Floor Tiles/Standard Size Polished Glazed Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day other m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1-Full polished glazed cement tiles

2-W.a: E<0.1%

3-60X60 CM

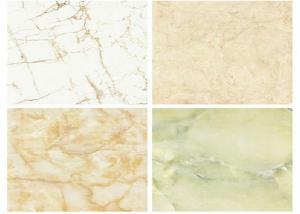

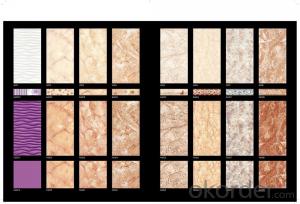

4-style:marble look design

5-Manufactory derict supply

product Description

Size |

600X600mm(23"X23"inch) 800X800(34X34"inch) |

Color |

Grays/yellows,brawns,grays;Red; White etc |

Water -absorption rate |

E<0.1% |

Abrasion strength |

PEI4,5 |

Thickness: |

10mm+/-0.2 |

Quality |

Class A |

Usage |

Home,office building,hotel;projects , flooring;and indoor or outdoor wall tile |

Packing Information

| Size | PCS/CTN | KG/CTN | CTN/PLT | PLT/FCL |

600X600(23"X23"inch) | 4 | 30 | 40 | 20 |

| 800X800(34X34"inch) | 3 | 45 | 28 | 20 |

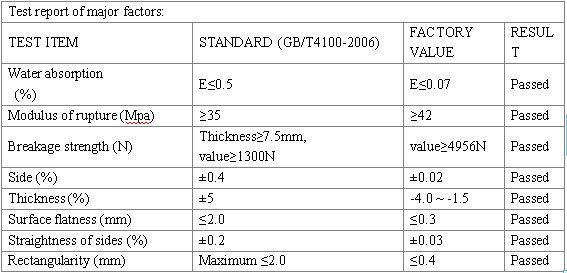

Test report

- Q: I am replacing a kitchen floor with tile. When I ripped up the existing floor there was plywood in great shape. Do I really need to lay cement board down beofre tiling? What could happen if I dont?

- Had to scroll all the way to the bottom to find someone (Miss T) who bothered to consider what you were tiling over. If you are on a slab, no need for cement board. If you are on a raised foundation you need to make the substrate rigid enough to resist flexing. There are several ways to do this-another layer of ply (stagger seams with respect to the existing layer), Hardibacker, Wonderboard, etc. I generally use 2 1/2 inch screws to secure the existing substrate to the joists first regardless of what I'm installing over it. I occasionally sister 2 x 4s to the existing joists if the floor is particularly bouncy, or add cross bracing. I've never had a call back on any of my tile work (going back 25 plus years) Thinset doesn't stick to wood? install mesh? Where are these people coming from. Mesh is NEVER used on a floor and it wasn't used 50-100 years ago either. Only on walls and counter tops and thinset adheres to plywood just fine.

- Q: There was a fire and the beam burned at the end that rest on the cement block. I want it to be solid when the new beam goes on.

- You did not give much info on the cement block just the beam. How big of a block are we talking about? What is the construction of the cement block? 2,000 psi? 2500 psi? How intense was the fire? Most fires will not hurt cement blocks. How much weight is this beam holding? After you take the burnt beam off you can make a better assessment on the cement block. I'm willing to bet my last dollar, it will hold up a new beam fine. Good Luck!

- Q: x barrels of this concrete, the number of barrells of cement used isA) x/5B) x/4C) xD) 4xE) 1/5xPlease explain.

- The answer is A x/5 To make the concrete you need to have cement and sand. Say you have 1 barrel of cement, then to make the proper concrete mix you would need 4 barrels of sand (the 1:4 ratio of cement to sand) this would make 5 barrels of your concrete. So now we know that for every 5 barrels of concrete you need 1 (or 5/5) of cement, and thusly for every x barrels of concrete you would need x/5 barrels of cement. Hope This Helps.

- Q: WHATS THE DIFEREANCE BETWEEN CEMENT, AND CONCRETE?

- Cement is the powder made from limestone, clay and gypsum that is the binder for making concrete. Concrete is the product of mixing cement with sand and/or gravel and water. Sidewalks, bridges and buildings are concrete, not cement.

- Q: I cant figure out what consistency to mix this cement at. I am pouring it for a shower but need to know how much water to add. I would REALLY like an exact calculation, like 20 parts cement to 1 part water for example. Anybody know? Thank you! Again, this is for a shower......

- finally a mixture that wealthy will shrink and crack. it fairly is only too annoying and as a result too brittle for stucco - which correct could be approximately a similar density because of the fact the substrate (if brick) or rather mushy if on cord lath so as that it may amplify and settlement with temperature ameliorations and not crack. we've a house inbuilt 1890, and those days (18 months in the past) had approximately 4 hundred sq. ft of undesirable stucco got rid of and altered, approximately 100s.f. on mushy brick, the rest on new stainless-steel cord lath and beads. The brick application became 3:a million sand-to-portland cement, the 300s.f. final became 4:a million sand to Portland Cement. the two had admixtures extra in to the actual-coat (producer's colored mixture) for colour, solid adhesion and adaptability. the two have been actual 3-coat applications which blanketed soaking the bricks previous to installation so as that the stucco cured correct. so some distance, curiously great and shows no cracks, separation or splitting.

- Q: Say a person was in a large tub and they filled the tub with wet cement and it was to be filled right up to the persons shoulders leaving his neck and head sticking out? Like after the block of cement hardens? Would the person die?just curious.

- DEATH happens,dear. Crushing the chest kills. Haven't you ever picked up even a small sack of *dry*cement?

- Q: and also does the cement have an affect on the water quality, such as ph, hardness...etc?and also if i do build it out of cement, do i still have to put down a pond liner?and also does anyone have any advice, or info on building a pond out of cement?THANK YOU

- Cement-by which I presume you mean concrete, is fine for building a pond. It Will have an effect on the ph of the water. Cement is alkaline so the lime content would be very harmful to fish and aquatic life in the short term. Eventually it would become neutral but you would need to waterproof it with something anyrate which would keep the water away from contact with the cement. You can use bitumen which you paint on or a sheet of strong plastic is often enough.. Dig out the shape you want first and then shovel the concrete into it but if the sides are steep then you will have to make the concrete very dry to prevent the concrete running back into the bottom. You can always then give a thin coat of wetter cement to the sides later if you prefer

- Q: i xcan do an ollie perfect on grass, but not on cementPlease give tips on how i can be able to do it on cement!!!!!HELP!

- Okay, ollieing on cement is not much different at all... its just your fear of falling and getting hurt. Heres what you have to do, When you ollie lean forward alot more than what you normally would in grass, second when you jump try to keep your legs level dont leave one higher than the other... this usually results in doing a split. Third when you land bend your knees dont keep them straight or your gonna bust your ***.....1.Lean Forward.2.Feet are Level.3.Bend Knees When Landing.

- Q: If u set a car battery on the ground(dirt,cement,asphalt,etc) will it lose its charge?

- oh yea the concrete will

- Q: It is cheaper to build a cement house than wood?

- The inexperienced woodworker and the very experienced person will be able to do these projects without any difficulty OKorder Each and every one of the thousands woodworking plans and projects which are available are so well written so that even if you've never tried Woodworking before, or if you have 2 left hands, you would find woodworking a breeze

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2006 |

| Annual Output Value | Above US$15 million |

| Main Markets | Asia, Middle East |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese;Arabic |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Floor Tiles/Standard Size Polished Glazed Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day other m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords