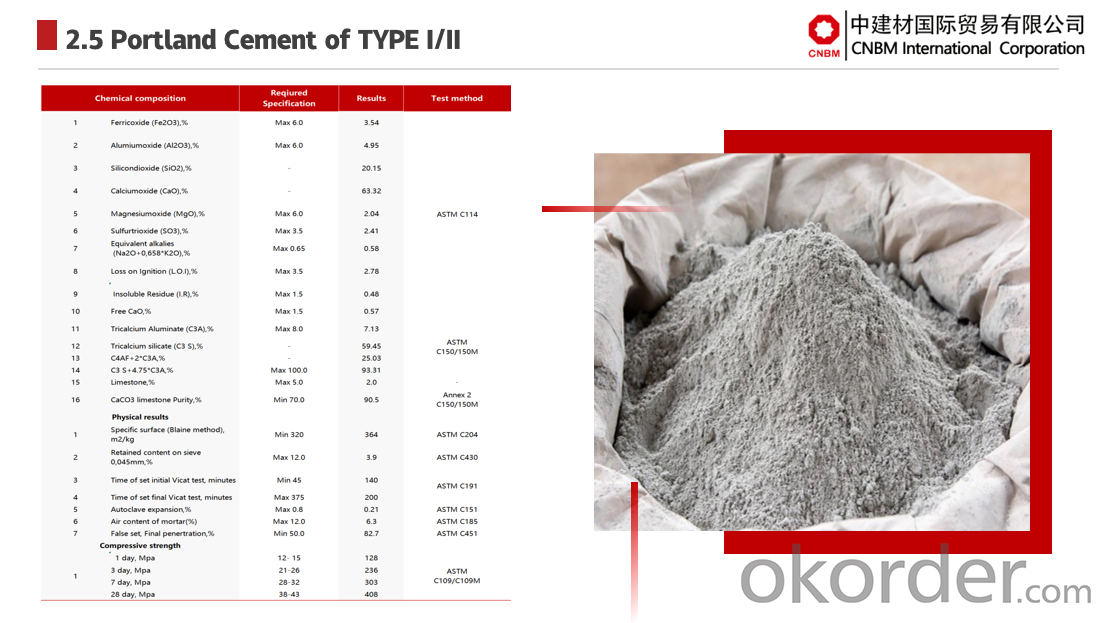

Highest quality for Portland cement TYPE I/II

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: My book is set in a medieval ish setting, and I need to know whether cement is an acceptable flooring for a cellar, or if stone should be used? Apparently cement has been used since the Ancient Egyptians, but I don't know if that's a good term for it. Is there an early term I could use? Or should i just use stone?

- The word cement traces to the Romans, who used the term 'opus caementicium' to describe masonry resembling modern concrete that was made from crushed rock with burnt lime as binder. Cement comes from Latin caementum 'chips of stone'; cement is an ingredient of concrete. With this background information, and sicce your book has a medieval-ish setting, I would suggest using the term caementum when you describe the cellar flooring.

- Q: I saw bags of concrete bags of cement in Home Depot. What's the difference?

- yes, they are pretty much the same but, idk why didn't you ask when you were there

- Q: what is sound proof cement made out of?

- I don't think it exists. Cement is typically used as a binding agent for concrete. Because it is very dense, it transmits sound vibrations thru it, and would not be sound proof. There are sound attenuating walls made of concrete, but they still allow some sound to pass thru. The only sound-proof place is inside an anechoic chamber!!!

- Q: Are they immortal or something?

- Ummm... you don't get burns when touching wet cement...

- Q: They just put it on me, it worked just fine, then it came off on command without a trace (back in the 80's.) But I'm wondering what it chemically actually is.

- It's called, simply enough, dental cement, but chemically, it's usually zinc phosphate. Sometimes the zinc phosphate is mixed with polyacrylic acid, creating polycarboxylate cement. and in response to the additional detail: I don't know how the zinc phosphate cement is removed, but for the carboxylate, they use organic acids (especially citric, I think).

- Q: I've read that you can repaint it if you decide you want a different color, but if you like the color can you just leave it or do you have to repaint it every few years, like wood siding?

- Unless you buy the cement board siding already painted you will need to paint it. As for painting it every few years like wood....the paint will hold up much better on the cement board.

- Q: I want use cement board 1/2quot; under my toilet and then use carpet to put over that. Is that a good idea? What are my options?

- yup you can use cement board on floors, walls, ceilings... anywhere you think moisture may be a problem. as for putting carpet on it, you can, but it wouldnt be my first choice, just because carpet can hold onto moisture and possibly encourage mold. if you like carpet, go ahead, but watch the moisture. otherwise, use tile or lino, and use area rugs.

- Q: Concrete, Asphalt 140 pounds/cubic footConcrete, Gravel 150 pounds/cubic footConcrete, Limestone w/Portland 148 pounds/cubic footCement, Portland 94 pounds/cubic footCement, mortar 135 pounds/cubic footCement, slurry 90 pounds/cubic foot

- First, cement is the calcium sulfate binder which (with the addition of water and admixtures) becomes concrete for construction. Gravel for the construction of Hoover Dam was mined nearby, so the likely answer from those given would be the second.

- Q: My aviary just has dirt on the bottom late today i noticed a mouse hole!!What would be the best material to put in the bottom? Rocks? Cement etc.Also, My bird ( galah ) never goes to the bottom of the cage, what is a good way to get her to do this?

- you should think of putting a layer of cement on the bottom .Its easy to keep clean and you wont get anything digging through.Also you can put sand over the cement ,this will help absorb the droppings of the bird then you can just sweep it out and replace with new sand. To get the bird to go to the ground put some toys down.They are curious and will investigate.

- Q: Pls Provide Top 10 interview question about cement marketing?Raj_bajaj2050@yahoo.in

- dude your list is all screwed up it should be 1. Jordan 2. Kobe 3. Larry Bird 4. Kareem Abdul Jabbar 5. Dwayne Wade

Send your message to us

Highest quality for Portland cement TYPE I/II

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords