Assembly Precision Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

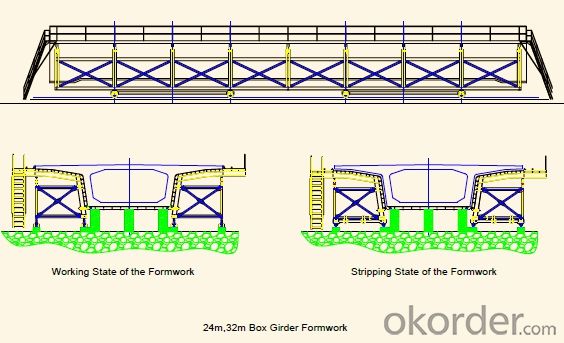

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to put the beam formwork in concrete structure

- When the carpenter die down from the ceiling! To determine! But you need to check it regularly! Not everyone does it by the rules!

- Q: The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- Slowing down the negative effect of uneven settlement. There are difference and ring beam (beam) foundation beam mainly links, enhance the level of rigidity, sometimes used as underfill supporting beam wall, without considering the seismic effect.

- Q: What is a large volume template? How much is the cross section of the beam, belonging to the large volume template?

- According to the "dangerous method" sub project safety management of the construction quality of [2009]87, the height of more than 5m, the total construction loads greater than 10kN/m2, or the template support system concentrated line load greater than 15kN/m to prepare special construction scheme

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- So in the form of the frame up binding, binding with a crane to lift the steel beam, the following overhead with the wood out of the beam of steel on the template

- Q: Calculate the beam template when you want to reduce the thickness of the plate

- Now the general calculation of the template area is the concrete contact surface is positive, the template thickness to be deducted.

- Q: Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q: The calculation formula of the beam column for the construction of the concrete and the use of the template area of the detailed point of the best thank you

- No formula, the calculation of the volume of concrete, the calculation of the area of the template, this is no formula can be applied, as long as the understanding of the drawings is slowly

- Q: I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- High formwork concrete beams are usually large in size, gravity load, plan people sometimes use 50 x 100 (width * height) wood brace, called Liang Xiaoliang, a thin concrete slab gravity load is less, with 30 * 80 mu Fang, challenge the small beam. According to the different rib beam floor plan, good people, they try to use the same specifications of the wooden architrave, there is no Liang Xiaoliang, small plate beam, just calculate book Liang Xiaoliang, trabecular plate.

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- According to the calculation of the expansion area, the height of support according to the bottom elevation

- Q: How to control the elevation of the beam bottom and the axis position

- Above the control points on the scaffold steel pipe before supporting formwork

Send your message to us

Assembly Precision Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords