Convenient Efficient Girder Box Formwork With Timber Beam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

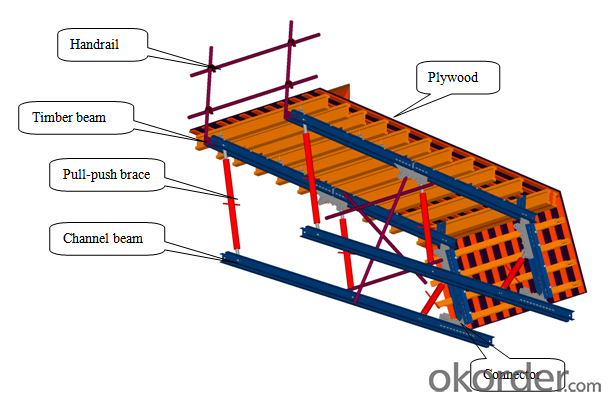

1. CMAX Girder Box Formwork System Description

GB system-A is a kind of formwork especially for the bridge floor construction.

2. Main Features of CMAX Girder Box Formwork System

- Prefabricated connection, convenient and efficient.

- Light weight but high bearing capacity.

- Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

3. CMAX Girder Box Formwork System Application

4. FAQ of CMAX Girder Box Formwork System

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:Beam plate with a few face template

- The bottom die and the two side die, the height of the side plate with the height of the plate thickness

- Q:When Liang Banzhong beam template calculation is the calculation of him in the board? Because in the calculation of engineering quantity of concrete beam by beam plate calculation. But when the template is, the book is not clear. In the calculation of the time quota template can have a beam plate.I use the Guizhou 04 quotaEspecially your last sentence, I haven't said anything yet,There is the Guizhou 04 fixed and did not say what sub beam frame beam separationAbove the beam plate is to explain the main beam, sub beam and plate, according to the calculation of beam and plate volumeThen you explain to me the frame beam is not the main beam? According to this explanation, why do you separate the frame beam

- Calculate the area between the axis, into the wall of the plate into the area of the plate, and then deduct more than 0.3 of the hole, that is, the area of the beam plate

- Q:How to calculate the amount of beam template? FiveKL2: cross section size of 0.3*0.6, thickness of the 0.12 beams, 10.9 JingchangAsk: how to calculate the amount of formwork works? How to calculate the height of support?Calculation formula

- If the border, the template area = (0.6+0.6-0.12+0.3) *10.9=1.38*10.9=15.042 square

- Q:How to support 6m arc beam template how to set up?

- 6m beam if the horizontal direction of the arc beam, when the template is located at the end of the mold and the side of the mold is a patchwork way to support the mold, the arc is not small 500mm or 1000mm together, if the arc is large 300mm or 200mm together

- Q:How to do the foundation beam template

- Construction sequence: the structure of the column to tie the tendons to the skin of the number of poles to wall masonry before the first floor on the ground has been played by the large axis of the wall body axis and the line. The surface of the base should be clean and wet. When you start the masonry, the brick should be placed and the seam width should be discharged. In the walls before the first vertical skin pole pole, skin should be marked with each skin brick and mortar joint thickness, lintel ring, position, number of rod should be set up in the skin of the building end corner, wall aspect junction and interior wall. Masonry should be up and down the wrong seam, inside and outside the lap, gray seam straight full, the level of gray seam thickness and vertical ash seam width should be controlled at around 1-1.1cm

- Q:Beam column plate template how to calculate the need to deduct what part?

- Plate under the formwork and then if there is a beam under the board, then the beam and the plate side of the area to cut off the sideDo not understand the words can continue to ask

- Q:When the main beam and secondary beam connection, calculate the area of the template is good, there is no simple method

- From the main beam to break, that is, the secondary beam axis to the axis of the long axis of the main axis of the beam to reduce the length of the beam width

- Q:There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The bottom of the beam is provided with two side edges, and the side edges are counted to the bottom of the plate

- Q:What is the formula of beam slab formwork

- The template to be installed to expand into one piece, each piece of the area is

- Q:According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Non residential frame structure of each floor area of the content of the square (excluding basement): template development area of about 2.2 to 2.6 square meters,About 0.35 cubic meters of concrete, steel bar about 50 to 60Kg.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Convenient Efficient Girder Box Formwork With Timber Beam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords