Chrome Added Deformed Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

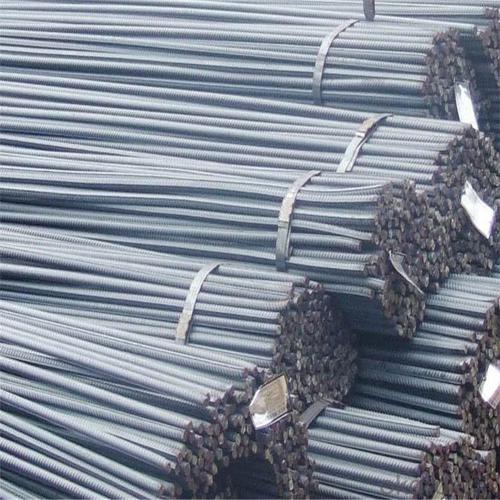

Chrome Added Deformed Steel Round Bars

Description of Chrome Added Deformed Steel Round Bars

1, Diameter: 5.5mm-10mm Chrome Added Deformed Steel Round Bars

10m- 40mm Chrome Added Deformed Steel Round Bars

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Chrome Added Deformed Steel Round Bars

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Chrome Added Deformed Steel Round Bars

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the common applications of stainless special steel?

- Stainless special steel, which is also known as stainless steel, possesses unique properties and characteristics that enable it to be extensively utilized in a wide range of applications. Some of the common uses of stainless special steel include: 1. In the construction industry, stainless steel is favored by architects and engineers for building facades, roofing, and structural components due to its high strength, corrosion resistance, and aesthetic appeal. 2. Within the automotive industry, stainless steel is extensively employed in the manufacturing of exhaust systems, mufflers, fuel tanks, and decorative trims, thanks to its resistance to corrosion, heat, and impact. 3. The aerospace industry utilizes stainless steel for the production of aircraft components such as frames, engine parts, and landing gear. This is due to stainless steel's exceptional strength-to-weight ratio, high-temperature resistance, and corrosion resistance, which make it suitable for the demanding conditions of aerospace applications. 4. In the medical industry, stainless steel is widely used for the manufacture of surgical instruments, implants, and medical equipment. Its biocompatibility, corrosion resistance, and ease of sterilization make it an ideal material for critical medical applications. 5. The food processing industry relies heavily on stainless steel for the manufacturing of storage tanks, pipes, and containers. This is because stainless steel possesses hygienic properties, corrosion resistance, and is easy to clean, ensuring the integrity and safety of food products. 6. The chemical industry makes extensive use of stainless steel due to its resistance to corrosion from various chemicals and acids. It is employed in the production of storage tanks, pipes, valves, and other equipment required in chemical processing plants. 7. In the marine industry, stainless steel is widely employed for manufacturing boat fittings, propellers, and underwater structures. Its resistance to corrosion from saltwater and harsh marine environments make it an excellent choice for marine applications. 8. The energy industry utilizes stainless steel in the manufacturing of pipelines, valves, and heat exchangers. Its high-temperature resistance, corrosion resistance, and durability make it suitable for use in power plants, oil refineries, and nuclear facilities. In summary, stainless special steel is a versatile material with exceptional properties, including corrosion resistance, strength, durability, and aesthetic appeal. This versatility allows it to find applications in various industries.

- Q: What are the different passivation techniques used for special steel?

- There are several passivation techniques used for special steel, including chemical passivation, electrochemical passivation, and mechanical passivation. Chemical passivation involves the use of acidic solutions to remove impurities from the steel's surface and create a passive oxide layer. Electrochemical passivation utilizes an electrical current to form the protective oxide layer on the steel's surface. Mechanical passivation involves processes such as shot blasting or grinding to remove contaminants and improve the surface quality of the steel. These techniques help enhance the corrosion resistance and overall performance of special steel.

- Q: How is special steel used in the production of cutting blades?

- Special steel is used in the production of cutting blades due to its exceptional properties, such as high hardness, toughness, and wear resistance. These properties allow the cutting blades to maintain their sharpness and durability even when subjected to intense cutting forces and repeated use. The special steel's composition and heat treatment processes ensure that the cutting blades are capable of withstanding harsh operational conditions, resulting in efficient and precise cutting performance across various industries, including manufacturing, construction, and agriculture.

- Q: How does special steel contribute to the manufacturing of bearings?

- The importance of special steel in bearing manufacturing cannot be overstated. This type of steel, also known as bearing steel, is specifically designed to meet the demanding requirements of bearings. First and foremost, special steel offers exceptional hardness, which is crucial for bearings to endure heavy loads and high-speed rotations. This hardness allows the bearings to resist wear and deformation, resulting in a longer lifespan and reliable performance. In addition, special steel possesses excellent corrosion resistance. Bearings often operate in harsh environments where they are exposed to moisture, chemicals, and other corrosive substances. The special steel used in their production effectively prevents rust and deterioration, ensuring that the bearings can withstand these challenging conditions. Furthermore, special steel has superior heat resistance and thermal stability. Bearings can generate significant heat during operation due to friction and pressure. The special steel used in their production can withstand high temperatures without losing its structural integrity, preventing premature failure and ensuring consistent performance. Moreover, special steel offers exceptional strength and toughness. These properties are vital for bearings to withstand the intense forces and impacts they experience during operation. The high strength and toughness of the steel prevent fractures, breakages, and other forms of damage, contributing to the overall durability and reliability of the bearings. Lastly, special steel has excellent dimensional stability and machinability. This allows for precise manufacturing and shaping of the bearing components, ensuring accurate dimensions and smooth surfaces. The dimensional stability of the steel ensures that the bearings can maintain their proper fit and alignment within the machinery, minimizing any potential issues or malfunctions. In conclusion, the unique properties of special steel make it indispensable in bearing manufacturing. Its hardness, corrosion resistance, heat resistance, strength, toughness, dimensional stability, and machinability enable bearings to withstand various challenging conditions, ensuring their reliable and efficient operation in a wide range of applications.

- Q: What are the future trends in special steel manufacturing?

- Some of the future trends in special steel manufacturing include advancements in technology and automation, increased focus on sustainability and environmental impact, development of new alloys and materials with enhanced properties, and growing demand for specialized steels in industries like aerospace, automotive, and renewable energy. Additionally, there is a shift towards customization and tailored solutions to meet specific customer requirements, as well as an emphasis on research and development to drive innovation in the field.

- Q: What are the applications of special steel in the electronics industry?

- Special steel is widely used in the electronics industry due to its unique properties and benefits. Some of the applications of special steel in this industry include the manufacturing of electronic components, such as connectors, springs, and contacts, which require high strength and corrosion resistance. Special steel is also used in the production of magnetic cores for transformers and inductors, as it exhibits excellent magnetic properties. Additionally, special steel is utilized in the fabrication of precision tools and equipment used in electronics manufacturing processes, ensuring high precision, durability, and reliability. Overall, the applications of special steel in the electronics industry contribute to enhanced performance, efficiency, and longevity of electronic devices and systems.

- Q: How does special steel contribute to the automotive noise reduction?

- Special steel contributes to automotive noise reduction in several ways. Firstly, it is used in the manufacturing of the vehicle's structure and body, providing high strength and stiffness, which helps reduce vibrations and noise transmission. Additionally, special steel can be used in the production of engine components, such as exhaust systems, mufflers, and catalytic converters, which help dampen and absorb noise generated by the engine. Furthermore, the use of special steel in the construction of suspension systems and other mechanical components can also contribute to minimizing noise and vibrations, resulting in a quieter and more comfortable driving experience.

- Q: Can special steel be used in the cement manufacturing industry?

- Yes, special steel can be used in the cement manufacturing industry. Special steel, such as heat-resistant and wear-resistant steel, can be utilized in various components and machinery used in cement manufacturing processes. These steels are designed to withstand high temperatures, abrasion, and corrosion, making them suitable for applications in kilns, crushers, mills, and other equipment involved in cement production.

- Q: How does heat-resistant steel perform in high-temperature applications?

- Heat-resistant steel performs well in high-temperature applications as it retains its mechanical properties, such as strength and hardness, at elevated temperatures. It exhibits excellent resistance to thermal fatigue, oxidation, and creep, making it suitable for applications where exposure to extreme heat and stress is common. Additionally, heat-resistant steel maintains dimensional stability and can withstand thermal cycling without significant deformation or degradation, ensuring long-term reliability in high-temperature environments.

- Q: How does special steel contribute to improving product sustainability?

- Special steel contributes to improving product sustainability in various ways. Firstly, special steel is known for its durability and strength, which enables products made from it to have a longer lifespan. This reduces the need for frequent replacements, minimizing waste and conserving resources. Additionally, special steel is highly recyclable, allowing it to be reused and transformed into new products, thus reducing the demand for virgin materials. Furthermore, special steel's resistance to corrosion and wear makes it suitable for harsh environments, reducing maintenance requirements and extending product lifecycles. Overall, the use of special steel enhances product sustainability by promoting longevity, resource conservation, and circular economy principles.

Send your message to us

Chrome Added Deformed Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords