability and prevent any movement during concrete pouring. 2. Connecting the steel formwork panels and maintaining their desired position, formwork ties evenly distribute pressure to prevent bulging or deformation. 3. Providing additional strength and stability, adjustable steel props support the weight of the formwork and freshly poured concrete, ensuring proper alignment and preventing collapse. 4. Attaching the formwork to existing structures or creating additional support, formwork brackets help maintain desired shape and stability during concrete pouring. 5. Enabling sharp corners and angles in the formwork, formwork corners ensure accurate concrete pouring and shape preservation. 6. Maintaining proper spacing between formwork panels, formwork spacers ensure even and uniform concrete pouring for a smooth finish. 7. Preventing concrete from sticking to steel panels, formwork release agents are applied to the formwork surface for easy removal after concrete curing. 8. Ensuring level and proper alignment of the formwork, formwork leveling devices contribute to a consistent and uniform concrete finish. In summary, these essential accessories and attachments are pivotal in successfully implementing steel formwork systems. They improve structural integrity, enhance efficiency, and guarantee high-quality finishes for constructed concrete structures.

- Q: How does steel formwork affect the quality of concrete?

- Steel formwork can have a significant impact on the quality of concrete in several ways. Firstly, steel formwork provides a rigid and stable structure that holds the concrete in place during the pouring and curing process. This ensures that the concrete maintains its desired shape and form, preventing any distortion or deformation. Secondly, steel formwork allows for precise and accurate construction of concrete structures. The smooth and even surface of steel formwork helps to create a uniform finish on the concrete, reducing the likelihood of surface imperfections such as air bubbles, honeycombing, or unevenness. This results in a higher quality and more aesthetically pleasing concrete finish. Furthermore, steel formwork offers better dimensional stability compared to other types of formwork materials. It is less susceptible to expansion or contraction due to temperature changes or moisture absorption, which can cause cracks or distortions in the concrete. This ensures that the structural integrity of the concrete remains intact, enhancing its overall quality and durability. Additionally, steel formwork provides excellent strength and load-bearing capacity. This allows for the construction of larger and more complex concrete structures with higher structural integrity. The sturdy nature of steel formwork ensures that the concrete can withstand heavy loads and external forces, reducing the risk of structural failures or collapses. Moreover, steel formwork is reusable, making it a cost-effective option in the long run. This not only contributes to sustainability but also ensures consistent quality in concrete construction. The ability to reuse steel formwork reduces the risk of formwork failure or deterioration that could affect the quality of subsequent concrete pours. In conclusion, steel formwork plays a crucial role in enhancing the quality of concrete. It provides stability, precision, dimensional stability, strength, and reusability, all of which contribute to the overall quality and durability of concrete structures.

- Q: Can steel formwork be used for both residential and industrial projects?

- Yes, steel formwork can be used for both residential and industrial projects. Steel formwork is a durable and robust system that can withstand heavy loads and provide excellent support for concrete structures. It is commonly used in various construction projects, including residential buildings and industrial facilities. The versatility of steel formwork allows it to be easily adapted and customized to meet the specific requirements of different projects. Its strength and durability make it suitable for both small-scale residential construction and large-scale industrial projects. Additionally, steel formwork offers several advantages such as high reusability, easy maintenance, and faster construction compared to traditional formwork systems. Therefore, steel formwork is a reliable and efficient option that can be used in a wide range of construction projects, regardless of their scale or purpose.

- Q: What is the maximum concrete pressure that steel formwork can withstand?

- The ability of steel formwork to withstand the maximum pressure of concrete depends on various factors, including the specific design and construction of the formwork system. However, when compared to other types of formwork materials, steel formwork generally has the capacity to withstand higher concrete pressures. Typically, the maximum concrete pressure that steel formwork can endure ranges from 50 to 100 kilonewtons per square meter (kN/m²) or 7.2 to 14.4 pounds per square inch (psi). This level of pressure is suitable for a wide range of construction projects, such as high-rise buildings, bridges, and other structures that involve substantial concrete pours. It is worth noting that the determination of the maximum concrete pressure that steel formwork can withstand should always be carried out by a qualified engineer or designer. They will take into account factors like the height and thickness of the concrete pour, the arrangement and dimensions of the formwork supports, and the strength and stability of the steel formwork system. By adhering to the recommended limits for maximum concrete pressure, construction professionals can ensure the safety and integrity of the formwork system. This will help minimize the risk of failure or collapse and ensure the successful pouring of concrete.

- Q: What are the common connection methods for steel formwork?

- The common connection methods for steel formwork include welding, bolting, and using connecting plates or brackets.

- Q: How does steel formwork affect the overall sustainability of a concrete structure?

- The overall sustainability of a concrete structure can be significantly influenced by steel formwork. To begin with, the reusability of steel formwork allows for its utilization in multiple construction projects, thereby reducing the need for additional materials and minimizing waste. This reusability also aids in decreasing the environmental impact associated with the production and disposal of formwork materials. Furthermore, the durability and robustness of steel formwork ensure that it can endure repeated use without compromising its structural integrity. This durability extends the lifespan of the formwork, resulting in fewer replacements and less waste generation. Additionally, steel formwork provides superior strength and stability, enabling the construction of concrete structures with greater precision and efficiency. This allows for the use of less concrete, thereby reducing the overall carbon footprint of the structure. Moreover, the utilization of steel formwork can lead to quicker construction times, which in turn reduces energy consumption and minimizes the project's environmental impact. Moreover, steel formwork allows for greater flexibility in design and construction techniques, thus enabling the development of more sustainable structures. It can be easily customized to fit various shapes and sizes, optimizing space usage and reducing material wastage. This flexibility also allows for the incorporation of sustainable features such as energy-efficient insulation, green roofs, or rainwater harvesting systems. In conclusion, steel formwork positively influences the overall sustainability of a concrete structure through its reusability, durability, strength, and flexibility. By reducing waste generation, minimizing the use of concrete, and enabling sustainable design options, steel formwork contributes to the creation of more environmentally-friendly and efficient structures.

- Q: How does steel formwork affect the overall thermal performance of the building?

- Steel formwork can have a significant impact on the overall thermal performance of a building. The thermal performance of a building refers to its ability to effectively regulate heat transfer between the interior and exterior environments. One key aspect of steel formwork that affects thermal performance is its conductivity. Steel is a highly conductive material, meaning it can easily transfer heat. This can result in higher heat transfer rates between the inside and outside of the building, which can lead to increased energy consumption for heating and cooling. Additionally, steel formwork can create thermal bridging. Thermal bridging occurs when there is a continuous path of high thermal conductivity, such as steel, that allows heat to bypass insulation. This can result in localized areas of heat loss or gain, reducing the overall effectiveness of insulation and compromising the thermal performance of the building. To mitigate these issues, various strategies can be employed when using steel formwork. One approach is to incorporate thermal breaks into the formwork system. Thermal breaks are insulating materials that are placed between the steel and the concrete, reducing the conductivity and minimizing thermal bridging. This helps to maintain a more consistent temperature throughout the building envelope and improves overall energy efficiency. Another strategy is to augment the insulation system by adding additional insulation layers to compensate for the heat transfer through the steel formwork. This can be done by applying insulation materials over the formwork or incorporating insulating layers within the concrete structure itself. Overall, while steel formwork can potentially have a negative impact on the thermal performance of a building, proper design considerations and the use of insulation and thermal break systems can help mitigate these effects and ensure a more energy-efficient and comfortable indoor environment.

- Q: How does steel formwork differ from other types of formwork?

- Steel formwork differs from other types of formwork in several ways. Firstly, steel formwork is highly durable and can be used multiple times, whereas other types of formwork such as wood or plywood may need to be replaced after a few uses. Additionally, steel formwork provides a smooth and precise finish, resulting in high-quality concrete structures. It also offers a higher load-bearing capacity, allowing for the construction of larger and more complex structures. Moreover, steel formwork can be easily fabricated and assembled, reducing construction time and labor costs. Overall, steel formwork is a more robust, efficient, and cost-effective solution compared to other types of formwork.

- Q: Are there any specific safety guidelines for steel formwork construction?

- During steel formwork construction, it is crucial to adhere to specific safety guidelines. These guidelines encompass various aspects: 1. Personal Protective Equipment (PPE): Workers involved in steel formwork construction must wear appropriate PPE, including hard hats, safety goggles, gloves, and steel-toed boots. This ensures protection from potential hazards like falling objects, flying debris, and impact injuries. 2. Fall Protection: To prevent falls from heights, adequate fall protection measures must be implemented. Depending on the nature and height of the work, this may involve using guardrails, safety nets, or personal fall arrest systems (PFAS). 3. Structural Stability: Before commencing construction, it is vital to ascertain that the steel formwork structure is stable and adequately braced to prevent collapse or structural failure. Regular inspections should be conducted to detect any signs of weakness or damage, with immediate corrective actions taken. 4. Proper Handling and Storage: Steel formwork components should be handled with care and stored securely to prevent accidents and injuries. Adhering to safe lifting techniques is necessary to avoid strains and muscle injuries. 5. Electrical Safety: If electrical equipment is utilized during the construction process, it is important to follow electrical safety guidelines. This includes grounding the equipment, using proper insulation, and ensuring secure electrical connections. 6. Hazard Communication: All workers must be aware of the potential hazards associated with steel formwork construction. Proper communication and training programs should be in place to educate workers about these hazards and the necessary safety precautions. 7. Regular Maintenance: Regular inspections and maintenance should be conducted on the steel formwork system to ensure its integrity and safe use. Prompt repair or replacement should be carried out for any identified defects or damages. It is important to note that these guidelines may vary depending on the specific project, local regulations, and industry best practices. It is advisable to consult industry experts and adhere to any additional safety guidelines that may apply to the particular steel formwork construction project.

- Q: Can steel formwork be used for both flat and sloped concrete surfaces?

- Steel formwork is capable of being used on concrete surfaces that are both flat and sloped. It is renowned for its adaptability and strength, rendering it appropriate for a range of concrete structures. Easy adjustment and shaping enable the creation of diverse architectural designs, whether flat or sloped. Moreover, steel formwork offers exceptional support and stability to the concrete during pouring and curing, guaranteeing a uniform and high-quality finish on both flat and sloped surfaces.

Send your message to us

Tabel formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords