Wholely Assembled Box Girder Template Made in China with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

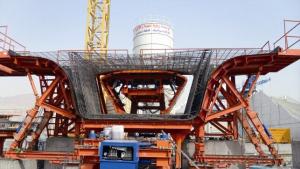

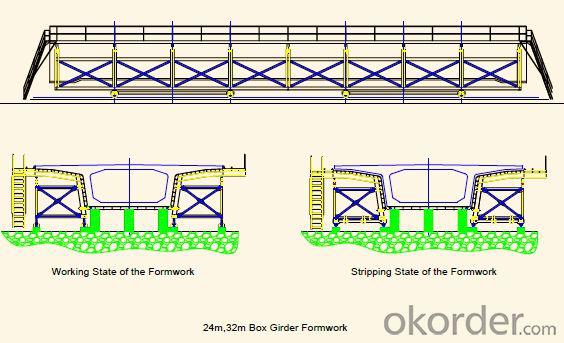

Wholely Assembled Box Girder

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

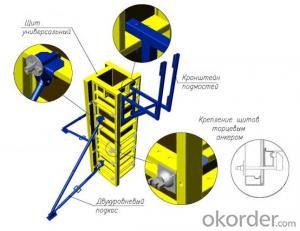

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q: How to calculate the length of the beam, beam template area

- The two cross KL76, distance of each cross axis of the pillar width is Jingchang (beam by beam, high *2+ Liang Kuan)

- Q: Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- The calculation of the net area on both sides of the formwork. Cushion volume should be very good

- Q: What is the meaning of the steel beam overhead on the top of the beam formwork

- Because the carpenter is generally the template will be good, so that there is no reinforcement steel reinforcement

- Q: How to calculate the amount of beam template? FiveKL2: cross section size of 0.3*0.6, thickness of the 0.12 beams, 10.9 JingchangAsk: how to calculate the amount of formwork works? How to calculate the height of support?Calculation formula

- If it is in the middle, the template area = (0.6-0.12) *2+0.3] squareThe height of support is calculated according to the height of beam bottom

- Q: Which part of the middle beam and side beam in the T beam template? Thank you

- Sandwiched in the middle for the [beam] and close to the abutment of a span [edge] the rest of the [medium]

- Q: The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- The board side mode *2 is the circumference of the board (minus column protruding part) multiplied by the thickness of the plate 0.1m.

- Q: More than the number of square cross-section of the beam high formwork

- For the height of more than 8m, the total load is greater than 15kN/m2, or the central line load greater than 20kN/m of the template support system needs to organize expert demonstration".

- Q: What is the formula of beam slab formwork

- The template to be installed to expand into one piece, each piece of the area is

- Q: The main floor beam template installation should pay attention to what?

- 2) install the side formwork of the beam and drill the side of the side of the side of the pull screw hole after the additional diagonal reinforcement.3 check the beam center line, elevation, section size, adjacent beam column template connection is fixed.4) after the beam and plate steel reinforcement is finished, the 1/2 pairs of the beam height are put on the pull screw, and the outer part of the pull screw is coated with a hard PVC casing, and the screw spacing is 1000mm.

- Q: 10-3 degrees of weather, cast in situ floor and girder formwork can be demolished a few days? 25 days enough? There's a wall on the beam.

- When the bottom formwork of the reinforced concrete slab with a span of 5m is removed, the concrete strength should be greater than or equal to 75% of the standard value of concrete cube compressive strength.

Send your message to us

Wholely Assembled Box Girder Template Made in China with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords