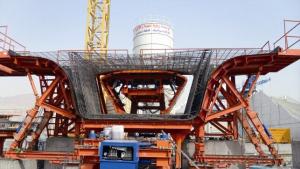

Construction Slab U type concrete precast Beam shape Steel Formwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

U Type Beam formwork

Product Introduction:

With the rapid development of urban rail transit project, the U-Beam is widely used in viaduct road. Currently, U-Beam is one of the most innovative viaduct that was used in urban rail transport. It have the advantages of noise-reduction good effect, low building height, high space utilization and good appearance.

With the progress of technology, construction method changes from cast-in-place to precast hoisting. Use double crane lifting or gantry crane lifting to hoisting the U-Beam.

Specification:

Precast U-Beam formwork structure: outer side formwork, inner formwork, bottom formwork, support lead screw, JACK, work platform, Vibrator, crawling ladder, blanking plate etc.

Main products covers:

U-shaped beam

Segmental beam

Climb mold

Integrated pipe gallery

Automatic Prefabrication culvert

Shaped pier

T-beam

Alien template

Applied formwork Project:

Our products capacity:

More than 3 state grade certificates

More than 40 patents

More than 10 series main products

More than 10 government and project awards

WORKSHOP & EQUIPMENT:

- Q: What is the foundation beam template

- The template based beam should be the construction is not based on beam design has been explained, but the quota is a little different, the beam bottom cushion or other basis should be the beam, it should be suspended under the general frame or beam. The difference is that the two side support and the three side support.

- Q: Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- The connection between the column and the beam and the place where the beam is connected with the beam does not need to be deducted from the area.

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- Calculation of anti slide of fasteners? the sliding bearing capacity of the fastener is calculated in accordance with the following formula (5.2.5):R = Rc

- Q: The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- The board side mode *2 is the circumference of the board (minus column protruding part) multiplied by the thickness of the plate 0.1m.

- Q: The area of the beam template = (both sides of the high and low beam) * beam lengthWhat do you mean by the two words in the brackets?

- Beam: beam length multiplied by the end of the beam and 2 times the length of both sides, the beam length to the side of the column, the wall side, the second beam to the main beam side, the outer part of the calculation of the center line, according to the calculation of the internal part of the net long linePlate: the column, beam, 0.3 square meters outside the hole area

- Q: How to do the foundation beam template

- Construction sequence: the structure of the column to tie the tendons to the skin of the number of poles to wall masonry before the first floor on the ground has been played by the large axis of the wall body axis and the line. The surface of the base should be clean and wet. When you start the masonry, the brick should be placed and the seam width should be discharged. In the walls before the first vertical skin pole pole, skin should be marked with each skin brick and mortar joint thickness, lintel ring, position, number of rod should be set up in the skin of the building end corner, wall aspect junction and interior wall. Masonry should be up and down the wrong seam, inside and outside the lap, gray seam straight full, the level of gray seam thickness and vertical ash seam width should be controlled at around 1-1.1cm

- Q: When there is a beam plate template, the beam can not be added to the template?

- Beam template and foundation beam template to separate sets of fixed!

- Q: How to calculate the intersection of rectangular column and beam

- Beam:(1): the length of beam to column connection, the length of the beam to column side; girder transfer, beam to beam side. The beam length at the door (window) wide hole net length calculation. According to the center line, wall beam wall is calculated according to the net line.(2) the area of the beam connecting part is not deducted, and the area of the beam head is not increased(3) the area of the beam pad is incorporated into the beam

- Q: How to control the elevation of the beam bottom and the axis position

- The design of the middle arch ratio is higher than the span of the span of 1--2 thousandths of 2. A template, according to the control point set square.

- Q: What is the demolition order of the construction template

- Template removal sequence:General is the first non load bearing template, but bearing template; the first side plate, the back plate. Follow the line after the demolition, the demolition of non weight-bearing parts, the demolition of the load-bearing parts and the principle of top-down,

Send your message to us

Construction Slab U type concrete precast Beam shape Steel Formwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords