Wholely Assembled Box Girder Template Made in China

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

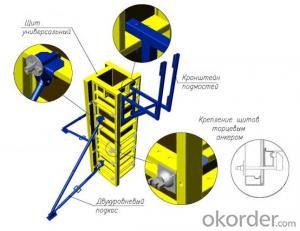

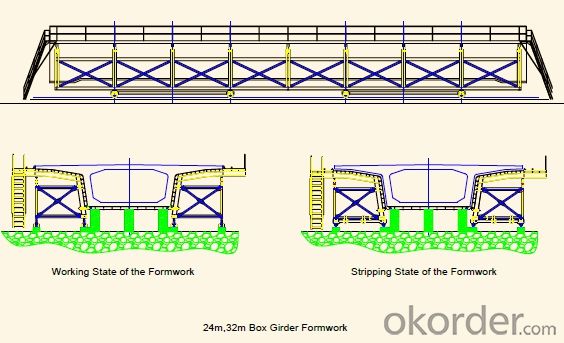

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: What is the foundation beam template

- I was in the study of this problem, it should be the construction is not based on beam design has been explained, but the quota is a little different, the beam bottom cushion or other basis should be the beam, it should be suspended under the general frame or beam. The difference is that the two side support and the three side support. Usually the explanation is still looking for evidence.

- Q: What is a large volume template? How much is the cross section of the beam, belonging to the large volume template?

- The above construction total load of more than 10kN/m2, or concentrated line load greater than 15kN/m template support system that belongs to the template, if you do not consider other loads, considering the single weight, according to concrete 25000KG/m3 calculation, then the beam section area of 0.4m2 belongs to the template, such as 400*1000, 300*1350, 500*800 etc.. Central line loads can be calculated in similar ways.

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Multi storey residential building structure of each floor area of square meters of content: the template to expand the area of about 2.4 to 2.9 square meters, concrete about 0.42 LiAbout 55 meters, reinforced to 65Kg.Basement floor area per square metre of content: the template to expand the area of about 2.4 to 3 square meters, concrete about 0.8 to 1.1 cubic meters,Steel bar about 125 to 170Kg.

- Q: When the main beam and secondary beam connection, calculate the area of the template is good, there is no simple method

- The landlord is complicated. When the beam is calculated, the main girder is calculated, and the axis is the length of the axis

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- A beam plate:1, according to the sum of the contact area of the template template.2. The area of the beam should be deducted.3, the beam of the template is to calculate the beam height (minus the thickness of the plate part) * net long *2 surface. The bottom die has been calculated in the bottom plate4, the bottom plate is the bottom plate of the whole plate (including the bottom of the beam), and then subtract the column area. The board only needs to calculate the bottom mold and the side die.

- Q: Seeking beam, plate template engineering quantity

- The second beam template (bottom area +2* side area): (2.6*3- wall thickness) * (0.2+ (0.4-0.12) *2) *2-0.2*0.25*4 [the main beam and the secondary beam transfer area] -0.2*0.4*2*4 [the main beam and secondary beam transfer area]

- Q: How to support 6m arc beam template how to set up?

- After setting out in accordance with graphics support ah. If the curvature is large, it can be approximated by linear segmentation.

- Q: I would like to ask the three sides of the template is calculated on the surface of which is the three? Novice do not understand thank you

- The utility model relates to a three surface template beam (both sides of the beam and the bottom surface of the beam), and the other is a two side formwork beam (two sides of the beam)

- Q: What are the main composition of the beam template

- D> suspended beam formwork support composite structure A> roof formwork support composite structure consists of main beam (main dragon's back), auxiliary beam (vice dragon), support rod, cross bar composed of B> shear wall formwork supporting structure.

- Q: What is the demolition order of the construction template

- 3 the demolition of multilayer floor pillar shall be carried out according to the following requirements: when the upper floor slab is pouring concrete, the next floor slabThe pillar shall not be removed, then the next floor of a live, can only be removed part of the span is 4M or above 4M Xiajun should retain the brace beam, pillar spacing shall not be greater than 3M.

Send your message to us

Wholely Assembled Box Girder Template Made in China

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords