Building tunnel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

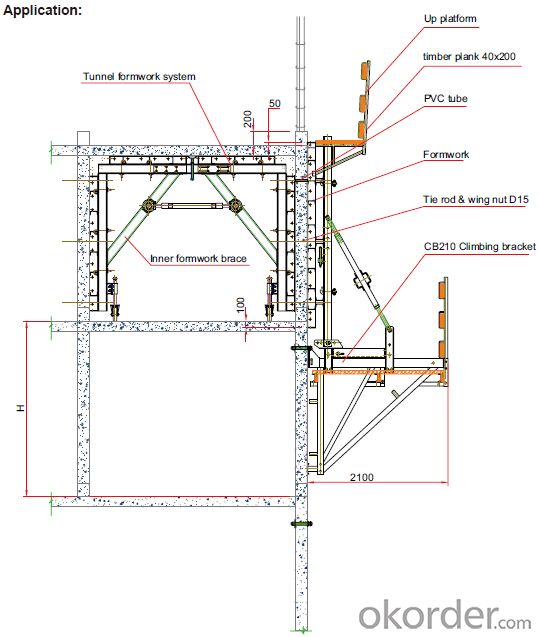

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q: The tunnel lining is wood, how should support?

- Two concrete tunnel lining, template is used according to the size and shape of the tunnel design custom-made, I-beam welded frame, welded steel plate, known as the "two trolley liner" (hydraulic jack lifting and installation of steel wheel moving on the rail), is generally the length of 9~12m, concrete pouring pump concrete.

- Q: I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- Tunnel lining trolley design software is CAD, the use of the software for the design of the structure

- Q: How to design the general layout of the tunnel construction organization design

- A very simple plane diagram, indicating the location of the tunnel, into the construction of the sidewalk and the construction of sidewalks, mixing stations and storage yard, air compressor unit location

- Q: What is the role of the grid steel frame and steel mesh in the power tunnel

- Function as follows:1, the construction of the shaft excavation of the power tunnel shaft structure is a permanent structure, the construction of the shaft using shotcrete + net structure steel frame + steel mesh support + waterproof film + cast-in-place reinforced concrete lining method.

- Q: The arch and the arch of the tunnel

- Tunnel invert refers to the bottom of the tunnel (anti arch, so called inverted arch)

- Q: What is the width of a ring in a tunnel

- Generally used in the tunnel as a two car lining template

- Q: What is the role of the tunnel formwork trolley? What is the use of template trolley?

- The car is often used in the construction of hydraulic tunnel, the tunnel is not allowed to have concrete construction longitudinal joints, in the hydraulic tunnel span is large

- Q: What are the steps? If you build a template, how to fill in the concrete. The tunnel is to dig all the generalist pouring, or digging into the side. Simply say. Better picture. In addition, we have seen a video, the shield machine to dig up the tunnel after the installation of a number of prefabricated panels, but these prefabricated plate is curved. Do not have to fill in a semicircle tunnel?

- Tunnel concrete is completed by the way of edge excavation and lining. After the excavation, the shotcrete is used as the initial support, and then the reinforcing steel mesh is set up. Only after the two lining.

- Q: In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Generally, a plurality of arc and straight steel die!Normal lining trolley

- Q: There are no recycling tunnel templates

- Tunnel template, as far as I understand, is the tunnel two lining template

Send your message to us

Building tunnel formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords