Steel Tunnel Formwork for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

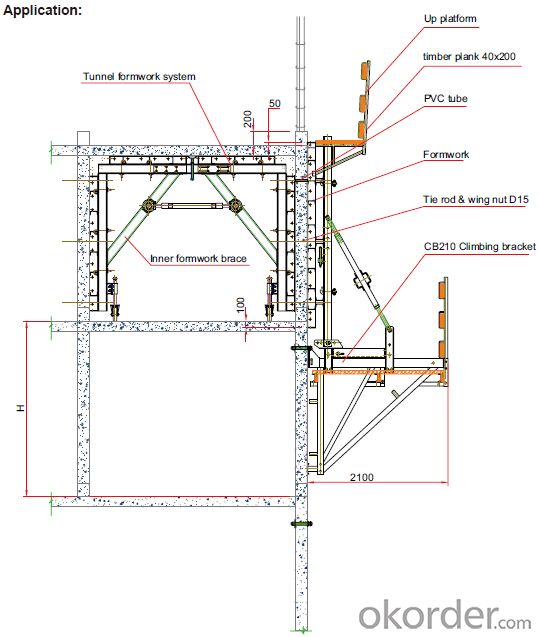

Building Tunnel Formwork:

A compositional steel formwork system mainly used in the building which has regular structure

without beams, the excellent formwork system can make the integral pouring for the wall & slab

easily achieved.

Characteristics:

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

- Q: I would like to ask the tunnel step method excavation, the height of each step is how to divide?

- The side ditch construction using composite steel formwork. (1) the temporary facilities of tunnel construction plan layout: in the single ended due to tunnel entrance, temporary facilities of tunnel construction in tunnel exit to the right. The layout for the layout of wind mechanical equipment in the right side of the roadbed export based on the terrain conditions, reservoir located in the left side from the position of about 80m. In the mechanical approach immediately after the entrance of earth excavation construction, roof slope and drainage ditches slope anchor slope reinforcement, well hole digging for. (2): the excavation and reinforcement the mechanical construction, according to the construction method of Subgrade Earthwork excavation, dig to the rock when, in order to minimize the disturbance of the entrance slope and subgrade slope, must adopt the method of weak blasting and presplitting blasting for excavation. The entrance slope using hang net shotcrete reinforcement, to facilitate the safety hole (3). The excavation and support of the shallow section of the surrounding rock of the cave: the construction method adopts the step method, and the advanced grouting bolt is adopted on the stage

- Q: The tunnel structure of plastic mould

- Tunnel construction, due to the wall and floor can be cast at the same time, therefore, the design of the building has the following requirements.(1) the width and height of the room should be relatively constant, and the thickness of the bearing wall should be consistent.(2) there are two longitudinal walls inside the corridor, and the upper and lower layers are thick enough to adjust the depth of the rooms on both sides.(3) the thickness of the floor should be kept constant.(4) the basic unit of the structure must be open on one side, and the large span can be opened on both sides.(5) the arrangement should be avoided in the plane.

- Q: Loess tunnel construction quality control points

- The main points of concrete construction of tunnel invert:1) should advance concrete arch wall concrete construction of inverted arch arch and the construction should be removed before water, slag and other sundries, false

- Q: For example, lining, invert, bias and so on words,, to answer the full thank you

- Inverted arch: the general shape of the tunnel are horseshoe. Then the bow that you look up at is called an arch or vault

- Q: How to put the positioning point is based on what is mainly based on my novice, do not

- The next two large positioning along the side mode, re positioning of two small side mode along the point, then turn to check the center point and elevation, if not the positioning deviation is complete, then re adjust the positioning deviation! If you have time to measure the location of the site can be set up, then you do not nail this method, the five points directly to the elevation and mileage can be controlled for a long time

- Q: Tunnel steel arch behind the steel mesh after a layer of fine iron wire mesh what effect is there?

- Function as follows:1, the construction of the shaft excavation of the power tunnel shaft structure is a permanent structure, the construction of the shaft using shotcrete + net structure steel frame + steel mesh support + waterproof film + cast-in-place reinforced concrete lining method.

- Q: What is the role of the tunnel formwork trolley? What is the use of template trolley?

- The utility model is mainly composed of a simple lining trolley, a full hydraulic automatic walking lining trolley and a grid type lining trolley. Full hydraulic lining trolley can be divided into the side and roof arch, circular needle beam, bottom mold, full circle needle beam through type etc.. It is also widely used in the construction of hydraulic tunnel and bridge that the lifting sliding mode, the lifting sliding mode and the turning mode, etc..

- Q: Demolition of tunnel bearing formwork for several days

- With the temperature, the need for concrete strength of 100% to remove the template

- Q: A detailed method is introduced

- The construction methods and technical measures2.1 construction processTo measure the slope, slope protection, Boulder rolling, processing or drainage construction, earthwork excavation, slope protection, inverted arch and side wall foundation construction, liming cave mould, steel banding, liming mould, pouring concrete, concrete outside the health to release, waterproof layer construction, backfilling and protection engineering construction.2.2 construction methods1) Myongdong and a complete portal excavation, excavation with full width transverse dredging method once formed, the first slopes, put the line before the excavation, then drain.2) with earthwork excavating, the small rock blasting method, drill hole, millisecond electric detonator, mucking loaders, dump truck transport, blasting near the slopes, with smooth blasting, in order to ensure the stability of slope. Excavation from top to bottom, side of the construction side slope excavation and slope into the face of the protection works.3) the first tunnel excavation after 10 ~ 20m, and then open cut tunnel lining. When construction, pay attention to Myeongdong and at the joint of the dark hole, from the inside out.4, before entering the cave, complete all slope reinforcement and protection measures.

- Q: What is the concrete construction of the tunnel invert

- The construction of concrete is related to the non - construction concrete

Send your message to us

Steel Tunnel Formwork for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords