Triangular Form Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

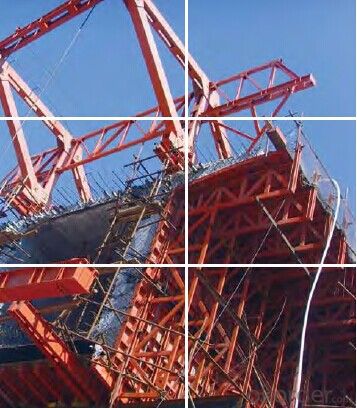

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

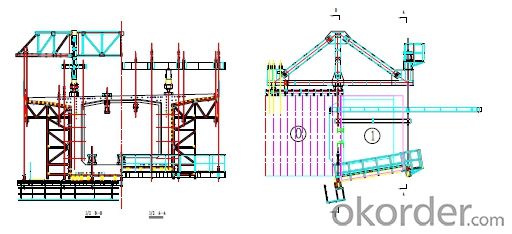

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: Car hanging basket, green, yellow different license, according to what standard hang

- Special vehicles: white red black; make,Consulate foreign car: black white and red "to" sign;Other foreign car: black white.

- Q: Under what circumstances the use of hanging basket construction under what circumstances with full support construction

- For some as far as possible to prefabricated parts, generally using prefabricated pieces of Oh, but according to the safety, economy and quality is more easy to monitor oh.

- Q: How does the prestressed tensioning in the construction of the bridge hanging basket?

- After pouring a concrete, such as the strength of the aging period, the tension of a paragraph, and then continue to the next section of constructionSpecific construction process and other prestressed construction process the same

- Q: Technical requirements for hanging baskets

- Two pier top 0 block bracket construction, the various parts of the welding quality of key inspection.

- Q: Hanging basket construction steel binding labor costs a ton of money

- Steel straight, processing, assembling, derusting, welding, sleeve connection, transportation, installation, transportation and other mold materials on-site and reinforced construction about everything related ancillary work

- Q: The hanging basket is the main equipment of the cantilever pouring construction of the bridge

- The hanging basket is the main equipment of the bridge cantilever pouring construction, usually consists of five parts, namely: the main truss, lifting system, formwork system, walking system, anchor system

- Q: There are transverse prestressed steel strand in the middle beam, the bridge has longitudinal steel strand, and the vertical line is finished steel. I would like to ask the next three pull sequence

- The general situation is to pull the first part of the prestressed steel strand

- Q: Seven techniques of hanging basket

- 10.5. tube. When the concrete is vibrated, we should pay attention to avoid the bellows to prevent the vibration rod from leaking;10.6. to nap. Because of concrete pouring, the surface still paving asphalt concrete, in order to enhance the bonding between the deck and asphalt layer layer of political government must firmly on the concrete surface roughening treatment:10.7. maintenance. After the concrete pouring, maintenance to improve the strength of concrete and prevent the formation of fine cracks, has an important role. Therefore, water conservation should not be less than seven days.

- Q: Can the vertical prestress of the hanging basket be tensioned after the subsequent section construction?

- Prestressed concrete structure, before the load in advance, put pressure on it, in the external load when the concrete tensile stress compressive stress produced in order to offset or reduce the load due to the tensile stress, the structure used in the normal circumstances does not crack or crack late.

- Q: Can you please list them ALL because I really need it for my book report =) thanks

- Dasher, Dancer, Prancer, Vixen... er, no, wait Happy, Sleepy, Dopey, Sneezy... er, no, wait sorry, I never read it, maybe YOU should

Send your message to us

Triangular Form Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords