new plastic formworks used in construction industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

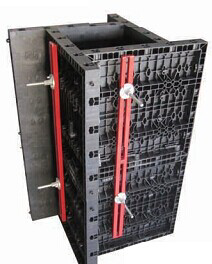

Hot rolled deformed steel framework. the peripheral board is made of FRTP plastic template and add some steel ribssupporting the panel welding a new type of industrialization combined template.which is mainl. The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. The Advantages of Plastic Formwork:

-easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

-modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

-strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

-enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

-consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

3. Images for Plastic Formwork:

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q: How long does steel frame formwork last?

- The lifespan of steel frame formwork can vary depending on factors such as maintenance, usage, and quality of the materials. However, with proper care and regular maintenance, steel frame formwork can last for several years, making it a durable and long-lasting choice for construction projects.

- Q: Can steel frame formwork be used in combination with lightweight concrete mixes?

- Yes, steel frame formwork can be used in combination with lightweight concrete mixes. The steel frame provides the necessary structural support while the lightweight concrete mix reduces the overall weight of the formwork system. This combination allows for easier handling and installation of the formwork while still maintaining the required strength and durability.

- Q: Does steel frame formwork require any additional support or bracing during the concrete pouring process?

- Typically, during the concrete pouring process, steel frame formwork necessitates additional support or bracing. This is due to the substantial pressure exerted by the weight of the wet concrete on the formwork. In the absence of sufficient support, the formwork may distort or collapse. By providing extra support or bracing, the load can be evenly distributed, guaranteeing the formwork's stability and rigidity throughout the pouring process. It is crucial to meticulously plan and design the support system to cater to the unique demands of the construction project and safeguard the formwork's safety and integrity.

- Q: Can steel frame formwork be used for residential and housing construction?

- Yes, steel frame formwork can be used for residential and housing construction. Steel frame formwork is a type of construction system that uses steel frames to support the weight of the concrete during the pouring and curing process. This formwork system is versatile and can be used for various types of construction projects, including residential and housing construction. One of the advantages of using steel frame formwork for residential and housing construction is its durability and strength. Steel frames are capable of withstanding heavy loads and provide excellent support for concrete structures. This makes them suitable for constructing residential buildings that require strong and stable structures. Furthermore, steel frame formwork is highly adaptable and can be customized to meet the specific requirements of a residential construction project. The frames can be easily adjusted and assembled to create different shapes and sizes, allowing for flexibility in design. In addition, steel frame formwork allows for faster construction compared to traditional formwork systems. The pre-fabricated steel frames can be quickly erected on-site, reducing construction time and labor costs. This is particularly advantageous for residential and housing construction projects that require fast completion to meet market demands. Moreover, steel frame formwork offers a smooth and seamless finish to concrete structures. The frames are designed to provide a uniform surface, minimizing the need for additional finishing work. This results in time and cost savings during the construction process. Overall, steel frame formwork is a suitable choice for residential and housing construction. Its durability, adaptability, and efficiency make it an ideal construction system for creating strong and aesthetically pleasing structures in a timely manner.

- Q: What are the quality control measures for steel frame formwork installation?

- Quality control measures for steel frame formwork installation involve various steps to ensure the proper installation and functioning of the formwork system. Some of the key quality control measures include: 1. Inspection of the formwork materials: Before installation, all steel frame formwork components should be inspected for any defects, damage, or corrosion. This includes checking the straightness, dimensions, and surface condition of the components. 2. Verification of formwork design: The formwork design should be verified to ensure it meets the project requirements and specifications. This involves checking the dimensions, layout, and structural stability of the formwork system. 3. Proper handling and storage: The steel frame formwork should be handled with care during transportation and storage to prevent any damage or deformation. It should be stored in a clean and dry area, away from moisture or corrosive substances. 4. Alignment and leveling: During installation, the steel frame formwork should be aligned and leveled accurately to ensure the desired shape and dimensions of the concrete structure. This can be achieved through the use of leveling devices and laser levels. 5. Secure fixing and bracing: The formwork components should be securely fixed and braced to prevent any movement or deformation during the pouring and curing of the concrete. This includes using appropriate fasteners, wedges, and clamps to ensure stability and structural integrity. 6. Regular inspection and maintenance: Throughout the construction process, regular inspections should be conducted to identify any defects, damages, or misalignments in the formwork system. Any issues should be promptly addressed and repaired to maintain the quality and safety of the installation. 7. Compliance with safety standards: Quality control measures should also include compliance with safety standards and regulations. This involves ensuring the formwork installation meets all relevant safety requirements, such as proper scaffolding, fall protection, and adequate access for workers. By implementing these quality control measures, the installation of steel frame formwork can be effectively monitored and managed, resulting in a high-quality and durable concrete structure.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier?

- When choosing a steel frame formwork supplier, there are several important factors to take into account. These factors include: 1. Quality and durability: It is crucial to select a supplier that offers high-quality and durable steel frame formwork. The formwork should be able to withstand the pressure and weight of the concrete without any deformations or failures. 2. Customization options: Different construction projects may have specific formwork dimensions and configurations. Therefore, it is essential to choose a supplier that provides customization options to meet the project's specific needs. 3. Efficiency and user-friendliness: The formwork system should be designed for easy assembly and disassembly, allowing for efficient and time-saving construction processes. It should also be user-friendly, with clear instructions and an intuitive design. 4. Availability and delivery time: Ensuring timely availability of the formwork is crucial for the smooth progress of the construction project. Therefore, it is important to select a supplier that has a reliable and efficient delivery system to ensure on-time delivery. 5. Safety features: The formwork system should have sufficient safety features to protect workers during construction. This includes non-slip surfaces, guardrails, and secure connection points. 6. Technical support and after-sales service: A reputable supplier should provide excellent technical support and after-sales service. This includes assistance with installation, troubleshooting, and maintenance of the formwork system. 7. Price and cost-effectiveness: While price should not be the sole determining factor, it is important to consider the overall cost-effectiveness of the formwork system. This includes factors such as longevity, reusability, and the supplier's ability to provide cost-saving solutions. 8. Reputation and track record: It is advisable to choose a supplier with a good reputation and a proven track record in providing high-quality steel frame formwork. Reading customer reviews and seeking recommendations can help assess a supplier's reliability and performance. By considering these key factors, construction professionals can select the most suitable steel frame formwork supplier for their project, ensuring a successful and efficient construction process.

- Q: Can steel frame formwork be used for seismic-resistant construction?

- Seismic-resistant construction can utilize steel frame formwork, which possesses the ability to withstand seismic forces and provide structural stability. Steel, being a robust and enduring material, is well-equipped to endure the impacts of earthquakes. The design of steel frame formwork systems is tailored to withstand the lateral forces and vibrations that occur during seismic events. The utilization of steel frame formwork in seismic-resistant construction brings forth a number of benefits. Firstly, it offers a remarkable level of strength and stiffness, which is pivotal in withstanding the dynamic forces exerted during an earthquake. The steel frames can be engineered to possess the necessary rigidity and strength to resist seismic loads, effectively preventing structural failure. Moreover, the assembly and disassembly of steel frame formwork systems are simple, making them particularly suitable for swift construction in areas prone to seismic activity. This facilitates an efficient construction process, reducing both time and cost, while still maintaining the required safety standards. Furthermore, steel frame formwork can be employed to create reinforced concrete structures, renowned for their ability to withstand seismic forces. By incorporating steel reinforcement bars alongside the formwork, the resulting concrete structure becomes more resistant to cracking and deformation caused by seismic activity. It is vital to note that the design and construction of the steel frame formwork system must comply with seismic design codes and regulations. This entails considering factors such as the seismic zone of the site, soil conditions, and the anticipated magnitude of earthquakes in the area. To conclude, steel frame formwork is a highly effective solution for seismic-resistant construction. Its strength, durability, and adaptability make it well-suited to withstand seismic forces and ensure the safety and stability of structures. However, it is imperative to adhere to proper design principles and comply with seismic design codes to guarantee the efficacy of the steel frame formwork system in seismic-prone regions.

- Q: When the steel frame tube structure adopts a rectangular plane, its aspect ratio should not be greater than the number of

- Bearing structure of reinforced concrete crane beam and normally open large power equipment

- Q: How does steel frame formwork contribute to the overall energy efficiency of a concrete structure?

- Steel frame formwork can contribute to the overall energy efficiency of a concrete structure in several ways. Firstly, steel is a highly durable and long-lasting material. This means that steel frame formwork can be reused multiple times, reducing the need for new formwork materials for each concrete pour. By minimizing the amount of formwork needed, steel frame formwork reduces the energy required for manufacturing and transporting new formwork components, thereby reducing the overall embodied energy of the structure. Additionally, steel frame formwork provides excellent thermal insulation properties. It helps to reduce heat loss and gain, thereby improving the energy efficiency of the concrete structure. By minimizing thermal bridging, steel frame formwork can contribute to the overall insulation performance of the building envelope, reducing the need for additional insulation materials and decreasing the energy required for heating and cooling the structure. Moreover, steel frame formwork allows for precise and accurate concrete placement. This ensures that the concrete structure is constructed with minimal wastage, reducing the amount of energy required for concrete production and transport. By optimizing the use of concrete, steel frame formwork contributes to the overall energy efficiency of the structure. Furthermore, steel frame formwork can facilitate the incorporation of energy-efficient design features into the concrete structure. For example, it enables the integration of voids and recesses for installing insulation materials, ventilation systems, or other energy-saving components. By providing the necessary flexibility in design, steel frame formwork allows for the implementation of energy-efficient strategies, such as the use of renewable energy sources or passive design techniques. In conclusion, steel frame formwork contributes to the overall energy efficiency of a concrete structure by reducing the embodied energy of the construction materials, improving thermal insulation, minimizing concrete wastage, and enabling the integration of energy-saving design features. Its durability, precision, and flexibility make it a sustainable choice that helps to optimize the energy performance of the building.

- Q: What are the considerations for selecting the appropriate formwork for different concrete placements?

- There are several factors that need to be taken into account when selecting the appropriate formwork for different concrete placements. These factors include: 1. Considering the type of concrete placement, such as vertical walls, slabs, columns, or beams, will have an impact on the formwork selection. Each type requires specific formwork systems that can accommodate the required shape and size of the concrete structure. 2. The formwork must have the ability to withstand the weight and pressure exerted by the concrete during pouring and curing. It is crucial to choose a formwork system that has the appropriate load capacity for the specific concrete placement to ensure safety and structural integrity. 3. The duration for which the formwork will be in use is another important consideration. If the formwork will be used for a short period, a temporary formwork system such as timber or plywood may be suitable. However, for long-term projects or when multiple pours are required, more durable and reusable formwork systems like steel or aluminum may be preferable. 4. The desired surface finish of the concrete also affects the choice of formwork. If a smooth and uniform finish is required, formwork materials that have a smooth surface or can be easily coated with a release agent may be necessary. On the other hand, if a textured or patterned finish is desired, formwork materials that can accommodate such designs may be needed. 5. The cost-effectiveness of the formwork materials and installation should be considered in relation to the overall project budget. Different types of formwork systems have varying costs, and it is important to select a system that is cost-effective while still meeting the project requirements. 6. The availability and accessibility of the formwork materials and equipment should also be considered. It is important to choose formwork systems that are readily available in the local market and can be easily transported and assembled on-site. 7. The environmental impact of the formwork materials is another factor to be considered. Choosing sustainable and eco-friendly options, such as formwork materials made from recycled materials or those that can be recycled after use, can contribute to a more environmentally conscious construction process. By carefully considering these factors, contractors and engineers can ensure optimal construction efficiency, safety, and quality by selecting the appropriate formwork for different concrete placements.

Send your message to us

new plastic formworks used in construction industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches