Customized AL 65 Aluminum Formwork for Concrete Wall Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of AL 65 Aluminum Formwork

The whole system is made from aluminum materials. As the picture shown, every formwork unit is formed by CNBM production line. There are three special customized section bars form our standardization manufacture, and every formwork unit is welded by Robot.

AL 65 is a complete system with a full set of accessories, and can be set up flexibly according to project.

2. Main Features of AL 65 Aluminum Formwork

1.Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

2.Manual transportation can be achieved, greatly reduces the aggregate cost.

3. Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

4.It is with the advantages of standard design, excellent applicability and interchangeable.

5.Simple, safe and fast.

6.No rust corrosion, easy maintenance, and high turnover rate.

3. AL 65 Aluminum Formwork Images

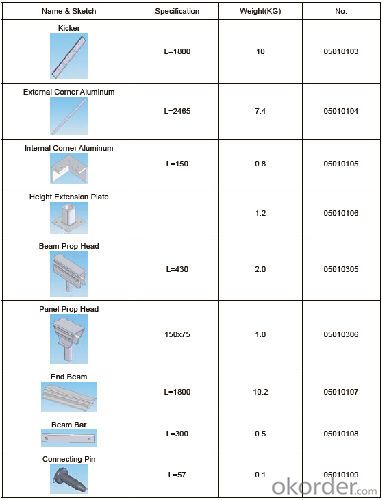

4. AL 65 Aluminum Formwork Specification

5. FAQ of AL 65 Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in AL 65 Aluminum Formwork, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of AL 65 Aluminum Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How to calculate the length of the beam, beam template area

- Is the template area, there are two times in each cross beam, then the results of the calculation of the sub beam cross-sectional area (a few minus a few) is the

- Q: Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- It is not deducted from the length to beam or column just didn't count on this side overlap, I figure out part of the coil

- Q: How to do irrigation formwork

- Pro, beam section is marked on the drawings, the beam is 200*500.

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- Because the carpenter is generally the template will be good, so that there is no reinforcement steel reinforcement

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- This option is not available in the design parametersCan only be used in the calculation of the calculation of the book or the program alone: double fastener!

- Q: More than the number of square cross-section of the beam high formwork

- According to the "dangerous method" sub project safety management of the construction quality of [2009]87, the height of more than 5m, the total construction loads greater than 10kN/m2, or the template support system concentrated line load greater than 15kN/m to prepare special construction scheme

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- A beam plate:1, according to the sum of the contact area of the template template.2. The area of the beam should be deducted.3, the beam of the template is to calculate the beam height (minus the thickness of the plate part) * net long *2 surface. The bottom die has been calculated in the bottom plate4, the bottom plate is the bottom plate of the whole plate (including the bottom of the beam), and then subtract the column area. The board only needs to calculate the bottom mold and the side die.

- Q: Beam plate with a few face template

- The beam of the beam plate is made up of 3 face plates, a bottom die and two side moulds

- Q: How to support 6m arc beam template how to set up?

- If you use a supporting beam of radian template, the bottom surface made of a whole block template (template block with good reinforcement, pouring backwater) after dismantling the entire arc shape template on the line; if the second half of the same radian can do a whole half arc template do the bottom die.

- Q: First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- The template of the beam can be completed in two or once. The two is complete, first beam bottom mould, then binding steel beam and plate, and side template; a beam bottom and side is template template and template to support end, then lashing steel beam on the template, binding after the beam falls on the beam within the template, and then tie plate reinforced.

Send your message to us

Customized AL 65 Aluminum Formwork for Concrete Wall Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords