Revolving Dismantled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

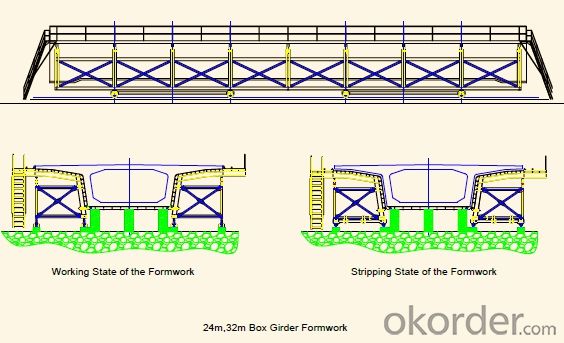

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- When the formwork of the beam is not removed, the load of the beam is evenly distributed. If the two ends of the span from the demolition of the words, the load is borne by the beam at both ends of the column and the template in the cross, when the removal of the template in the cross, the beam is likely to produce cracks and damage. Only from the cross to the ends of the removal, the load is evenly distributed to the ends of the column, the beam will not be destroyed.

- Q: What is the wire mesh in front of the foundation beam

- Beams are reinforced, how to put into the template? How can we ensure that the concrete does not flow out? Wire netting is the best way

- Q: When the height of the beam is small, the beam of the beam is tied up on the top of the beam formwork; when the beam height is large, the steel bar of the beam is bound on the bottom of the beam. What do you mean?

- When the beam height is large, the beam of the steel beam in the bottom of the bundle, which means that the beam of the overall weight of steel, in the Liang Dimo binding, and then seal the side template, and then pouring concrete

- Q: Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Multi storey residential building structure of each floor area of square meters of content: the template to expand the area of about 2.4 to 2.9 square meters, concrete about 0.42 LiAbout 55 meters, reinforced to 65Kg.Basement floor area per square metre of content: the template to expand the area of about 2.4 to 3 square meters, concrete about 0.8 to 1.1 cubic meters,Steel bar about 125 to 170Kg.

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- Note: when the right angle fastener tightening torque of 40--65N.m, test shows that the single fastener will slide in the 12kN under the load, the sliding bearing capacity of desirable 8.0kN; double fastener will slide in the 20kN under the load, the sliding bearing capacity to be 12.0kN.Note: the above values are experimental values! Take a look at your calculation results and this value to meet the double anti sliding bearing capacity can be!

- Q: Beam plate template is composed of the bottom template and what

- Rectangle, F=1, A is the length of the bottom edge, B is high..... So, S1S2, S3,..., one by one. The sum of the above Si is the total area. The amount of template engineering is required

- Q: Seeking beam, plate template engineering quantity

- Main girder template (bottom area +2* side area): (2.4*3- wall thickness) * (0.25+ (0.4-0.12) *2) *2--0.25*0.4*2*4 secondary beam area

- Q: When there is a beam plate template, the beam can not be added to the template?

- SureBeam template, template, template based beam section is different

- Q: What is the demolition order of the construction template

- Template removal sequence:General is the first non load bearing template, but bearing template; the first side plate, the back plate. Follow the line after the demolition, the demolition of non weight-bearing parts, the demolition of the load-bearing parts and the principle of top-down,

Send your message to us

Revolving Dismantled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords