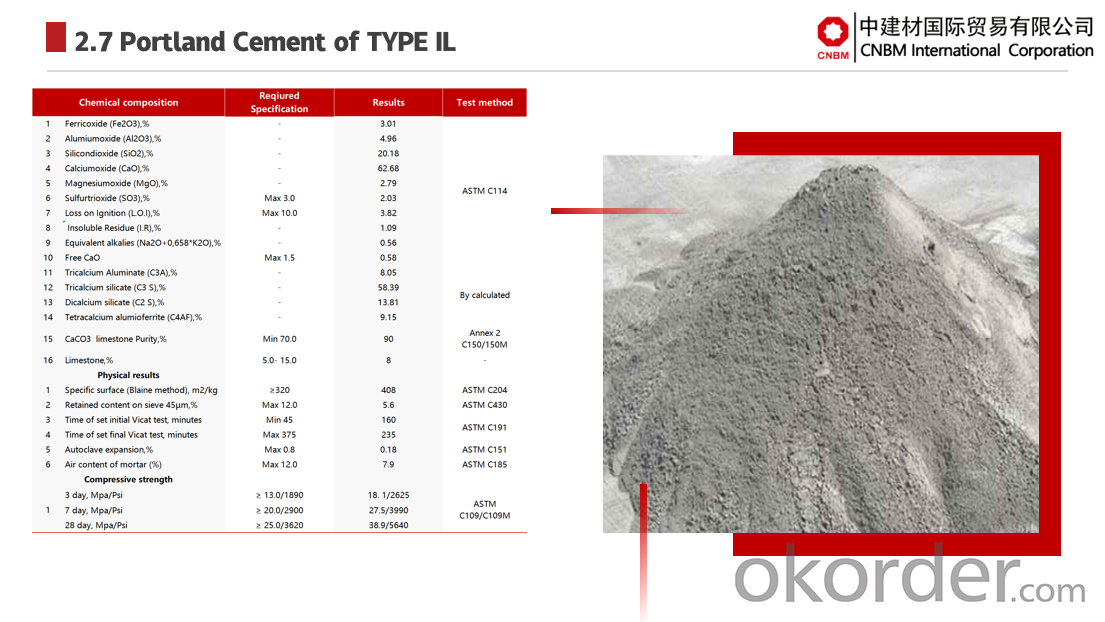

Highest quality for Portland cement of TYPE IL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: i want to put some cement in my backyard for a basketball court, is it really expensive, and about how much is it per ft.?

- It really depends on the depth of the cement. If you have want it just to play basketball the 3 inches would be perfect, howver if there are harsh weather conditions where you live then you might want to make it 4 inches. It can be expensive depending on if you are going to do it yourself or if you are going to pay some one to do it. ALso if you are going to order the cement from the company or if you are going to mix it yourself. If you pay someone it will cost you about $1500 (3 inches high for 6 yards( price may vary according to your state), it might be as high as $3000 (4 inches in depth (from dirt-surface of cement)). If you do it yourself but you order the mix from a company-->>$600-800 -- about $120 per yard(plus the labor (if you do it yourself you will still need at least 2 more people to help you since 6 yards is a lot.) If you buy the concrete mix bags from home depot you would need about 60-80 bags they are about $5 each. Then also if you intend to do it yourself you would need a lot of tools and buying them would be worse than paying someone to do it. If I were you I would just pay someone to do it 3 inches in depth. If you intend to put cars It must be at least 6 inches deep.

- Q: About us:We are factory with professional Ramp;D team and perfect after-sales service team, We are a manufacturer with national certificate, Each machine is inspected strictly before delivery. You are welcome to visit our factory anytime.

- house decoration cement render automatic rendering machine wall plastering machine cement render mix cement plastering machine sand and cement render how to cement render sand cement render cement plastering

- Q: While it was temporary cemented and good fitting, I was capable eating on it, but an extra temporary cement made my gum to reseed, so the dentist had to add an extra ceramic layer at the marginal site to cover the root, but then my bite changed and also, since then I've been experiencing pressure pain on the corrected tooth. It is not because of inflamed pulp, neither it is the gum, so is it possible that the bridge is not fitting properly now and is this correctable now?

- It sounds like you have a lot going on there, and it was a little bit difficult to follow; but hopefully I can answer your question. Once a bridge is cemented, it can't be removed without destroying it. I'm not saying it's impossible, or has never been done, but in most cases if the bridge needs to be removed, a new one would need to be made. That said, it can't really be modified (fit or structure wise) while it is in your mouth. I know you said that you didn't have a pulpal problem, but if you do end up needing a root canal, that can be done through the bridge. On the other hand, it the bridge isn't fitting right, maybe it should just be redone.

- Q: can you use cement in ceramic molds?

- I dont think so. As it dries the cement will expand and could damage or destroy the mold. Secondly I dont know how well the cement would react to a release agent in such a mold.

- Q: it's all in a 5 gallon bucket and the cement is level with the top. I plan on moving in the next 6 months so the pole needs to be mobile.

- If what you are asking is how long before I can move the bucket and pole? The answer is about two days after it was installed. Cement setting or curing is a chemical reaction and the majority of it is done within two days of mixing and pouring. It will reach approximately 85 to 90% of total cure in about one week, but for it to be totally cured could take years. Ten year old cement is harder than eight year old cement which is harder than four year old which is harder that one year old, etc. In the remodeling business, old concrete stairs and porches are a pain in the *** to remove. Most of the time if we thought that they were more than ten years old we would call in the back hoe to tear them out, other wise we used sledge hammers.

- Q: how is cement prepaed? what are the uses and different types of cement?

- I've been in exactly the same situation. We live on the edge of nowhere and can't get delivered concrete. We poured our greenhouse floor, using Portland premix cement and a mixer. Our mixer is slightly smaller than yours. We used extra water in the mix so it would stay workable longer. Bad idea! The floor did fine until the first winter. It then split, chipped cracked and, well, you get the picture. We ended up redoing it. The second time we divided the floor into three sections. Each section had its own small 3/8 rebar web placed 2 above ground in a 4 floor. We supported the web by driving 10 pieces of 3/8 rebar into the ground and wire to hold the web to them. Lastly, on the sides where the adjoining sections would go, we used 1 x 6 pieces of redwood. We drilled them and ran rebar through to the web – leaving 2' sticking out for attaching the new sections. That piece sticking out was attached to the next section's rebar web. It has been there for several years now, and has no cracks at all. Our temperatures range from 105°F in summer to -40°F in winter. I put a link in to show how to determine how many cubic yards of concrete you'll need. Good luck!

- Q: How come i can kickflip on grass but not on cement?

- DO NOT do anything that would prevent the blocks from moving. They expand and contract constantly, so if you prevent movement, they will crack and it would look even worse. DO NOT use caulking, or cement. That just makes the sidewalk blocks crack, then the problem comes right back. Try some boiling water. Make sure that you do so on a hot day so that the blocks don't crack. For a temperairy job, if you have a Weed-whiper/Weed-hacker, then just use that to do it. Iff the sidewalk blocks are evenly spaced apart with at least 0.5cm of space, then that would work. If the sidewalk blocks are tight against eachother, the only way that I see fit is to get on your hands and knees and start scrubing that dirt away. It takes a lot of work, but the results are great! Then, if you can find an edger [A machine that makes a small-ish gap between the sidewalk and grass] just take back the grass so that no dirt gets back for a long while. Doing it by hand, is better because you get more of a gap, then the time will be greater before you have to do it again.

- Q: whats the differenc`e between concrete and cement?

- Concrete is a mix of gravel, sand, and cement; the exact proportion is governed by the desired end use. Often there are some other additivies depending upon the exact end use. Cement, usually portland cement is one component of concrete. I could go on and on about the chemical nature of portland cement, how it is made, why it does what it does as well as discuss what it does but that would require a lot more space than this forum allowes and a lot more ambition than I have to type it all in.

- Q: please can someone help me??

- Here are my TOP TEN responses to describing porridge... as thick as WET cement and as bland as: 10. cardboard 9. a rice cake 8. wax fruit 7. elevator music 6. George Bush's personality 5. a glass of water 4. a bowl of sand 3. my 9th grade History teacher 2. a cotton ball 1. well, ...wet cement

- Q: It's already cured for about 36 hours. Is there something i can do? Someone mentioned something about Hydraulic cement. ????????

- There's no such thing as evening out cement once it's cured. It has to be removed and redone. Don't pay the contractor, and have him rip up the whole thing and start from scratch. His mistake... you shouldn't have to pay for it. NOTE: Take digital pictures in case you need to take legal action. A tip: place a newspaper from that day on the ground when taking a picture so that you can prove the date of the pictures.

Send your message to us

Highest quality for Portland cement of TYPE IL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords