Floor Tile for Building Project Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

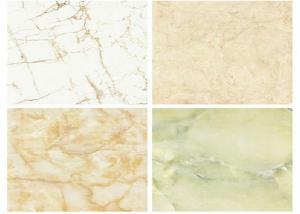

Floor Tile For Building Project Cement Tile

1.Glazed cement tile

2.W.A:lass than 0.5%

3.600x600,300x600,300x300mm

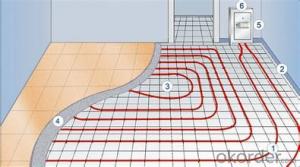

4.used:floor,wall

5.glossy glaze

Details of Floor tile for building project cement tile

Item No | P60621 |

Material | porcelain |

Finish | 3d printing |

Water absorption | 0.5 |

Size |

600x600.600x300,300x300,etc |

Thickness | about 9.5mm |

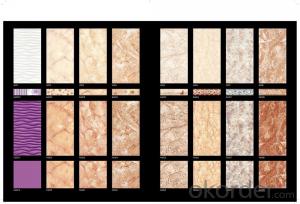

Color | white,pink,green and many color are available |

Packing | carton with wooden pallet,seaworthy |

usage | floor and wall |

Tenique | Glazed Tiles |

Test report:

Packing details:

size | pcs/ctn | kg/ctn | sqm/ ctn | ctn/plt |

300x300 | 11 | 22 | 0.99 | 62 |

300x600 | 8 | 32 | 1.44 | 40 |

600x600 | 4 | 32 | 1.44 | 40 |

- Q: i need help hopefully someone can answer before wensday

- A cement is a binder, a substance that sets and hardens independently, and can bind other materials together. it was made from crushed rock with burnt lime as binder. Cement (as in Portland type cements) is made by heating limestone to 1450 degrees C, then grinding the result into fine powder and adding a small amount of clay. When mixed with sand, stones, or other aggregates, the result is concrete. Cement hardens by hydration, absorption of water, and not by drying. Chemical Formula for cement i think its 3CaO SiO2 Go to this link... this may help you to find you a better answer elearning.vtu.ac.in/Programme%2016/ENotes/ConcreteTechnology/Unit1-RVR/Unit1-L2-RVR.pdf

- Q: is there a sealer product for a diy person...or what else is available... it is a laundry room in the basement in a 40 yr. old raised ranch house..no water problems...the surface has small pitting in one area..we have considered flash coating and vinyl flooring and click flooring tiles...looking for a diy solution....

- paint it with concrete floor paint like in a garage

- Q: How Fireproof Is Cement? I Tryed To Make A Mold For Metal Casting Out Of It, But It Fell To Pieces. Did I Make It Wrong, Or Is Cement No Good For 1100?C+ ??

- It depends on how long it has been there, and if removing the section would make the driveway unusable. If it has been there a long time, you are not likely to be able to do anything about it. There are several doctrines that would make this so. If you want to get a portion removed, i would talk to them first. If they get a lawyer, you will be fighting this for a long time, so it is best to just try diplomacy first. Whatever you do, don't go out there with a jackhammer and start breaking concrete. This is a great way to end up in bigger trouble. Before you start, you will need an accurate survey as well.

- Q: As there are many types of cement, i want basic types of cement

- Type 1 - Normal portland cement. Type 1 is a general use cement. Type 2 - Is used for structures in water or soil containing moderate amounts of sulfate, or when heat build-up is a concern. Type 3 - High early strength. Used when high strength are desired at very early periods. Type 4 - Low heat portland cement. Used where the amount and rate of heat generation must be kept to a minimum. Type 5 - Sulfate resistant portland cement. Used where the water or soil is high in alkali.

- Q: I was wondering if bees can go through cement?Like a cement wall or something.I've heard they can go through wood.

- No bees in my part of the world can go through concrete, or cement or wood, wood is used to make bee hives, (for honey bees) Carpenter bees will chew a hole in some woods (mostly soft woods) I have never seen a Carpenter bee chew a hole in a live or growing tree, The wood generaly has to be cut wood like a park bench or such.

- Q: 325 ordinary home improvement cement is not to 50 kg people to sell? Questions added: Also, fill the gap between the white cement, buy two or three kilograms, people will sell it? More

- Under normal circumstances, the cement is bought by bag. If you just want a little bit, find someone else to a little, will give, or to protect the helium 氦 send a large number of money. White cement, is on the buy ...

- Q: It has four cement walls but the bad thing is there is a water pump in the pit, so area is limited inside, like an area 5X5, and it has the floor of the house as it's quot;coverquot;.

- If you're in tornado land chances are something was built in the home you live in to protect from the weather. If that's all there is it'll most certainly prove to work.

- Q: I want to lay cement all along the bottom of the whole fence , keeping the fence from touching the grass and also keeping my dogs from digging out ?? I just dont know how thick the footer should be or how wide .. Anyone ??

- If you are looking nice ideas for woodworking i can suggest you to check here ( woodworkingplans.kyma ) It's perfect if you are just starting out or if you're a seasoned carpenter. you will like it for sure! It has almost 20.000 woodworking plans and you have a CAD/DWG software to view and edit the plans. You have step-by-step instructions with photos and high quality blueprints and schematics. If you are a beginner this is the easiest way to start your woodworking projects, and if you already have experience you can anyway find a lot of interesting ideas!

- Q: My parents have a family of life size cement deer that they want me to bronze. They figured I could find instructions on the internet but so far I'm not having a lot of luck. Does anyone know of a resource that can help me out? (I'm used to painting ceramics but never a bronze finish before -- and never anything that big!)

- There are various paints that might be used. However cement can be a problem when it comes to paint,because it is acidic.There is process called acid washing or maybe it's acid staining a process for applying color to existing cement ,primarily floors, that you might look into. Google cement colorants, cement stains etc. Most of the information available on the net applies to industrial application,floor coloring ,architectural applications. Working with cement can be hard on the hands so use some rubber gloves.

- Q: i'm replacing the old wall in my tub with hardibacker. can i screw it on the tub lip? coz the instructions said that it should be screwed or nailed 3/8quot; from the eges.

- Don't place it over the lip. Your cement board, or greenboard for that matter, should rest on top of the lip. Then you fill in the gap with thinset and mesh tape. That way the wall doesn't bulge out at the bottom on all three sides making the tiling harder to do.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2006 |

| Annual Output Value | Above US$15 million |

| Main Markets | Asia, Middle East |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese;Arabic |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Floor Tile for Building Project Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords