Tabel Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

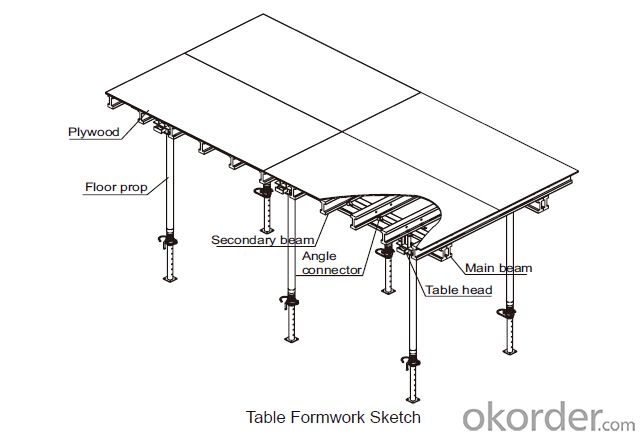

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel formwork be recycled?

- Yes, steel formwork can be recycled. Steel is a highly recyclable material and can be repurposed for various applications after its use as formwork. When the formwork is no longer needed, it can be collected and sent to a recycling facility where it will be processed and turned into new steel products. Recycling steel formwork helps to conserve natural resources, reduce energy consumption, and minimize waste going to landfills. It is an environmentally sustainable practice that many construction companies and contractors are adopting to promote a circular economy.

- Q: How does steel formwork accommodate for different concrete curing durations?

- Steel formwork is a versatile and durable option for concrete construction projects that allows for accommodating different concrete curing durations effectively. One way steel formwork accommodates for different concrete curing durations is by providing a stable and rigid structure that ensures the concrete retains its shape and strength during the curing process. The steel panels and frames used in formwork are designed to withstand the pressure exerted by the fresh concrete, preventing any deformation or collapse. Additionally, steel formwork allows for easy removal and reassembly, providing flexibility in adjusting the formwork setup to match the required curing duration. This is particularly useful in cases where different sections of the concrete structure need varying curing durations due to factors such as structural requirements or environmental conditions. Furthermore, steel formwork can be easily modified or adjusted to accommodate the use of various curing techniques. For instance, if a project requires accelerated curing methods, such as the use of steam or heat, steel formwork can be adapted to incorporate the necessary insulation or heating elements. This promotes faster curing while maintaining the stability and integrity of the formwork. Moreover, steel formwork offers efficient handling and transportation, allowing for the swift repositioning or removal of forms as required. This is especially advantageous when dealing with time-sensitive projects where different sections of the structure may need to be cured at different times. In summary, steel formwork accommodates for different concrete curing durations by providing a strong and stable structure that supports the concrete during the curing process. Its versatility allows for easy adjustment and modification to cater to varying curing techniques, while its ease of handling and transportation facilitates efficient repositioning or removal of formwork.

- Q: How does steel formwork affect the overall energy efficiency of a structure?

- Steel formwork can have a significant impact on the overall energy efficiency of a structure. Firstly, steel formwork is known for its durability and strength, which allows it to be reused multiple times. This reusability reduces the need for new formwork materials, thereby minimizing waste generation and conserving resources. By reducing the amount of waste produced during construction, the overall environmental impact is reduced, leading to improved energy efficiency. Additionally, steel formwork offers excellent thermal properties. It has a high thermal mass, meaning it can absorb and store heat energy effectively. This characteristic helps regulate the temperature inside the structure, reducing the reliance on heating or cooling systems. By stabilizing the internal temperature, the energy consumption for climate control is reduced, resulting in improved energy efficiency and lower operational costs. Furthermore, steel formwork enables the construction of energy-efficient designs. Its versatility allows for complex shapes and configurations, facilitating the integration of energy-saving elements such as insulation, ventilation systems, and renewable energy technologies. These features contribute to the overall energy performance of the structure, enhancing its efficiency and sustainability. Overall, steel formwork positively impacts the energy efficiency of a structure by reducing waste, providing excellent thermal properties, and enabling energy-efficient designs. By utilizing steel formwork, construction projects can achieve higher levels of sustainability and contribute to a greener and more energy-efficient built environment.

- Q: What are the different types of steel alloys used in formwork manufacturing?

- There are several types of steel alloys that are commonly used in formwork manufacturing due to their specific properties and characteristics. These alloys include: 1. Mild Steel: Mild steel, also known as low carbon steel, is a popular choice for formwork manufacturing due to its affordability and versatility. It has a relatively low amount of carbon and is easy to work with, making it suitable for various formwork applications. 2. High-strength Steel: High-strength steel alloys, such as high-strength low-alloy (HSLA) steel, are known for their increased strength and durability. These alloys have higher levels of carbon and other alloying elements, making them ideal for formwork that requires high load-bearing capacity and resistance to deformation. 3. Stainless Steel: Stainless steel is widely used in formwork manufacturing due to its excellent corrosion resistance properties. This alloy contains a minimum of 10.5% chromium, which forms a thin protective layer on its surface, preventing rust and corrosion. Stainless steel is particularly suitable for formwork used in marine or highly corrosive environments. 4. Tool Steel: Tool steel is a type of high-carbon alloy steel that is specifically designed for tool and die applications. It offers excellent hardness, wear resistance, and toughness, making it suitable for formwork manufacturing where a high level of precision and durability is required. 5. Alloy Steel: Alloy steel is a broad category that includes various types of steel alloys with specific properties tailored for different applications. These alloys are made by adding elements such as chromium, nickel, molybdenum, or tungsten to improve their strength, hardness, and corrosion resistance. Alloy steel can be used in formwork manufacturing that requires specific mechanical properties. Overall, the choice of steel alloy for formwork manufacturing depends on the specific requirements of the project, including load-bearing capacity, corrosion resistance, durability, and cost-effectiveness.

- Q: How does steel formwork handle different concrete early age strength development?

- Steel formwork is a versatile and durable option for handling different concrete early age strength development. Due to its strength and rigidity, steel formwork provides excellent support during the initial stages of concrete curing. It can withstand the high pressures exerted by fresh concrete, ensuring that the formwork remains intact and stable during the early age strength development. Additionally, steel formwork allows for efficient and precise placement of concrete, enabling proper consolidation and uniform curing. Overall, steel formwork is a reliable choice that can effectively handle the varying early age strength development of concrete.

- Q: What are the different finishes that can be achieved with steel formwork?

- There are several different finishes that can be achieved with steel formwork, depending on the desired aesthetic and functional requirements of the project. 1. Smooth Finish: Steel formwork can be designed to create a smooth surface on the concrete. This finish is often preferred for architectural applications where a clean and seamless appearance is desired. It provides a visually pleasing result and is commonly used in the construction of high-end buildings. 2. Textured Finish: Steel formwork can also be used to create textured finishes on the concrete surface. This can be achieved by using form liners or by incorporating patterns, designs, or textures onto the steel formwork itself. Textured finishes add visual interest and can be used to mimic natural materials such as stone, wood, or brick. 3. Exposed Aggregate Finish: Steel formwork can be designed to expose the aggregate in the concrete surface. This finish creates a rough and textured appearance, showcasing the natural beauty of the aggregates used. Exposed aggregate finishes are commonly used in decorative applications such as sidewalks, driveways, and patios. 4. Stamped Finish: Steel formwork can be used in conjunction with rubber stamps to create stamped finishes on the concrete surface. This technique allows for the creation of intricate patterns and designs, such as brick, tile, or stone imprints. Stamped finishes are often used to add decorative elements to concrete floors, walls, or pavements. 5. Polished Finish: Steel formwork can be utilized to achieve a polished finish on the concrete surface. This involves grinding and polishing the concrete to create a smooth, glossy, and reflective surface. Polished finishes are commonly used in commercial and residential buildings, as well as in high-traffic areas where a durable and low-maintenance surface is desired. Overall, steel formwork provides a versatile and flexible solution for achieving various finishes in concrete construction. The choice of finish will depend on the specific design requirements, project goals, and desired aesthetic outcome.

- Q: How does steel formwork impact the overall construction productivity?

- Steel formwork has a significant impact on overall construction productivity due to its numerous advantages over other types of formwork systems. Firstly, steel formwork is highly durable and can withstand multiple uses, making it a cost-effective option for construction projects. Unlike traditional timber formwork, steel formwork does not warp or shrink, ensuring consistent dimensions and reducing the need for frequent repairs or replacements. This durability saves time and money by eliminating the delay caused by formwork maintenance or replacement. Additionally, steel formwork offers superior strength and stability, allowing for the construction of larger and more complex structures. The rigid and sturdy nature of steel formwork ensures that it can support heavy concrete loads without any deformation or collapse. This strength and stability not only enhance the safety of the construction site but also facilitate the construction process by enabling faster pouring of concrete and reducing the need for additional support structures. Moreover, steel formwork is highly versatile and can be easily customized to meet specific project requirements. It can be easily assembled, disassembled, and repositioned, allowing for efficient use in various construction phases. This flexibility saves time and effort as it eliminates the need for constantly constructing new formwork for different parts of the structure. The ability to reuse steel formwork also reduces material waste, further contributing to improved productivity. Furthermore, steel formwork offers better surface finishes compared to other formwork systems. Its smooth and rigid surface ensures that the concrete achieves a high-quality finish, reducing the need for additional finishing work such as plastering or leveling. This results in time savings and improved overall construction productivity. In conclusion, steel formwork positively impacts overall construction productivity by providing durability, strength, stability, versatility, and high-quality finishes. Its long-lasting nature, ease of use, and ability to withstand heavy concrete loads contribute to reduced downtime and increased efficiency on construction sites. With these advantages, steel formwork proves to be an essential component in enhancing construction productivity.

- Q: How does steel formwork contribute to the overall stability of a structure?

- The construction industry greatly relies on steel formwork to ensure the stability of structures. This crucial component is extensively used for casting concrete elements like walls, slabs, columns, and beams. Steel formwork enhances stability by providing a rigid and robust framework for pouring and setting concrete. The steel panels and frames are designed to withstand the pressure exerted by wet concrete, preventing deformation during the curing process. This prevents any potential structural deficiencies or unevenness that may compromise stability. Moreover, steel formwork offers exceptional strength and durability, making it suitable for various construction projects. Its high tensile strength enables it to bear heavy loads, which is especially important for large-scale structures. Additionally, the formwork's strength allows for multiple reuses, reducing construction costs and environmental impact. Furthermore, steel formwork ensures excellent dimensional stability, maintaining its shape and dimensions throughout the construction process. This characteristic is crucial for structural accuracy and consistency. Additionally, steel formwork is highly resistant to moisture and other environmental factors that can affect stability. Its corrosion-resistant properties make it suitable for outdoor construction sites exposed to rain, humidity, and other elements. This resistance to corrosion ensures the formwork's integrity over time, contributing to the long-term stability of the structure. In conclusion, steel formwork plays a vital role in enhancing the stability of structures. Its rigid and robust framework, combined with its strength, durability, dimensional stability, and resistance to environmental factors, ensures proper concrete formation and structural integrity. By providing a stable foundation for the construction process, steel formwork significantly contributes to the stability and safety of the final structure.

- Q: Can steel formwork be used for both vertical and horizontal concrete elements?

- Yes, steel formwork can be used for both vertical and horizontal concrete elements. Steel formwork is highly versatile and can be easily assembled and disassembled, making it suitable for various types of concrete structures. It provides a strong and durable support system for pouring concrete, ensuring the desired shape and finish of the concrete element. Whether it is for walls, columns, beams, slabs, or any other concrete component, steel formwork can be tailored and adjusted to meet the specific requirements of the project. Its ability to withstand high pressure and heavy loads makes it ideal for both vertical and horizontal applications. Additionally, steel formwork can be reused multiple times, making it a cost-effective solution for construction projects.

- Q: Can steel formwork be used for precast concrete columns?

- Yes, steel formwork can be used for precast concrete columns. Steel formwork offers several advantages for precast concrete column construction. Firstly, steel formwork is durable and can withstand the pressure exerted by the concrete during the casting process. This ensures that the formwork maintains its shape and integrity, resulting in accurately shaped columns. Additionally, steel formwork provides a smooth and consistent surface finish to the concrete columns. This is important for aesthetic purposes, as well as ensuring that the columns meet the required specifications. Steel formwork also allows for easy demolding and reusability, which can significantly reduce construction time and cost. Furthermore, steel formwork can be easily customized and adapted to different column designs and dimensions. This flexibility makes it suitable for a wide range of precast concrete column applications, including various shapes and sizes. However, it is important to consider certain factors when using steel formwork for precast concrete columns. The weight of the steel formwork should be adequately supported to prevent any deformation or collapse during the casting process. Additionally, proper precautions should be taken to prevent rusting or corrosion of the steel formwork, as this can affect the quality of the concrete. Overall, steel formwork is a viable option for precast concrete column construction, offering durability, flexibility, and ease of use.

Send your message to us

Tabel Formwork for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords