Box Girder Steel Formwork System

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

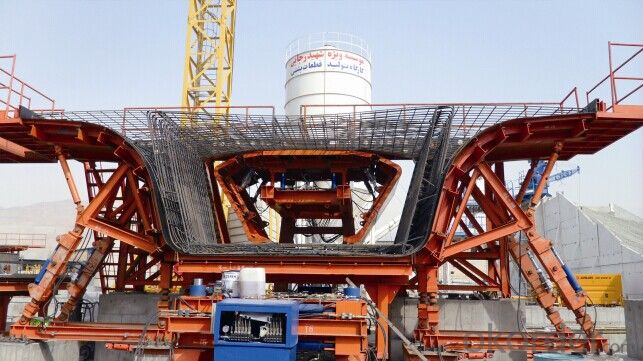

1. Structure of Box Girder Steel Formwork System

A vertical support system widely used in construction of slab or shoring. The prop has simple structure; it is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.A vertical support system widely used in construction of slab or shoring. The prop has simple structure; it is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.

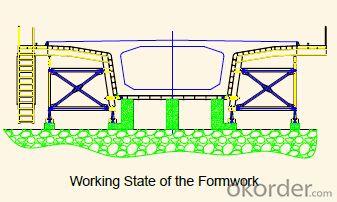

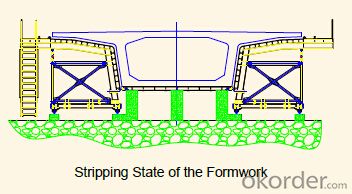

External formwork of 32/24 meters post-tensioning concrete prefabricated box girder is divided into sliding mode and rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency of formwork closure.The side formwork unit is mainly 6 meters, the design of the structure is compact and reasonable with beautiful and smooth appearance.

2. Main Features of Box Girder Steel Formwork System

A) All the edges of external formwork panels for the box girder have been milled, which ensure the assembly precision to avoid the leakage of the concrete.

B) The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment.

C) The bulkhead is designed to envelop the side-form,which can be wholly assembled, making the removal, installation and adjustment much easier.

3. Box Girder Steel Formwork System Images

4. Box Girder Steel Formwork System Specification

5. FAQ of Operating Platform

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Box Girder Steel Formwork System, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Box Girder Steel Formwork System, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- . Calculate the volume of the cushion should be very good, where the beam on the cushion ah, as to how the layout drawings will be.

- Q: How to calculate the amount of beam template? FiveKL2: cross section size of 0.3*0.6, thickness of the 0.12 beams, 10.9 JingchangAsk: how to calculate the amount of formwork works? How to calculate the height of support?Calculation formula

- According to the calculation of the expansion area, the height of support according to the bottom elevation

- Q: Beam plate template is composed of the bottom template and what

- The template will be installed to expand into one piece, each piece of the area is Si=F*A*B, the formula, F coefficient

- Q: The area of the beam template = (both sides of the high and low beam) * beam lengthWhat do you mean by the two words in the brackets?

- Wall: exterior wall from the upper surface of the floor to the upper surface of the floor, the inner wall is considered to the upper floor (beam) under the surface, within 0.3 square meters of the area of the hole is not deducted, do not increase the side wall template, the use of large formwork when the hole is not deducted

- Q: There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The general situation is calculated according to the contact area between the concrete and the template

- Q: When the main beam and secondary beam connection, calculate the area of the template is good, there is no simple method

- From the main beam to break, that is, the secondary beam axis to the axis of the long axis of the main axis of the beam to reduce the length of the beam width

- Q: Beam plate with a few face template

- There are beams and plates, the 3 words behind the content should be said board...

- Q: I would like to ask the three sides of the template is calculated on the surface of which is the three? Novice do not understand thank you

- Beam template is to calculate three sides, is the beam of the two sides with the bottom of the beam

- Q: A set of 50 m T beam steel template weight

- Fifty m T beam steel formwork, a complete set of general must contain a set of side beams in the beam half

- Q: I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- Directly subjected to loading template called small beam beam beam emerged called bear small load. The landlord asked the name of small square steel beam, 80 by 80 Fang Mu called Liang Xialiang; 70 by 70 Fang Mu challenge of small beam pipe is under the plate beam. In fact, there is no strict definition.By the way, there is no 48 by the steel pipe of this specification, recommended (suitable for use) is 48.3 x 3.6 Q235 material straight welded steel pipe, the market does not sell.

Send your message to us

Box Girder Steel Formwork System

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords