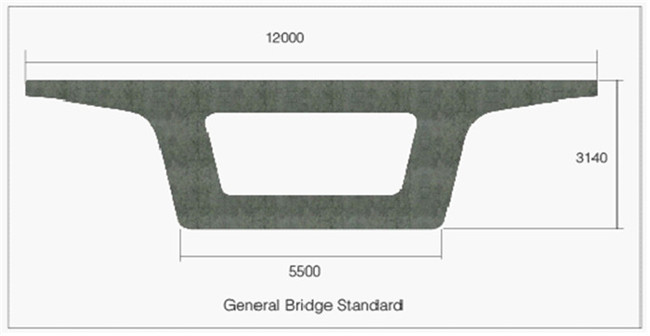

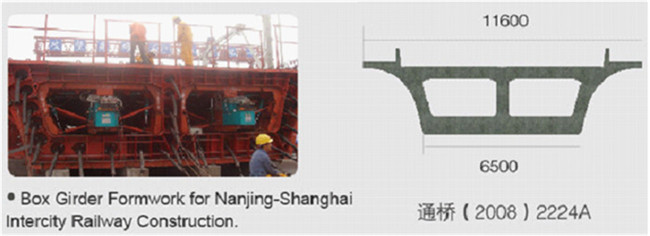

Hydraulic Box Girder Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Features:

①The formwork travels through main girder supported by inner form, and adopts double-line hydraulic lifting system to achieve high precision, compact structure, whole contraction and easy demoulding.

②Easy operation, integrally lifting and dragging inner form into formwork, can achieve whole demoulding after concrete pouring without any manual dismantling, greatly reduces labor intensity and improves working efficiency.

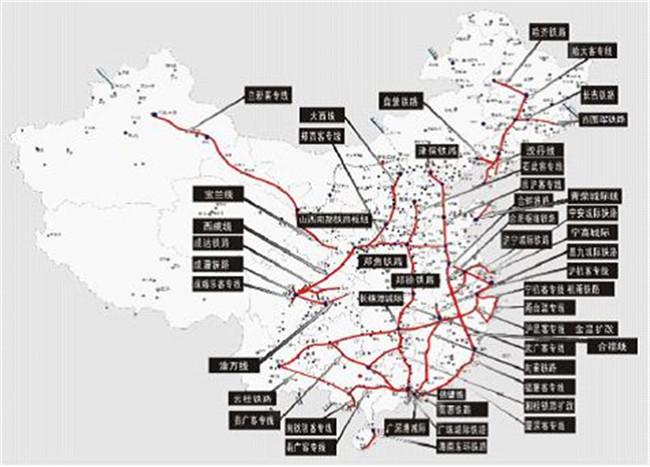

③Until the end of 2013, nearly 2,000 sets of box girder formwork we manufactured are used in over 50 domestic high-speed railway, highway, intercity railway and subway construction.

Domestic Sales Chart of Box Girder Formwork:

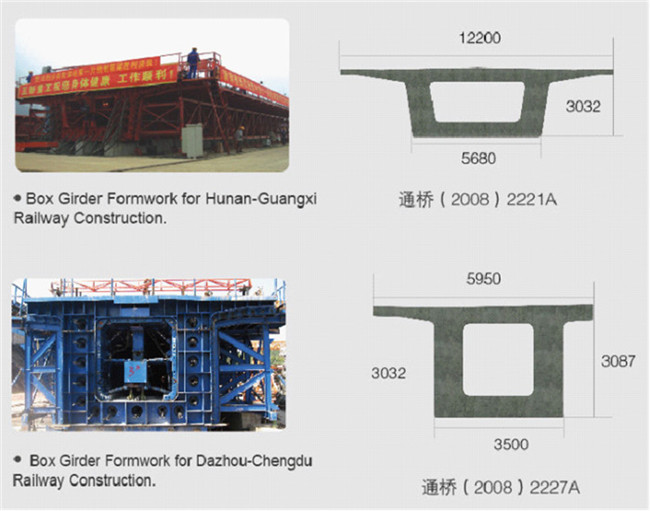

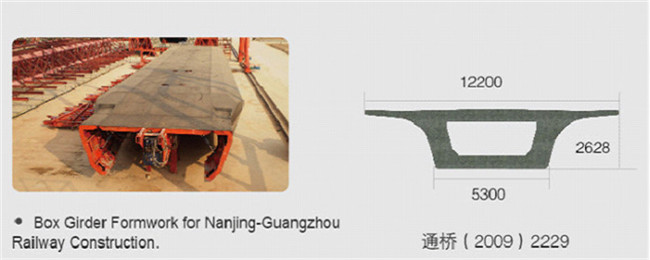

Projects:

- Q: How to calculate the length of the beam, beam template area

- Is the template area, there are two times in each cross beam, then the results of the calculation of the sub beam cross-sectional area (a few minus a few) is the

- Q: The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- The calculation of the formwork quantity of the beam is not needed to calculate the bottom of the beam

- Q: Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q: The formwork support is a beam template which is connected with both sides of the vertical rod and the force at the bottom of the beam and the force of the vertical wire rod which is arranged below the transverse beam at the bottom of the beam

- This option is not available in the design parametersCan only be used in the calculation of the calculation of the book or the program alone: double fastener!

- Q: Beam column plate template how to calculate the need to deduct what part?

- Plate under the formwork and then if there is a beam under the board, then the beam and the plate side of the area to cut off the sideDo not understand the words can continue to ask

- Q: How to do the foundation beam template

- The main body of each layer of concrete using fixed pump delivery. Before pouring, it is necessary to clear the debris in the template and advance the wet mode, the concrete vibration needs to be timely, coherent, and shall not leak slurry, reinforcement intensive place need to strengthen the vibration, to ensure the concrete density. Concrete vibrator should try to avoid the direct vibration of the template, to prevent the expansion of the joints at the seams, so as to set up the site to inspect the quality of the template.Wall column concrete pouring in place, to prevent the beam, the plate when pouring overflow phenomenon affect the appearance quality, the wall column concrete pouring should be carried out in time for two times to ensure that the structure section size is correct, the founder does not distort deformation.

- Q: Seeking beam, plate template engineering quantity

- Main girder template (bottom area +2* side area): (2.4*3- wall thickness) * (0.25+ (0.4-0.12) *2) *2--0.25*0.4*2*4 secondary beam area

- Q: The calculation formula of the beam column for the construction of the concrete and the use of the template area of the detailed point of the best thank you

- Calculation of the contact area between the template and concrete, there is no formula, there can be no formula

- Q: I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- Plate is a template, bamboo plywood, wood plywood. The small beam is directly supporting formwork wood architrave, there are several kinds of pine, the section size of 30 x 80, 40 x 80, 50 x 100. Support is wood brace steel bar, also called beam

- Q: What is the demolition order of the construction template

- 1 demolition vertical face template, should be carried out from top to bottom; demolition of the larger span of the beam pillar, should start from the middle, respectively, to the two ends.2 demolition of beams and floor bottom mold, should loosen the wedge or lower bracket, then by block or patch removal

Send your message to us

Hydraulic Box Girder Formwork

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords