Roof Template Timber Beam Formwork System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Roof Template Timber Beam Formwork System

FA-TNOR system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, it is good choice for slab construction.

2. Main Features of Roof Template Timber Beam Formwork System

1. Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover. High Efficient Ring-Lock Scaffolding Table System / Scaffold Formwork

2. Easy operation

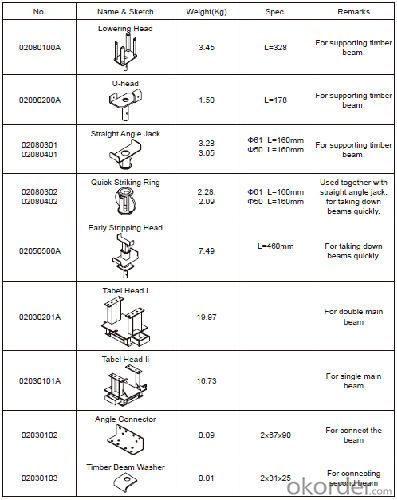

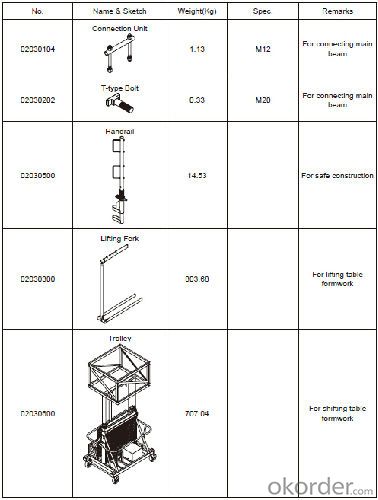

The formwork is composed of plywood, timber beam, channel beam, connectors and ring-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

3. Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffolding; the scaffolding can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

4. Mature system with specific tools for removing

We afford trolley for FA-TNOR system, trolley is especially for shifting table formwork from the slab, it guarantees easy operation and safe removing.

3. Roof Template Timber Beam Formwork System Images

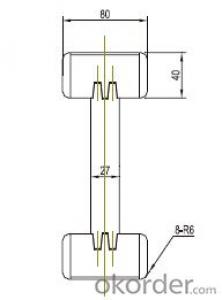

4. Roof Template Timber Beam Formwork System Specification

5. FAQ of Roof Template Timber Beam Formwork System

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Roof Template Timber Beam Formwork System, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Roof Template Timber Beam Formwork System, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How to put the beam formwork in concrete structure

- By way of hanging on the board, you do not want to put a line for you!

- Q: The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- The ground beam (patand) agreement is commonly known as the foundation beam, which has the characteristics of closed, and the structure of the column into a seismic system,

- Q: Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- Calculation of foundation beam! When the cap is to be deducted beam

- Q: I only see the span is greater than 4M of the beam arch height is 1/1000~3/1000, if that is 5m, 8m, 12M, 16m and even assuming 20m, the supply is only 1/1000~3/1000????

- 4.4.6 on the span of not less than 4m of the beam, the plate, the height of the template arch should be the beam, plate span 1/1000~3/1000.

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Multi storey residential building structure of each floor area of square meters of content: the template to expand the area of about 2.4 to 2.9 square meters, concrete about 0.42 LiAbout 55 meters, reinforced to 65Kg.Basement floor area per square metre of content: the template to expand the area of about 2.4 to 3 square meters, concrete about 0.8 to 1.1 cubic meters,Steel bar about 125 to 170Kg.

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- Calculation of anti slide of fasteners? the sliding bearing capacity of the fastener is calculated in accordance with the following formula (5.2.5):R = Rc

- Q: The formula for the calculation of beam, concrete and brick

- The area of the template (= the height of the side of the beam and the bottom of the beam)The cast-in-place concrete beams (including foundation beam) template, according to three surface width multiplied by the beam length, measured in square meters.

- Q: How to do the foundation beam template

- Construction sequence: the structure of the column to tie the tendons to the skin of the number of poles to wall masonry before the first floor on the ground has been played by the large axis of the wall body axis and the line. The surface of the base should be clean and wet. When you start the masonry, the brick should be placed and the seam width should be discharged. In the walls before the first vertical skin pole pole, skin should be marked with each skin brick and mortar joint thickness, lintel ring, position, number of rod should be set up in the skin of the building end corner, wall aspect junction and interior wall. Masonry should be up and down the wrong seam, inside and outside the lap, gray seam straight full, the level of gray seam thickness and vertical ash seam width should be controlled at around 1-1.1cm

- Q: What is the demolition order of the construction template

- 1 demolition vertical face template, should be carried out from top to bottom; demolition of the larger span of the beam pillar, should start from the middle, respectively, to the two ends.2 demolition of beams and floor bottom mold, should loosen the wedge or lower bracket, then by block or patch removal

- Q: First of all, what are the construction of the structure of the template, such as walls, columns, beams and ladders, which is the structure of the first installation of the template after the installation of steel? Ten

- On the contrary, the beam plate is the first template, tied after the reinforcement, because the beam plate is flat, the first binding steel, do you want to let the first suspension? That's not going to collapse

Send your message to us

Roof Template Timber Beam Formwork System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords