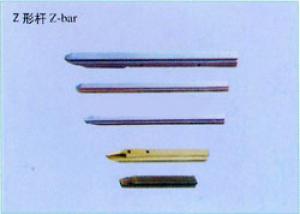

D Form Bar

D Form Bar Related Searches

Dia Bars Pre Drilled Flat Bar Inhibitor Bar Rough Formwork Moving Formwork Engineered Formwork System Faced Mdf Board Formwork Wall Formwork System Gliding Formwork System Formwork Esd Bag Rammed Earth Formwork Doka Formwork Board Room Table Green Formwork Materials For Formwork Striking Formwork Centering And Shuttering Form Work Fabric Formwork Peri Formwork System Conventional Formwork System Plywood Formwork Column Clamps Formwork Render Board Doka Formwork Usa Strongback Formwork Foundation Formwork Tmt Bars Doka Formwork AccessoriesD Form Bar Supplier & Manufacturer from China

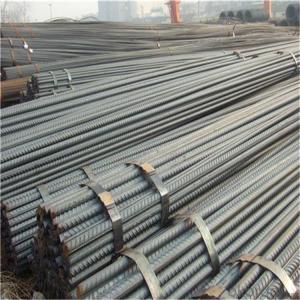

D Form Bar is a product that encompasses a variety of metal bars, including steel rebar, which is commonly used in construction projects. These bars are specifically designed to provide structural support and reinforcement to concrete structures, ensuring their stability and durability. The unique shape and design of D Form Bar allow for efficient load distribution, making it an ideal choice for various construction applications.D Form Bar is widely used in the construction industry for applications such as reinforcing concrete structures, building foundations, and creating strong, stable frameworks for buildings and bridges. Its versatility makes it suitable for both residential and commercial construction projects, as well as for infrastructure development. Contractors and engineers appreciate the ease of use and reliability that D Form Bar offers, contributing to the overall efficiency and safety of construction projects.

Okorder.com is a reputable wholesale supplier of D Form Bar, boasting a large inventory that caters to the diverse needs of the construction industry. By offering a comprehensive range of D Form Bar products, Okorder.com ensures that customers have access to the right materials for their specific projects. Their commitment to quality and customer satisfaction makes them a trusted source for D Form Bar and other construction supplies.

Hot Products