Anti-arch Adjustment Box Girder Template Made in China

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

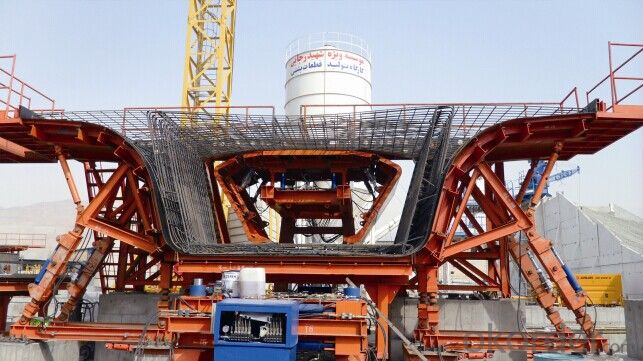

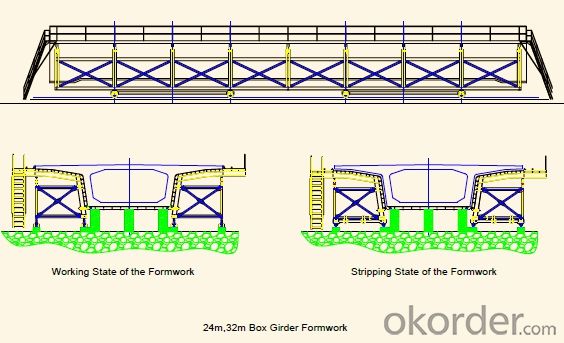

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- Remove from the ends of beams began to load, is Liang Hezhu nodes under pure shear, a shear deformation from the middle split beam gradually remove support, after the load is gradually increased, the shear in the support under the protection of gradually increasing load, small impact.

- Q: Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- . Calculate the volume of the cushion should be very good, where the beam on the cushion ah, as to how the layout drawings will be.

- Q: What kind of frame beam formwork

- The frame beam (KL) is a beam which is connected with the frame column (KZ), or both ends are connected with the shear wall, but the span height ratio is not less than 5. In the structural design, there is another point of view for the frame beam, that is, the beam that needs to participate in the earthquake resistance. With the rise of high-rise buildings, the pure frame structure is becoming more and more rare, but the shear wall structure of the frame beam is mainly involved in the seismic beam.

- Q: For example, a beam 200*400, length 5000Plate thickness 1005000*5000The area of the template is1, (0.2+0.3*2) *5+5*52, 0.3*2*5+5*5Which is right

- The beam of the template is to calculate the beam height (minus the plate thickness of the part) * net long *2 surface. The bottom die has been calculated in the bottom plate.Louzhu certainly not familiar with the construction site, as long as the scene to see how the template is placed.

- Q: More than the number of square cross-section of the beam high formwork

- For the height of more than 8m, the total load is greater than 15kN/m2, or the central line load greater than 20kN/m of the template support system needs to organize expert demonstration".

- Q: There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The bottom of the beam is provided with two side edges, and the side edges are counted to the bottom of the plate

- Q: Beam column plate template how to calculate the need to deduct what part?

- A method is relatively simple and practicalThe calculation formula of the first column is the circumference multiplied by the height of the unit is M2

- Q: Beam plate with a few face template

- The bottom die and the two side die, the height of the side plate with the height of the plate thickness

- Q: A set of 50 m T beam steel template weight

- Fifty m T beam steel formwork, a complete set of general must contain a set of side beams in the beam half

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- According to the calculation of the expansion area, the height of support according to the bottom elevation

Send your message to us

Anti-arch Adjustment Box Girder Template Made in China

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords