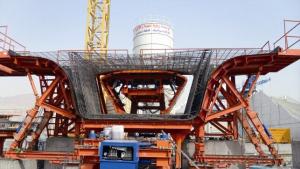

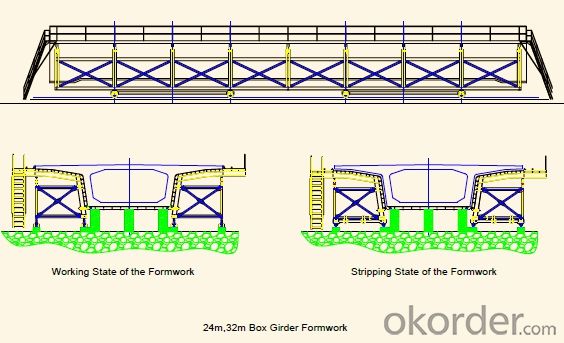

Concrete Pre-faricated Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- The connection between the column and the beam and the place where the beam is connected with the beam does not need to be deducted from the area.

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- Because the carpenter is generally the template will be good, so that there is no reinforcement steel reinforcement

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Shear wall structure (such as small high-rise, high-rise) per square meter area of the content of the building: the template to expand the area of about 3.3 to 3.6 square meters,About 0.5 cubic meters of concrete, steel bar about 60 to 75Kg.

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- A beam plate:1, according to the sum of the contact area of the template template.2. The area of the beam should be deducted.3, the beam of the template is to calculate the beam height (minus the thickness of the plate part) * net long *2 surface. The bottom die has been calculated in the bottom plate4, the bottom plate is the bottom plate of the whole plate (including the bottom of the beam), and then subtract the column area. The board only needs to calculate the bottom mold and the side die.

- Q: How to support 6m arc beam template how to set up?

- 6m beam if the horizontal direction of the arc beam, when the template is located at the end of the mold and the side of the mold is a patchwork way to support the mold, the arc is not small 500mm or 1000mm together, if the arc is large 300mm or 200mm together

- Q: I would like to ask the three sides of the template is calculated on the surface of which is the three? Novice do not understand thank you

- The utility model relates to a three surface template beam (both sides of the beam and the bottom surface of the beam), and the other is a two side formwork beam (two sides of the beam)

- Q: A set of 50 m T beam steel template weight

- Fifty m T beam steel formwork, a complete set of general must contain a set of side beams in the beam half

- Q: How to calculate the intersection of rectangular column and beam

- Plate and beam plate:(1) the calculation of the area of beam and plate according to the area of beam and plate;(2): high beam plate girders according to the amount of height of sheet thickness calculation;(3) a long beam plate girders: beam to column connection, the length of the beam to column side; girder transfer, beam to beam side.(4) the calculation of the area of the plate and column cap without beam(5) the area of the beam connection is not deducted, and the beam head area is not increased

- Q: I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- High formwork concrete beams are usually large in size, gravity load, plan people sometimes use 50 x 100 (width * height) wood brace, called Liang Xiaoliang, a thin concrete slab gravity load is less, with 30 * 80 mu Fang, challenge the small beam. According to the different rib beam floor plan, good people, they try to use the same specifications of the wooden architrave, there is no Liang Xiaoliang, small plate beam, just calculate book Liang Xiaoliang, trabecular plate.

- Q: What are the main composition of the beam template

- A> roof formwork support structure B> shear wall structure of formwork C> column formwork support structure

Send your message to us

Concrete Pre-faricated Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords