Tabel Formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

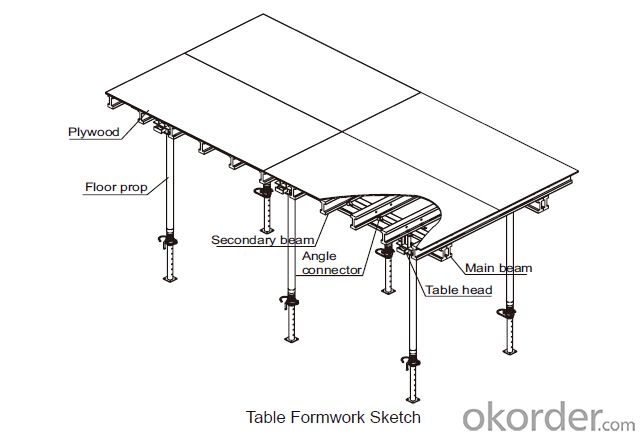

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: How does steel formwork handle concrete curing time?

- Steel formwork is an ideal choice for handling concrete curing time due to its durability and strength. It can withstand the pressure exerted by fresh concrete during the curing process without deforming or breaking, ensuring that the concrete retains its desired shape and strength. Additionally, steel formwork allows for faster curing times as it provides excellent heat dissipation, allowing the concrete to cool down uniformly and solidify quickly. This reduces the overall construction time and increases efficiency.

- Q: How does steel formwork impact the overall cost of a construction project?

- Steel formwork can impact the overall cost of a construction project by increasing initial expenses due to higher material costs. However, it offers long-term cost benefits through its durability, reusability, and reduced labor requirements. The strength and stability of steel formwork result in fewer repairs and replacements, leading to decreased maintenance expenses. Additionally, its ability to be used multiple times reduces the need for purchasing new formwork for future projects, ultimately lowering overall construction costs.

- Q: How are steel formwork systems assembled and disassembled?

- A simple and efficient process is used to assemble and disassemble steel formwork systems. The process begins by erecting the steel panels, which interlock with each other using connecting devices like pins, wedges, or clips. These panels come in various sizes and shapes to meet different construction needs. To assemble the steel formwork system, the panels are aligned and connected based on the desired shape and dimensions of the structure. Pins or wedges are commonly used to secure the panels and prevent movement during concrete pouring. Once the panels are connected, support structures such as walers, props, and braces are installed. Walers are horizontal beams that connect the vertical panels, while props provide additional stability as adjustable vertical supports. Braces help resist lateral forces. During concrete pouring, the steel formwork system holds the wet concrete in place, giving shape and finish to the structure. After the concrete has cured and gained strength, the dismantling process begins. To disassemble the steel formwork system, the props and braces are removed first, followed by the walers. Once the support structures are taken down, the panels can be easily detached by removing the connecting devices. This can be done by pulling out pins or wedges or releasing clips. The disassembly process follows a systematic approach, starting from the top and moving downwards to ensure safety and prevent accidental collapse. It is important to follow safety guidelines and use appropriate tools to avoid damage to the formwork system or injury to workers. In conclusion, steel formwork systems are assembled by connecting panels and installing support structures, while the disassembly process involves removing support structures and disconnecting panels. This systematic approach ensures a safe and efficient construction process, allowing for the reuse of the formwork system in future projects.

- Q: How does steel formwork handle different concrete expansion properties?

- Steel formwork is a highly durable and rigid material that can easily handle different concrete expansion properties. Its strength and stiffness allow it to withstand the pressure exerted by expanding concrete without deforming or cracking. Additionally, steel formwork is typically designed with expansion joints or gaps, which provide sufficient space for the concrete to expand and contract without causing any structural issues. This ensures that the formwork remains intact and maintains its shape, allowing for successful concrete pouring and curing.

- Q: Can steel formwork be used for underground construction projects?

- Underground construction projects can indeed utilize steel formwork. Steel formwork proves to be a versatile and enduring option for erecting different types of structures, even those situated below ground level. It offers a robust and firm support system capable of withstanding the pressures and loads associated with underground construction. When it comes to constructing underground projects like tunnels, basements, or subways, steel formwork presents several advantages. Firstly, it boasts a high load-bearing capacity and structural integrity, making it suitable for enduring the weight and pressure exerted by the surrounding soil or water. This ensures the safety and stability of the structure being erected. Furthermore, steel formwork exhibits resistance to corrosion, a crucial attribute in underground construction where exposure to water, humidity, and other corrosive elements is prevalent. This corrosion resistance guarantees the longevity and durability of the formwork, minimizing maintenance needs and extending the lifespan of the structure. Moreover, steel formwork offers design flexibility and can be easily tailored to meet specific project requirements. It can be fabricated into various shapes and sizes, enabling the construction of intricate underground structures. The modular nature of steel formwork also facilitates effortless assembly, disassembly, and reusability, proving advantageous for projects that necessitate frequent formwork repositioning. In conclusion, steel formwork proves to be a suitable choice for underground construction projects due to its strength, durability, corrosion resistance, and design flexibility. It provides a dependable and efficient solution for erecting underground structures, ensuring their safety and longevity.

- Q: What are the different types of finishes available for steel formwork?

- Steel formwork offers a variety of finishes, each with its own advantages and characteristics. Here are some commonly used finishes: 1. Smooth finish: This is the most basic option, leaving the steel formwork untreated. It creates a clean and smooth surface, perfect for achieving a polished concrete finish. 2. Galvanized finish: To protect against corrosion, the steel formwork is coated with a layer of zinc. This durable finish can withstand harsh weather conditions, so it is ideal for outdoor applications. 3. Powder-coated finish: A dry powder is applied to the steel formwork and then baked on, resulting in a decorative and long-lasting coating. It is resistant to chipping, scratching, and fading, and offers a wide range of colors for customization. 4. Painted finish: Another common choice is to paint the steel formwork. This not only enhances its aesthetics but also provides protection against corrosion. The type of paint used can vary based on project requirements, such as epoxy or acrylic paints. 5. Shot-blasted finish: By projecting small steel shots at high velocity onto the formwork surface, shot blasting removes impurities, rust, or old coatings, creating a clean and textured finish. This type of finish is often desired for better concrete adhesion. 6. Treated finish: Some steel formwork can be treated with special coatings or chemicals to enhance its properties. For instance, anti-stick coatings prevent concrete from sticking to the formwork, making it easier to remove after curing. Other treatments may include rust inhibitors or fire-resistant coatings. When choosing a finish for steel formwork, factors such as intended use, environmental conditions, desired aesthetics, and budget should be considered. Consulting a professional or manufacturer can help determine the most suitable finish for a specific project.

- Q: What are the common challenges faced during steel formwork transportation?

- Some common challenges faced during steel formwork transportation include the heavy weight of the formwork, which may require specialized equipment and vehicles for transportation, potential damage to the formwork during loading and unloading, and the need for careful handling and securing to prevent accidents or injuries. Additionally, the size and shape of the formwork can present challenges in terms of fitting through narrow spaces or navigating tight corners during transportation.

- Q: What are the different safety precautions to be followed during steel formwork installation?

- Some of the safety precautions to be followed during steel formwork installation include wearing appropriate personal protective equipment such as hard hats, safety glasses, and steel toe boots. Ensuring that the work area is clear of any hazards or obstructions that could pose a tripping or falling hazard. Using proper lifting techniques and equipment when handling heavy steel formwork components to prevent injuries. Adhering to proper electrical safety procedures when working with power tools or equipment near electrical sources. Following manufacturer's instructions and guidelines for the proper installation and use of steel formwork. Regularly inspecting the formwork for any signs of damage or defects and addressing them promptly. Additionally, proper training and supervision of workers should be provided to ensure they are knowledgeable about and adhere to all safety precautions.

- Q: Can steel formwork be used for high-rise construction projects?

- Yes, steel formwork can be used for high-rise construction projects. Steel formwork provides durability, strength, and stability required for the construction of tall structures. Its ability to withstand high pressures and repeated use makes it suitable for the demanding conditions of high-rise construction. Additionally, steel formwork allows for efficient and precise construction, resulting in quality finishes and faster project completion.

- Q: How does steel formwork compare to plastic formwork in terms of cost and durability?

- Steel formwork is generally more expensive than plastic formwork in terms of upfront cost. The cost of steel formwork includes the cost of material, fabrication, and transportation, which can be higher compared to plastic formwork. On the other hand, plastic formwork is relatively cheaper due to its lower material and production costs. However, when it comes to durability, steel formwork has a significant advantage. Steel is known for its strength and durability, making it capable of withstanding heavy loads and repeated use over time. It is resistant to wear and tear, deformation, and damage caused by external factors such as weather conditions or mishandling. This durability ensures that steel formwork can be reused multiple times, resulting in cost savings in the long run. Plastic formwork, while cost-effective initially, may have limitations in terms of durability. Plastic is not as strong as steel and may be prone to deformation or cracking, especially under heavy loads or if not handled properly. Although plastic formwork can still be reused multiple times, it may require more frequent replacement or repair compared to steel formwork. In summary, steel formwork may be more expensive initially but offers superior durability and longevity. Plastic formwork, on the other hand, is cheaper but may not withstand heavy loads or repeated use as effectively as steel. The choice between the two depends on the specific project requirements, budget constraints, and the expected lifespan of the formwork.

Send your message to us

Tabel Formwork system for Formwork and Scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords