Square Concrete Column Formwork AL65

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

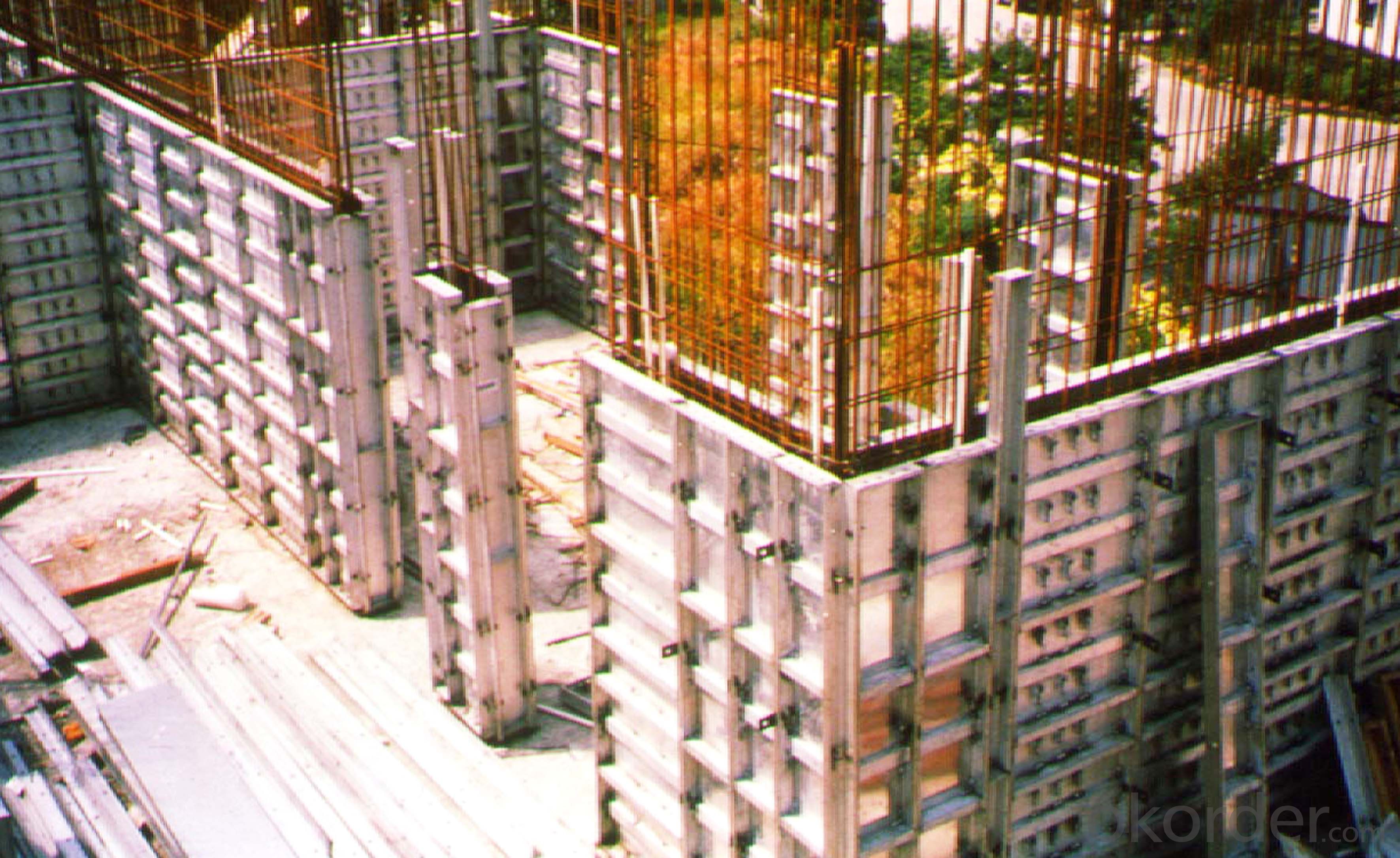

Custom SF63 Rectangle / Square

Column / Wall Construction

Adjustable Aluminum Formwork For Rectangle / Square Concrete Column

Description:

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

Competitive Advantage:

1. Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2. Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4. It is with the advantages of standard design, excellent applicability and interchangeable.

5. Simple, safe and fast.

6. No rust corrosion, easy maintenance, and high turnover rate.

Applications:

- Q: Can steel frame formwork be used for both small-scale and large-scale construction projects?

- Yes, steel frame formwork can be used for both small-scale and large-scale construction projects. The steel frame provides stability and durability, making it suitable for various project sizes. Its versatility allows for easy customization and reusability, making it a cost-effective choice for construction projects of different scales.

- Q: Does steel frame formwork require any specific training for installation?

- Yes, steel frame formwork does require specific training for installation. Steel frame formwork is a complex system that involves precise assembling and installation processes. To ensure the safety and effectiveness of the formwork, it is crucial for the installers to have the necessary knowledge and skills. Training for steel frame formwork installation typically includes learning how to read and understand technical drawings and specifications, as well as familiarizing oneself with the different components and materials used in the formwork system. Installers are trained on proper handling, lifting, and positioning of the steel frames, as well as the correct methods for connecting and securing the formwork panels and accessories. Additionally, training covers important safety procedures and measures to be followed during installation, such as the use of personal protective equipment and ensuring stability and stability of the formwork structure. It is also important to understand the load capacities and limitations of the steel frame formwork system to prevent any potential accidents or structural failures. Overall, specific training for steel frame formwork installation is essential to ensure that the formwork is installed correctly, meets the required standards and specifications, and provides a safe and stable support for concrete construction projects.

- Q: Does steel frame formwork require any specific joint sealing measures?

- Yes, steel frame formwork does require specific joint sealing measures to ensure proper concrete placement and prevent leakage. The joints should be properly sealed using appropriate sealing materials to prevent any gaps or cracks that may cause concrete leakage or affect the structural integrity of the formwork system.

- Q: Can steel frame formwork be used in areas with limited ventilation?

- Yes, steel frame formwork can be used in areas with limited ventilation. Steel frame formwork is a durable and sturdy option for construction projects, and its use is not dependent on the presence of ventilation. However, it is important to ensure that proper safety measures are in place to mitigate any potential risks associated with limited ventilation, such as providing adequate personal protective equipment for workers and monitoring air quality if necessary.

- Q: How does steel frame formwork accommodate for different concrete curing temperatures?

- Steel frame formwork is a versatile and adaptable construction technique that can effectively accommodate different concrete curing temperatures. The key lies in the inherent properties of steel, which allow it to withstand high temperatures without compromising its structural integrity. Firstly, steel has a high melting point, typically around 1370 degrees Celsius. This means that it can withstand the heat generated during the curing process, which typically involves temperatures between 10 and 30 degrees Celsius. The steel frame formwork acts as a strong and rigid structure that can support the weight of the wet concrete and resist any thermal expansion or contraction that may occur during curing. Secondly, steel has excellent thermal conductivity properties, which means that it can effectively dissipate heat and maintain a relatively stable temperature. This is particularly important in cases where the concrete curing temperature needs to be controlled or regulated, such as in cold weather conditions or when using special concrete mixtures. Furthermore, steel frame formwork can also accommodate for different concrete curing temperatures by incorporating insulation materials. Insulation can be added to the formwork to help regulate the temperature and prevent excessive heat loss or gain during the curing process. This is particularly beneficial when curing temperatures need to be maintained at a specific range for optimal strength development and durability of the concrete. In summary, steel frame formwork accommodates for different concrete curing temperatures by utilizing the inherent properties of steel, such as its high melting point and excellent thermal conductivity. It provides a strong and stable structure that can withstand the heat generated during curing, while also allowing for temperature regulation through the use of insulation materials.

- Q: Can steel frame formwork be used for both interior and exterior staircase construction?

- Yes, steel frame formwork can be used for both interior and exterior staircase construction. Steel frame formwork provides a strong and durable structure that can withstand the weight and pressure of staircases, making it suitable for use in both indoor and outdoor settings.

- Q: Is steel frame formwork fire-resistant?

- Yes, steel frame formwork is generally considered to be fire-resistant. Steel is a non-combustible material and has a high melting point, making it highly resistant to fire. Steel frame formwork is often used in construction projects where fire safety is a concern, such as high-rise buildings or structures that require additional fire protection. Additionally, steel frame formwork can be coated with fire-resistant materials or treated with fire-retardant coatings to further enhance its fire-resistant properties. However, it is important to note that the fire resistance of any structure, including steel frame formwork, depends on various factors such as the thickness and quality of materials, the design, and the overall fire safety measures implemented. Therefore, it is crucial to follow the appropriate building codes and standards to ensure the fire safety of steel frame formwork structures.

- Q: How does steel frame formwork compare to fiberglass formwork?

- Both steel frame formwork and fiberglass formwork are popular choices for construction projects, but they differ in terms of material composition, durability, and cost. To begin with, steel frame formwork is composed of steel frames and plywood panels. This combination provides excellent strength and stability, making it suitable for heavy-duty applications. The steel frames are capable of withstanding heavy loads and provide exceptional support for concrete pouring. Moreover, the plywood panels can be used multiple times in various projects due to their high reusability. On the contrary, fiberglass formwork is constructed using reinforced fiberglass panels. This material is lightweight yet durable, which offers advantages in terms of easier handling and transportation. Additionally, the fiberglass panels display resistance to water, chemicals, and UV radiation, making them ideal for projects with specific requirements such as coastal areas or corrosive environments. In terms of durability, steel frame formwork is generally regarded as more resistant to wear and tear. Steel frames have a longer lifespan and can endure rough handling and extreme weather conditions. They are also less prone to deformation and can be easily repaired or modified if necessary. While fiberglass formwork is durable, it may be more susceptible to damage if mishandled or subjected to excessive force. However, both types of formwork can have extended lifespans with proper care and maintenance. Cost is another aspect to consider when comparing steel frame formwork to fiberglass formwork. Initially, steel frame formwork tends to be more expensive as it requires the purchase of steel frames and plywood panels. However, due to its high reusability, the overall cost per project may be lower in the long run. On the other hand, fiberglass formwork is cheaper upfront but may need to be replaced more frequently, resulting in higher overall costs over time. In conclusion, steel frame formwork and fiberglass formwork each have their own advantages and disadvantages. Steel frame formwork offers strength, stability, and durability, making it suitable for heavy-duty applications. On the other hand, fiberglass formwork is lightweight, resistant to environmental factors, and initially more cost-effective. Ultimately, the choice between the two will depend on the specific project requirements, budget constraints, and expected lifespan of the formwork.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for projects with stringent quality requirements?

- When selecting the appropriate steel frame formwork system for projects with stringent quality requirements, there are several key considerations that need to be taken into account. These considerations include: 1. Material Quality: One of the most important factors to consider is the quality of the steel used in the formwork system. It is crucial to ensure that the steel is of high quality and meets the required industry standards. This ensures the durability and strength of the formwork system, which is essential for projects with stringent quality requirements. 2. Design Flexibility: The formwork system should offer a high degree of design flexibility to accommodate different project requirements. It should be able to adapt to various shapes and sizes of structures, allowing for customization and precision in construction. This flexibility ensures that the formwork system can meet the specific quality requirements of the project. 3. Ease of Assembly and Disassembly: The formwork system should be easy to assemble and disassemble, as this affects the efficiency and speed of construction. It should have a simple and intuitive design that allows for quick and hassle-free installation. This reduces the chances of errors and ensures that the formwork system can be easily adjusted or modified as needed. 4. Reusability: Another important consideration is the reusability of the formwork system. Projects with stringent quality requirements often require multiple concrete pours, and a reusable formwork system can significantly reduce costs and waste. It is important to select a system that can be easily dismantled, cleaned, and used again without compromising its structural integrity or quality. 5. Safety Features: Safety is a critical aspect of any construction project, especially those with stringent quality requirements. The formwork system should have built-in safety features to protect workers during assembly, disassembly, and concrete pouring. This includes features such as guardrails, non-slip surfaces, and secure anchoring systems. 6. Quality Assurance: The formwork system manufacturer should have a strong track record of delivering high-quality products and providing reliable technical support. It is important to choose a reputable supplier who can provide the necessary documentation and certifications to ensure compliance with quality standards. In conclusion, when selecting the appropriate steel frame formwork system for projects with stringent quality requirements, it is important to consider factors such as material quality, design flexibility, ease of assembly, reusability, safety features, and the supplier's track record. By considering these key considerations, one can ensure the selection of a formwork system that meets the highest quality standards and contributes to the successful completion of the project.

- Q: Can steel frame formwork be used in projects with limited skilled labor availability?

- Projects with limited skilled labor availability can still utilize steel frame formwork. This construction method is renowned for its durability and strength, making it suitable for a wide range of projects. Its design allows for easy assembly and disassembly, making it an ideal solution to combat the lack of skilled labor. The steel frame formwork system consists of modular panels that can be effortlessly connected and adjusted to create different shapes and sizes. This flexibility in design and construction enables adaptation to various project requirements. Furthermore, steel frame formwork is often equipped with adjustable props and braces, simplifying the construction process even further. These features empower non-skilled laborers to work effectively and efficiently, reducing the reliance on highly skilled workers. In addition, the repetitive use of steel frame formwork does not compromise its integrity, resulting in lower maintenance and replacement costs. This makes it a cost-effective choice for projects with limited skilled labor availability. In conclusion, steel frame formwork is a practical solution for projects with a shortage of skilled labor. Its ease of use, durability, and adaptability make it a viable choice to overcome the challenges posed by a lack of skilled workers.

Send your message to us

Square Concrete Column Formwork AL65

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords