Steel Frame Formwork for Constrction with High standardized System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

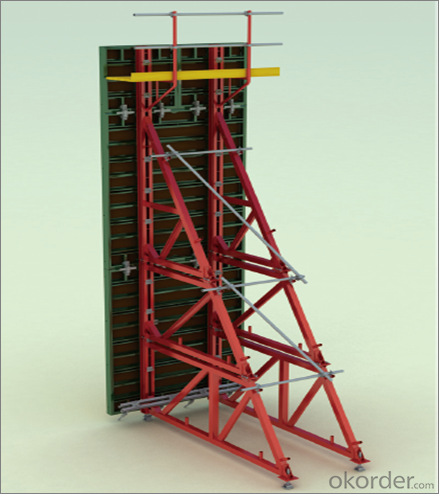

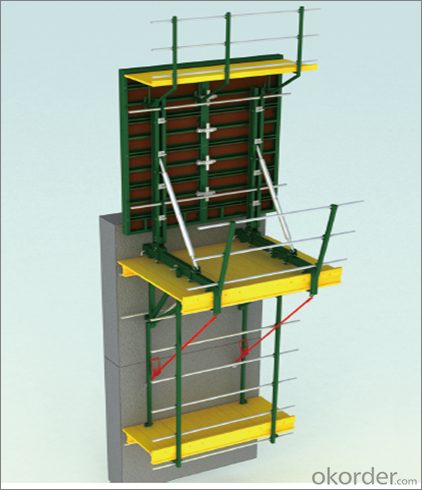

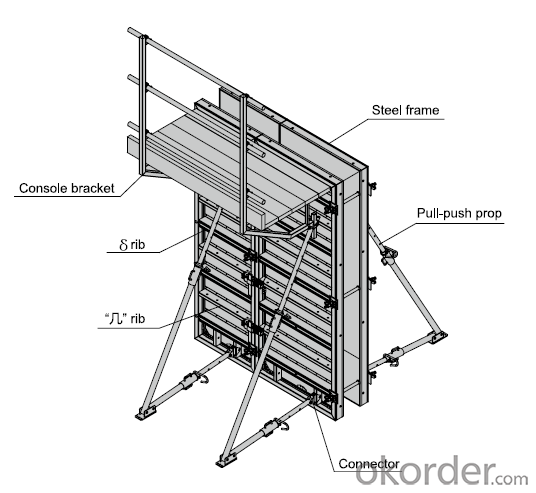

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

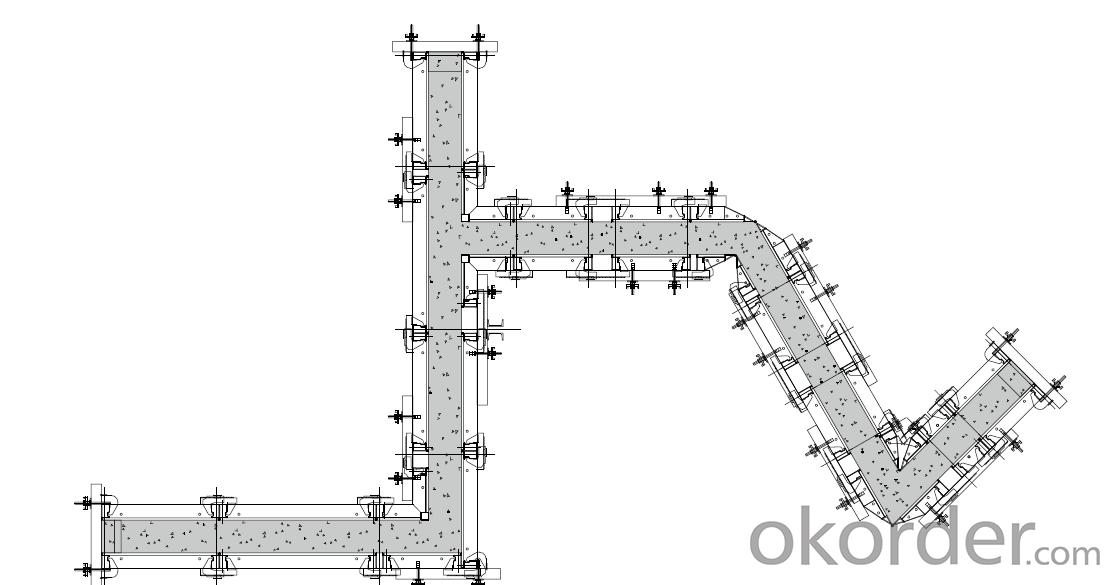

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Does steel frame formwork require any additional support or bracing during the concrete pouring process?

- Typically, during the concrete pouring process, steel frame formwork necessitates additional support or bracing. This is due to the substantial pressure exerted by the weight of the wet concrete on the formwork. In the absence of sufficient support, the formwork may distort or collapse. By providing extra support or bracing, the load can be evenly distributed, guaranteeing the formwork's stability and rigidity throughout the pouring process. It is crucial to meticulously plan and design the support system to cater to the unique demands of the construction project and safeguard the formwork's safety and integrity.

- Q: How does steel frame formwork help in reducing formwork assembly time?

- There are several ways in which formwork assembly time can be reduced with the help of steel frame formwork. To begin with, steel frame formwork is designed to be lightweight and easily adjustable, making it quick and convenient to assemble. The steel frames are typically pre-fabricated and can be easily connected together, allowing for rapid installation. This eliminates the need for complex and time-consuming assembly processes, such as cutting and shaping wooden formwork. Furthermore, steel frame formwork is highly durable and can be reused multiple times. This saves time and effort as the same frames can be used for multiple projects. In contrast, traditional wooden formwork often needs to be built from scratch for each project, increasing the overall assembly time. Moreover, steel frame formwork provides excellent stability and support, reducing the need for additional bracing and support systems. This saves time during assembly as there is no need to spend extra effort on reinforcing the formwork structure. The strong and rigid steel frames can withstand the pressure of the concrete, reducing the risk of formwork failure during the pouring process and minimizing the time spent on repairs or adjustments. Additionally, steel frame formwork allows for efficient and precise concrete pouring. The frames are designed with accurate dimensions, ensuring proper alignment of the formwork. This eliminates the need for extensive adjustments during the pouring process, saving time and reducing the risk of errors. The precise alignment also enables faster removal of the formwork after the concrete has cured, further reducing the overall assembly time. In conclusion, steel frame formwork contributes to a faster and more efficient construction process by offering a lightweight and easily adjustable design, durability for multiple uses, stability and support, and efficient concrete pouring capabilities. These features result in reduced formwork assembly time, ultimately improving overall productivity.

- Q: Can steel frame formwork be used in curved or irregular structures?

- Yes, steel frame formwork can be used in curved or irregular structures. Its flexibility and adaptability make it suitable for shaping and supporting concrete in various complex geometries.

- Q: What are the different types of accessories used in conjunction with steel frame formwork?

- In conjunction with steel frame formwork, various accessories are commonly utilized. These accessories play a vital role in guaranteeing the stability and effectiveness of the formwork system. 1. Wedge bolts are employed to connect the steel frames, ensuring a secure and tight fit that keeps the frames in place during concrete pouring. 2. Tie rods are utilized to hold the formwork panels together. They are inserted through holes in the formwork and tightened with nuts and washers. Tie rods help maintain the structural integrity of the formwork system. 3. Adjustable props provide vertical support for the formwork panels. They can be adjusted to the desired height and contribute to the stability of the formwork system. Adjustable props are particularly useful when working on uneven surfaces or when different heights are required. 4. Formwork clamps securely hold the formwork panels together, preventing any movement during the concrete pouring process. Made of steel, these clamps can be easily attached and removed, making them a convenient accessory for formwork systems. 5. Formwork spacers ensure the correct spacing between the formwork panels. They guarantee even pouring of concrete and help achieve the desired structure thickness. 6. Formwork ties are used to secure the formwork system to existing structures or other formwork systems. They provide additional stability and prevent any shifting or movement during concrete pouring. 7. Formwork corners, pre-fabricated steel components, are utilized to create corners in the formwork system. They ensure proper alignment of the formwork panels and provide a polished finish to the structure's edges. Overall, these accessories are indispensable for the successful implementation of steel frame formwork systems. They offer stability, strength, and ease of use, enhancing the efficiency and reliability of the construction process.

- Q: Can steel frame formwork be used in areas with high noise levels?

- Indeed, areas with high noise levels are compatible with the use of steel frame formwork. The durability and robustness of steel frame formwork enable it to withstand demanding working conditions, including those characterized by elevated noise levels. The exceptional strength and stability offered by the steel frame structure diminish the likelihood of vibrations and noise propagation. Moreover, it is possible to insulate the steel formwork panels or equip them with materials that diminish noise, thus further mitigating its impact. Consequently, steel frame formwork represents an appropriate alternative for construction endeavors conducted in raucous settings.

- Q: Can steel frame formwork be used for both residential and industrial flooring?

- Yes, steel frame formwork can be used for both residential and industrial flooring. Its strength and durability make it suitable for various construction applications, providing stability and support for concrete pouring and ensuring a solid foundation for both residential and industrial flooring.

- Q: Can steel frame formwork be used for pre-stressed or post-tensioned concrete structures?

- No, steel frame formwork cannot be used for pre-stressed or post-tensioned concrete structures. Pre-stressed or post-tensioned concrete structures require specialized formwork systems that can handle the high tension forces generated by the pre-stressing or post-tensioning process. Steel frame formwork is not designed to withstand these forces and may fail, leading to a potential collapse of the structure. It is essential to use formwork systems specifically designed and engineered for pre-stressed or post-tensioned concrete structures to ensure the safety and integrity of the construction project.

- Q: How does steel frame formwork contribute to better concrete curing?

- The utilization of steel frame formwork in construction involves the creation of molds using steel frames into which concrete is poured. This technique offers numerous benefits that enhance the curing of concrete. To begin with, the pouring of concrete with steel frame formwork ensures a high level of precision and stability. The steel frames are designed to be rigid and possess precise dimensions, guaranteeing that the formwork maintains its shape and does not deform during the curing process. This accuracy allows for even curing of the concrete, decreasing the likelihood of cracks or uneven surfaces. Furthermore, the utilization of steel frames allows for easy customization and flexibility in formwork design. The frames can be effortlessly adjusted and modified to accommodate various shapes and sizes of concrete structures. This adaptability ensures that the formwork aligns with the specific requirements of the project, resulting in improved concrete curing and a superior finished product. Moreover, steel frame formwork provides excellent support and reinforcement for the concrete during the curing process. The steel frames serve as a robust framework, preventing the concrete from sagging or bulging as it hardens. This support guarantees that the concrete maintains its desired shape and form, leading to a more durable and structurally sound final product. Additionally, steel frame formwork allows for efficient and convenient removal once the concrete has cured. The frames can be easily disassembled and reused for future projects, reducing waste and saving costs. This efficient removal process minimizes disruption to the curing concrete, ensuring that the curing process remains undisturbed and results in superior overall curing outcomes. In conclusion, the utilization of steel frame formwork significantly contributes to improved concrete curing through its precision, stability, support, and flexibility. By providing a high level of accuracy and strength, this construction technique ensures even curing of the concrete, resulting in a superior finished product. Additionally, the adaptability and efficient removal process offered by steel frame formwork further enhance the overall curing process and contribute to superior concrete outcomes.

- Q: Can steel frame formwork be used for both small and large scale construction projects?

- Yes, steel frame formwork can be used for both small and large scale construction projects. Steel frame formwork systems are highly versatile and can be easily adjusted and customized to accommodate projects of varying sizes and complexities. They offer excellent strength and durability, making them suitable for large-scale projects that require heavy loads and high levels of stability. Additionally, steel frame formwork provides precise and accurate results, ensuring the construction of consistent and high-quality structures. Moreover, the modular nature of steel formwork allows for easy assembly and disassembly, making it efficient for use in both small and large scale projects. Overall, steel frame formwork is a reliable and flexible solution that can be adapted to meet the requirements of any construction project, regardless of its size.

- Q: The first floor of the substation is a frame structure with a floor area of 715 square meters and a height of 4.95m. Excuse me, how much the amount of wood template? What is the quantity of steel pipe and fastener?

- Building template in accordance with 1220*2440 specifications, need 241. According to the construction experience of steel pipe vertical support 4.95M * 715 * 1.2 = 4247m

Send your message to us

Steel Frame Formwork for Constrction with High standardized System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords