Timber Scaffolding Singapore

Timber Scaffolding Singapore Related Searches

Mobile Scaffold Singapore Scaffolding Canada Collapsible Scaffolding Scaffolding For Sale Toronto Lighting Supplier Singapore Scaffolding Roof Scaffolding Access Scaffolding Bars Scaffold Netting Scafolding Northern Tool Scaffolding Laminated Plywood Singapore Modular Scaffolding Cement Board Singapore Drywall Partition Singapore Scaffolding Certification Scaffolding Sales Uk Catwalk Scaffolding Automatic Door Singapore Pipe Scaffolding Drywall Scaffolding Scaffolding For Sale Philippines Wedge Lock Scaffolding Waterproofing Membrane Singapore Advanced Scaffolding Used Scaffolding For Sale Toronto Scaffolding In India Solid Sawn Pine Scaffold Boards Scaffolding Wheels Movable Scaffolding PlatformTimber Scaffolding Singapore Supplier & Manufacturer from China

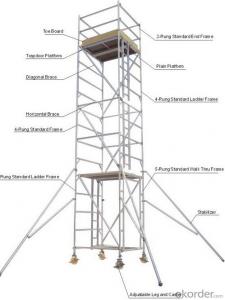

Timber Scaffolding Singapore is a popular choice for construction projects due to its durability and cost-effectiveness. This type of scaffolding is made from high-quality timber, which provides excellent support and stability for various construction tasks. It is widely used in the construction industry for tasks such as bricklaying, painting, and general maintenance work, making it an essential tool for any building project.Timber Scaffolding Singapore is highly sought after for its versatility and adaptability to different construction needs. It can be easily assembled and disassembled, allowing for quick setup and breakdown on various job sites. This product is also known for its ability to withstand harsh weather conditions, making it suitable for both indoor and outdoor use. Its sturdy structure and long-lasting nature make it a preferred choice for contractors and construction companies alike.

Okorder.com is a leading wholesale supplier of Timber Scaffolding Singapore, boasting a large inventory to cater to the demands of the construction industry. With a commitment to providing high-quality products at competitive prices, Okorder.com ensures that customers receive the best value for their investment. By offering a wide range of timber scaffolding options, Okorder.com is able to meet the diverse needs of their clients, making it a trusted partner for construction projects in Singapore and beyond.

Hot Products